Flexible multi-hole metal foil and manufacturing method thereof

A porous metal and flexible technology, applied in the field of sintered metal porous materials and their preparation, can solve problems such as limited use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

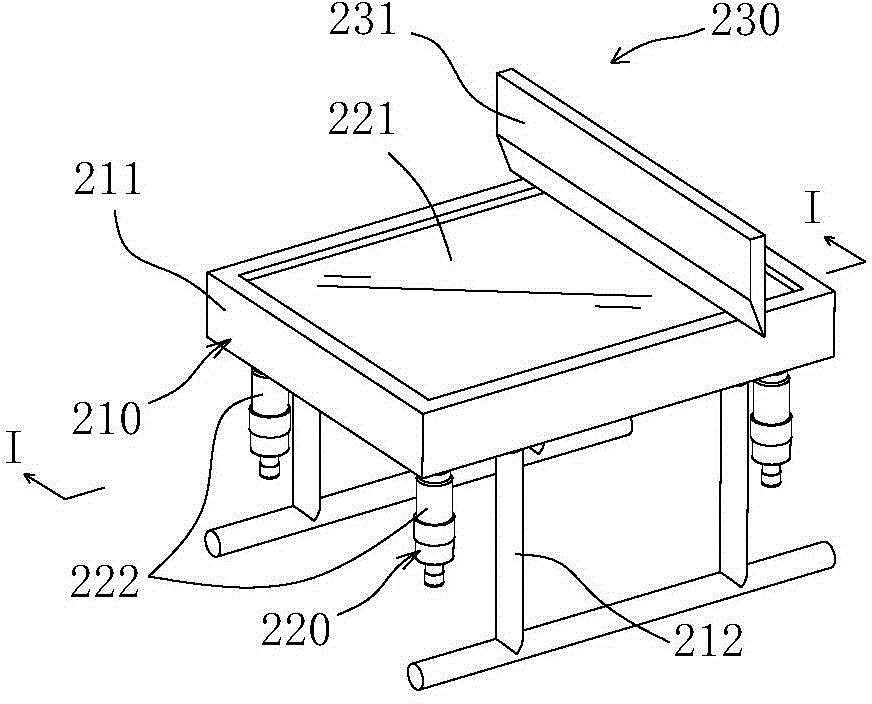

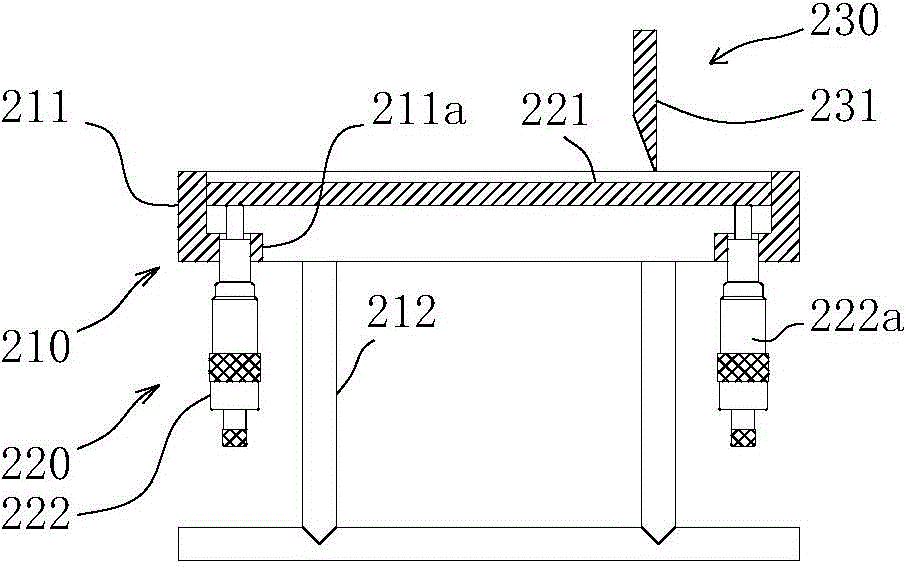

[0040] The steps of the preparation method of the flexible porous metal foil 100 include: (1) configuring the raw material powder constituting its metal porous material into a viscous suspension with a dispersant and a binding agent; (2) dissolving the suspension The liquid is injected into the molding cavity of the film-making tooling and dried to form a homogeneous membrane; (3) the membrane is placed in a sintering tool that matches the shape of the membrane, and then constrained sintering is carried out. Take it out from the sintering tool and obtain the flexible porous metal foil 100 .

[0041] In the above method, the dispersant can use ethanol, methyl ethyl ketone, toluene and other organic solvents with low surface tension and quick volatilization and easy drying; the binding agent can use PVB, PVA, PVC, polyvinyl alcohol, polyethylene glycol (low molecular wax) ), paraffin, fatty acids, aliphatic amides and esters, etc.

[0042] In the above method, the ratio between...

Embodiment 1

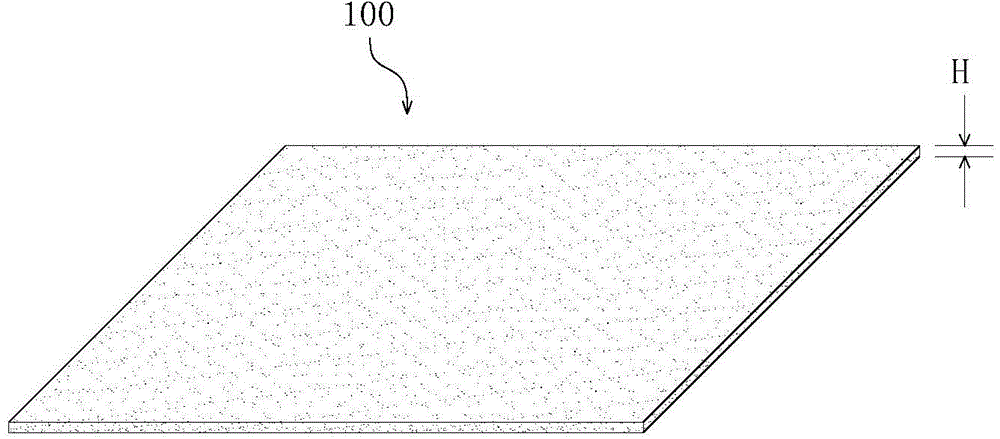

[0058] The flexible porous metal foil 100 is a rectangular sheet made of Ni-Cu solid solution alloy porous material. The sheet has a thickness H of 10 μm, a length of 160 mm, a width of 125 mm, an average pore diameter of 18.4 μm, and a porosity of 58.37%. The preparation method of the flexible porous metal foil 100 is as follows: First, uniformly mix Ni powder and Cu powder to form raw material powder, wherein the mass of Cu powder is 30% of the mass of the raw material powder, and then use ethanol as a dispersant and PVB as a binder , the mass ratio of PVB and ethanol is 2.5:100 ratio that PVB is added in the ethanol to make PVB solution, after this adds raw material powder in the PVB solution by the ratio of adding raw material powder 25g in every 100ml ethanol, makes raw material powder by stirring Fully disperse evenly to obtain a viscous suspension; secondly, inject the suspension into such as Figure 2~3 In the molding cavity of the shown film-making tooling and make it...

Embodiment 2

[0060] The flexible porous metal foil 100 is a rectangular sheet made of Ni-Cu solid solution alloy porous material. The sheet has a thickness H of 100 μm, a length of 200 mm, a width of 130 mm, an average pore diameter of 30 μm, and a porosity of 61.68%. The preparation method of the flexible porous metal foil 100 is as follows: First, uniformly mix Ni powder and Cu powder to form raw material powder, wherein the mass of Cu powder is 60% of the mass of the raw material powder, and then use ethanol as a dispersant and PVB as a binder , the mass ratio of PVB and ethanol is the ratio of 4:100 that PVB is added in the ethanol to make PVB solution, then adds raw material powder in the PVB solution by the ratio of adding raw material powder 40g in every 100ml ethanol, makes raw material powder by stirring Fully disperse evenly to obtain a viscous suspension; secondly, inject the suspension into such as Figure 2~3 In the molding cavity of the shown film-making tooling and make it d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com