Formation method and preparation method of high-voltage lithium ion battery as well as battery

A technology of lithium ion battery and formation method, applied in the field of lithium ion battery, can solve the problems of increased SEI film growth thickness, long battery production cycle, increased battery internal resistance, etc., to achieve easy industrial application, reduce impedance, and prolong cycle life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

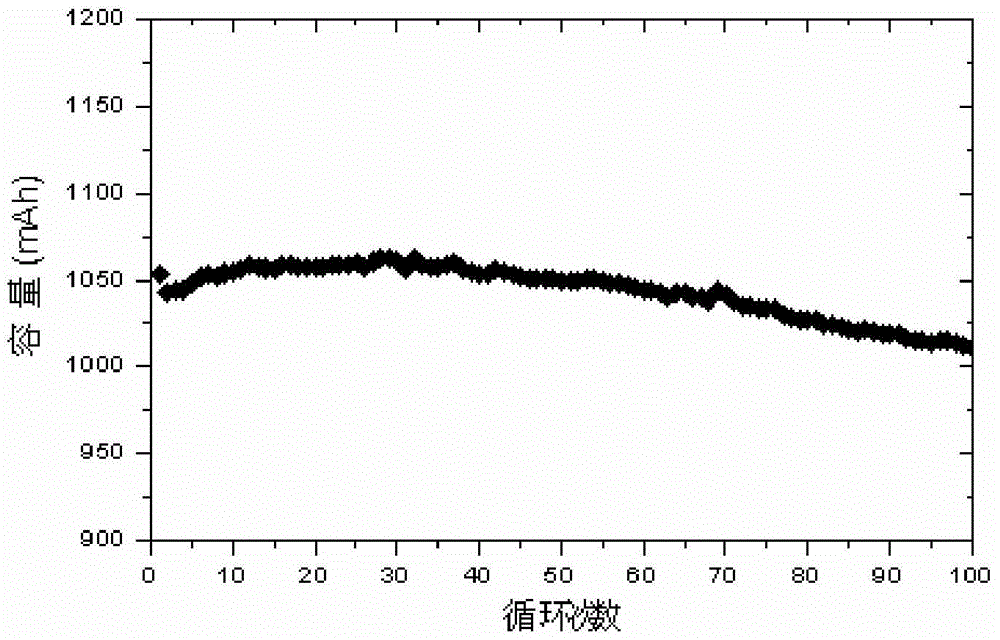

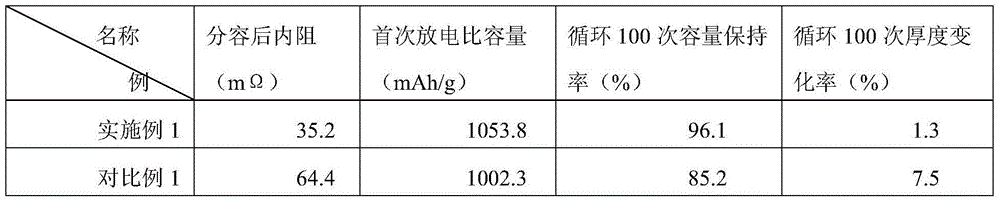

Embodiment 1

[0028] In this example, LiNi 0.5 mn 1.5 o 4 As the positive electrode material, the positive electrode material LiNi 0.5 mn 1.5 o 4 , Conductive agent acetylene black, binder polyvinylidene fluoride (PVDF) according to the mass ratio of 93:2:5 ingredients, to make the positive plate; artificial graphite as the negative material, the negative material artificial graphite, conductive agent acetylene black, water-based The adhesive LA132 is mixed according to the mass ratio of 94.5:1:4.5 to make the negative electrode sheet; the above positive and negative electrode sheets are assembled into the same battery, the designed battery capacity is 1Ah, and the median voltage is 4.5V to obtain a high-voltage lithium battery. Ion battery, that is, spinel lithium nickel manganese oxide battery.

[0029] This embodiment provides a spinel lithium nickel manganese oxide battery formation method, including the following formation process steps:

[0030] (1) Charge with 0.02C constant cu...

Embodiment 2

[0048] In this example, LiNi 0.5 mn 1.5 o 4 As the positive electrode material, the positive electrode material LiNi 0.5 mn 1.5 o 4 , the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) are mixed according to the mass ratio of 95:2:3 to make the positive electrode sheet; the Si / C composite material is used as the negative electrode material, and the negative electrode material Si / C composite material, The conductive agent acetylene black and the water-based adhesive LA132 are mixed according to the mass ratio of 92:3:5 to make the negative electrode sheet; the above-mentioned positive and negative electrode sheets are assembled into the same battery, and the designed battery capacity is 1Ah, and the median voltage is 4.4 V, to obtain a high-voltage lithium-ion battery, that is, a spinel lithium nickel manganese oxide battery.

[0049] This embodiment provides a method for forming a spinel lithium nickel manganese oxide battery, comprising t...

Embodiment 3

[0059] In this example, Li 1.2 Ni 0.25 mn 0.75 o 2.35 As the positive electrode material, the positive electrode material Li 1.2 Ni 0.25 mn 0.75 o 2.35 , Conductive agent acetylene black, binder polyvinylidene fluoride (PVDF) according to the mass ratio of 93:1.5:5.5 ingredients to make the positive plate; use natural graphite as the negative electrode material, the negative electrode material natural graphite, conductive agent acetylene black, water-based Adhesive LA132 is mixed according to the mass ratio of 92:3:5 to make the negative electrode sheet; the above-mentioned positive and negative electrode sheets are assembled into the same battery, the designed battery capacity is 2Ah, and the median voltage is 3.3V to obtain high-voltage lithium Ion battery, that is, spinel lithium nickel manganese oxide battery.

[0060] This embodiment provides a method for forming a spinel lithium nickel manganese oxide battery, comprising the following steps:

[0061] (1) Charge w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com