Fuel waste recovery and treatment system

A technology of recycling and waste residue, applied in the field of environmental protection technology, can solve problems such as soil composition, soil structure damage, excessive resource consumption, environmental pollution, etc., and achieve the effect of reducing the development of resource land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

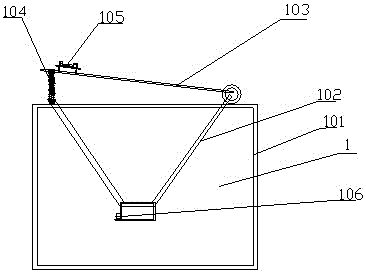

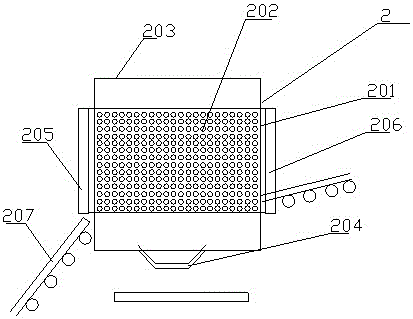

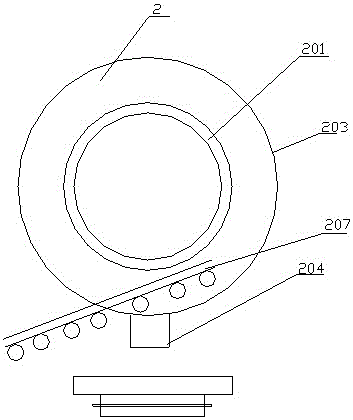

[0032] Referring to illustrations 1 to 12, a fuel waste residue recovery and treatment system includes a grid screen device 1 connected by a conveyor belt, a circular screen device 2, a magnetic separator for removing iron filings 3, a material water separation device 4, a crusher 10, Water separation removal iron filings device 5, jig machine 9, shaking table 6, disc sand removal device 7, vibration dehydrator 8, material warehouse;

[0033] The grid screen device 1 is erected on a pit 101, the grid screen device includes a conical silo 102, and an oblique grid screen 103 is erected above the conical silo 102, One side of the grid sieve 103 is hinged with the conical feed bin 102, and the other side is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com