Die for spinning and casting aluminum alloy wheel

A technology for casting aluminum alloys and molds, which is applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems that the length of the heating rod should not be too long, the blank has changes, and the heating efficiency has decreased, so as to prevent the failure to return smoothly, The effect of solving the inconsistent inner diameter and reducing the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

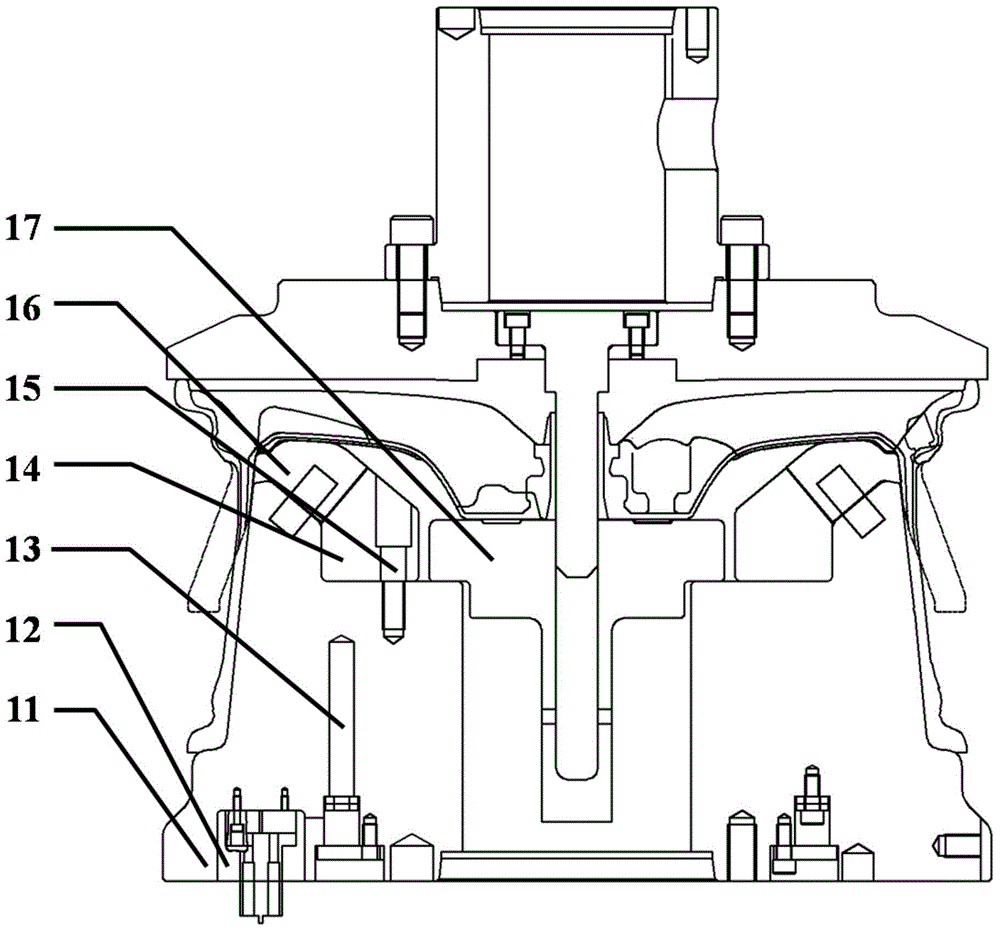

Embodiment 1

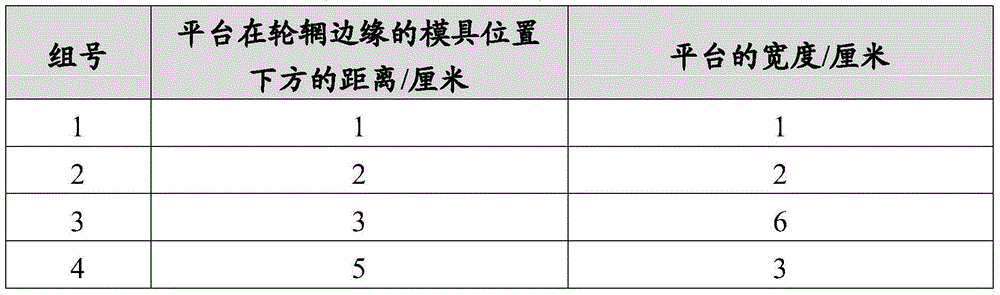

[0033] A mold lower mold for spin casting aluminum alloy wheels, the lower mold further includes a platform below the mold position corresponding to the edge of the wheel rim. Carry out the processing of lower mold platform according to the parameter shown in table 1:

[0034] Table 1: Processing parameters of the lower mold platform of the mold for spinning cast aluminum alloy wheels

[0035]

[0036] The test proves that the lower mold also includes a platform under the mold position corresponding to the edge of the rim to prevent the uneven end surface of the wheel after spinning and affect the heat treatment of the blank. The test in the pilot production line shows that compared with no platform, Groups 1-4 can reduce the scrap rate caused by uneven end faces by more than 65%, bringing unexpected excellent results. Among them, group 2 reduced the scrap rate caused by uneven end faces by 83%.

Embodiment 2

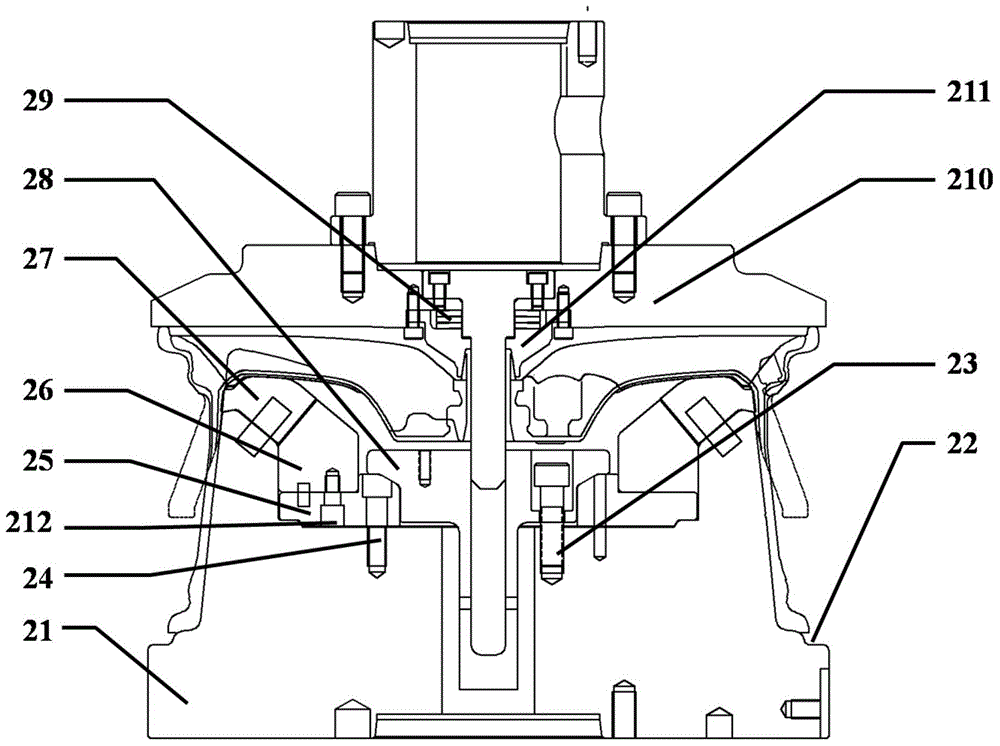

[0038] A mold lower mold for spin casting aluminum alloy wheels, the lower mold includes a backing plate 25, a guide block 26 and a loose block 27 at the wheel well, and the backing plate 25 is fixed to the bottom mold 21 by bolts 24, and the guide block 26 It is fixed to the backing plate 25 by bolts 212 .

[0039] Carry out the processing of lower mold according to the parameter shown in table 2:

[0040] Table 2: Processing parameters of the lower mold platform of the mold for spinning cast aluminum alloy wheels

[0041] Group No

[0042] The test in the pilot production line shows that the connection between the block and the new lower die, adding a backing plate, adjusted the matching gap between it and the loose block, making the loose block easier to install and position and expand smoothly. Through the connection between the guide block and the new lower die, adding a backing plate can effectively solve the effective expansion of the slider, solve the probl...

Embodiment 3

[0044] A mold lower mold for spin casting aluminum alloy wheels, the lower mold includes an induction heater and does not include a heating rod. At the same time, a lower mold ejector 28 is also included in the lower mold, and the lower mold ejector 28 is connected to the lower mold main body 21 by bolts 23 .

[0045] The test in the pilot production line shows that by removing the heating rod of the lower mold, the mold processing time is reduced and the production efficiency is improved. Compared with the original production time of the lower mold, after changing to the induction heater, the mold processing time is reduced by 27%, and the work efficiency is significantly improved.

[0046] At the same time, the induction heating method overcomes the uneven heating of the original heating rod. When the lower mold heated by induction heating is used in the pilot production line, the number of defective parts of the wheel is reduced by 25.2%, which brings great economic and so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com