A production process of cast iron and magnesium or aluminum alloy radiator

A production process, aluminum alloy technology, applied in the direction of rotors, engine components, pistons, etc., can solve the problems of not giving technical data, not being able to perform perfectly comprehensively, etc., to prevent hot water from directly contacting the human body, uniform heat dissipation, and heat conduction. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

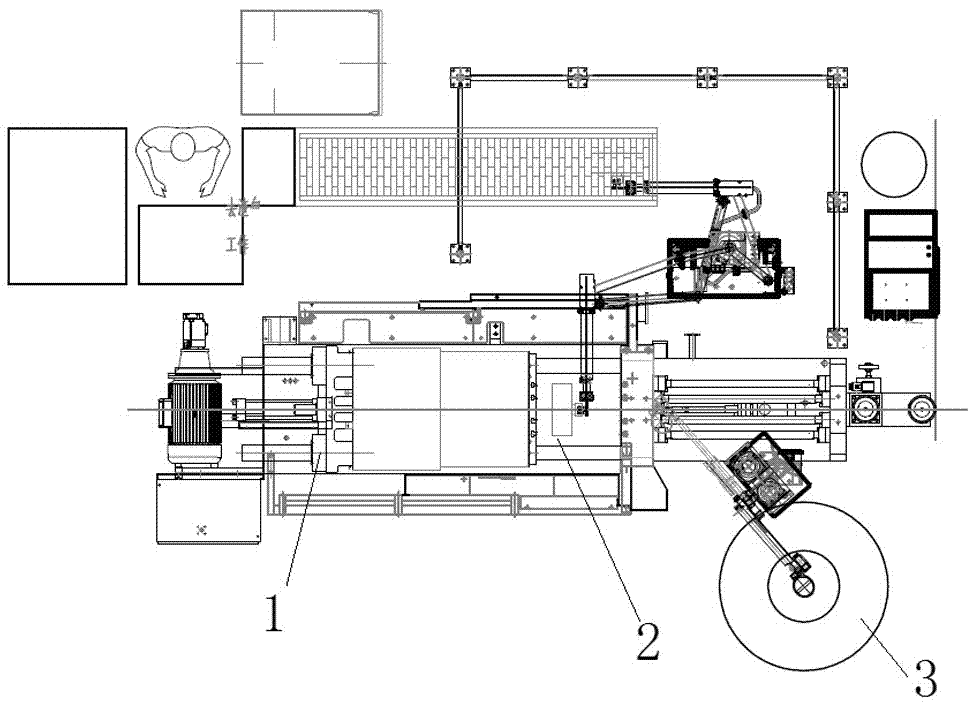

[0011] Embodiment 1, a kind of cast iron magnesium alloy radiator production process, the raw material used, nodular cast iron I-shaped core pipe, magnesium alloy raw material; Use equipment, core pipe mold, casting mold and cold chamber die-casting machine; Described casting mold, Such as figure 1 As shown, the structure of the core tube is I-shaped, and the core tube mold is used for integral casting; the I-shaped core tube cannot be prepared by welding.

[0012] Start the cold chamber die-casting machine, put the movable mold and the fixed mold of the casting mold on the movable mold fixed plate 2 and the fixed mold fixed plate 1 respectively, use the mold temperature controller to heat the casting mold to 200-270 degrees Celsius, and then turn on the power to melt the magnesium alloy The raw material is heated in the electric furnace 3 to a liquid state (600-700°C). The magnesium alloy liquid is injected into the mold cavity through a quantitative pump, and 5-10 pieces of ...

Embodiment 2

[0013] Embodiment 2, a kind of cast iron aluminum alloy radiator production process, the raw material used, nodular cast iron I-shaped core tube, aluminum alloy raw material; Use equipment, core tube mold, casting mold and cold chamber die-casting machine; Described casting mold, Such as figure 1 As shown, the structure of the core tube is I-shaped, and the core tube mold is used for integral casting; the I-shaped core tube cannot be prepared by welding.

[0014] Start the cold chamber die-casting machine, place the movable mold and the fixed mold of the casting mold on the movable mold fixed plate 2 and the fixed mold fixed plate 1 respectively, use the mold temperature controller to heat the casting mold to 200-270 degrees Celsius, and then power on the aluminum alloy The raw material is heated in the electric furnace 3 to a liquid state (550-650°C), and the aluminum alloy liquid is injected into the cavity of the mold through a quantitative pump, and 5-10 radiator waste pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com