Catalyst for synthesizing 3-buten-1-ol through 1,4-butanediol and preparation method of catalyst

A catalyst, butanediol technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that affects the purity of the product 3-buten-1-ol and other problems, to achieve the effect of easy large-scale production, less by-products, and a single type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

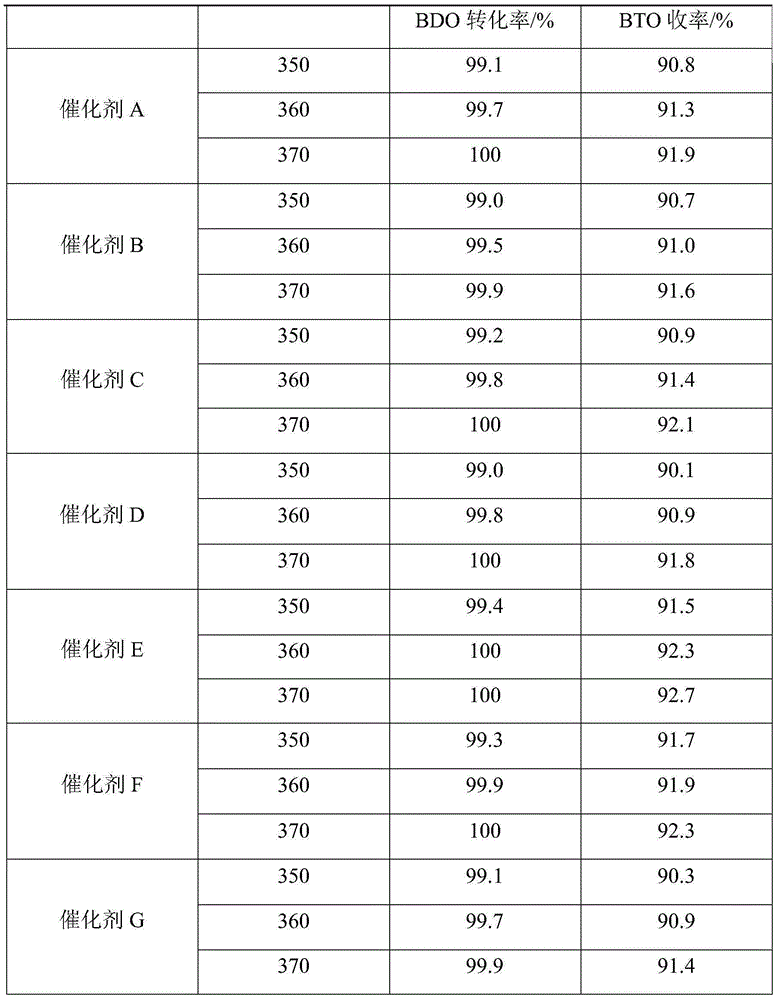

Examples

Embodiment 1

[0020] Measure 0.2ml of tetraethyl orthosilicate, dissolve it in 100ml of alcohol-water mixture with a volume ratio of 6:1 (concentration of tetraethyl orthosilicate is 0.008mol / L), put it in a constant temperature water bath at 60°C and stir for 10 minutes , add 0.19g of acetic acid solution, and continue to stir at constant temperature for 2h to obtain a silicon solution; weigh 21.17g of zirconyl nitrate, dissolve it in 100ml of alcohol-water mixture with a volume ratio of 6:1 (the concentration of zirconyl nitrate is 0.792mol / L) , placed in a 60°C constant temperature water bath and stirred for 1 hour to obtain a zirconium solution; the prepared zirconium solution was added to a silicon solution, placed in a 60°C water bath, stirred, gelled, and aged for 30 minutes to obtain a colloid; weigh 11.81g of Ca(NO 3 ) 2 .4H 2 O is dissolved in water and prepared as Ca at a concentration of 1 mol / L 2+ Solution, simultaneously weigh 49.53g of ammonium carbonate and dissolve in wat...

Embodiment 2

[0022] Prepare the catalyst according to the method of Example 1, replace 0.2ml tetraethyl orthosilicate with 1.1369g sodium silicate nonahydrate, change the alcohol-water volume ratio of the prepared silicon solution and zirconium solution to 4:1, and replace 0.19g acetic acid solution with 0.584g of concentrated hydrochloric acid instead, after drying, roasting, and cooling to room temperature, catalyst B was obtained.

Embodiment 3

[0024] Prepare the catalyst by the method of Example 2, change the amount of zirconyl nitrate to 20.31g, replace 11.81g calcium nitrate tetrahydrate with 8.60g calcium sulfate dihydrate, replace 49.53g ammonium carbonate with 12.19g sodium carbonate, and dry , roasting, and after cooling to room temperature, catalyst C is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com