Method for preparing nano bowl-shaped phase change memory unit

A phase change memory, nano bowl technology, applied in nanotechnology, nanotechnology, nanotechnology for information processing, etc., to achieve the effects of reducing energy loss, reducing the range of heat diffusion, and increasing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

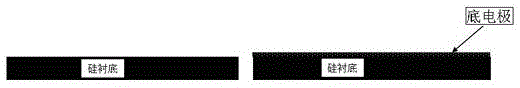

[0024] ①. Put the Si or quartz substrate on the NH 4 OH (analytical pure), H 2 o 2 (analytically pure) and H 2 The mixed solution composed of O (volume ratio 1:2:6) was boiled for 5 minutes, then rinsed with deionized water and dried in an oven. On the dried Si or quartz substrate, the magnetron sputtering technology is used to grow the conductive thin film TiN or W with a thickness of 10 nm to form the bottom electrode ( figure 1 ). TiN or W thin films were prepared in a magnetron sputtering system (model ATC 1800-F, USA AJA) produced in the United States. The background pressure in the magnetron sputtering system is 1.8×10 ?6 Torr, the sputtering pressure is 2mTorr, Ar gas is used as the shielding gas, and the sputtering power is 20 watts. At this time, the sputtering rate of TiN was 0.049 nm / s (the sputtering rate of W was 0.057 nm / s).

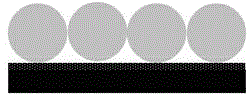

[0025] ②. Soak the bottom electrode in step ① in a 10% sodium lauryl sulfate solution for 24 hours, so that we can get a hydrophil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com