Asymmetric supercapacitor with potassium ferricyanide and potassium ferrocyanide added to two electrode chambers respectively and preparation method thereof

A supercapacitor and potassium ferrocyanide technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor separators, etc., can solve problems such as unfavorable capacitor performance, low solubility, and increased self-discharge. Achieve excellent cycle stability, high solubility, and improved capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

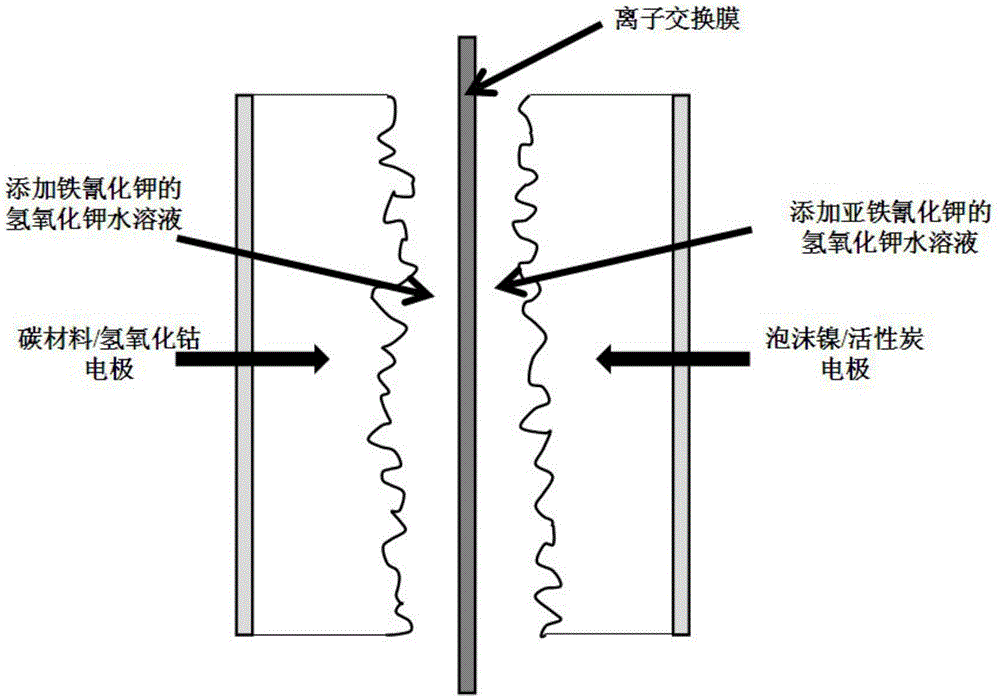

[0044] (1) Use an area of 1cm 2 Carbon paper was used as the base, soaked in acetone, ethanol, and deionized water for 2 hours, and then ultrasonicated for 30 minutes. Carbon paper / cobalt hydroxide electrodes were prepared by potentiostatic electrodeposition. During the electrochemical deposition process, the concentration of cobalt nitrate was 1.2mol / L, the deposition time was 1h, the deposition potential was -0.9V, and the temperature was 45°C.

[0045] (2) Use an area of 1cm 2 Nickel foam was used as the substrate, soaked in acetone, ethanol, and deionized water for 2 hours, and then ultrasonicated for 30 minutes. Nickel foam / activated carbon electrodes were prepared by doctor blade method. Mix activated carbon, conductive graphite and Nafion solution evenly in a mass ratio of 85:10:5, and scrape them on the nickel foam.

[0046] (3) The supercapacitor diaphragm ion exchange membrane is treated, specifically, the volume fraction of hydrogen peroxide is 5%, the treat...

Embodiment 2

[0050] (1) Use an area of 100cm 2 Carbon paper was used as the base, soaked in acetone, ethanol, and deionized water for 2 hours, and then ultrasonicated for 30 minutes. Carbon paper / cobalt hydroxide electrodes were prepared by potentiostatic electrodeposition. During the electrochemical deposition process, the concentration of cobalt nitrate was 1.2mol / L, the deposition time was 1h, the deposition potential was -0.9V, and the temperature was 45°C.

[0051] (2) Use an area of 100cm 2 Nickel foam was used as the substrate, soaked in acetone, ethanol, and deionized water for 2 hours, and then ultrasonicated for 30 minutes. Nickel foam / activated carbon electrodes were prepared by doctor blade method. Mix activated carbon, conductive graphite and Nafion solution evenly in a mass ratio of 85:10:5, and scrape them on the nickel foam.

[0052] (3) The supercapacitor diaphragm ion exchange membrane is treated, specifically, the volume fraction of hydrogen peroxide is 5%, the t...

Embodiment 3

[0055] (1) Same as Embodiment 2 (1).

[0056] (2) is the same as Embodiment 2 (2).

[0057] (3) is the same as Embodiment 2 (3).

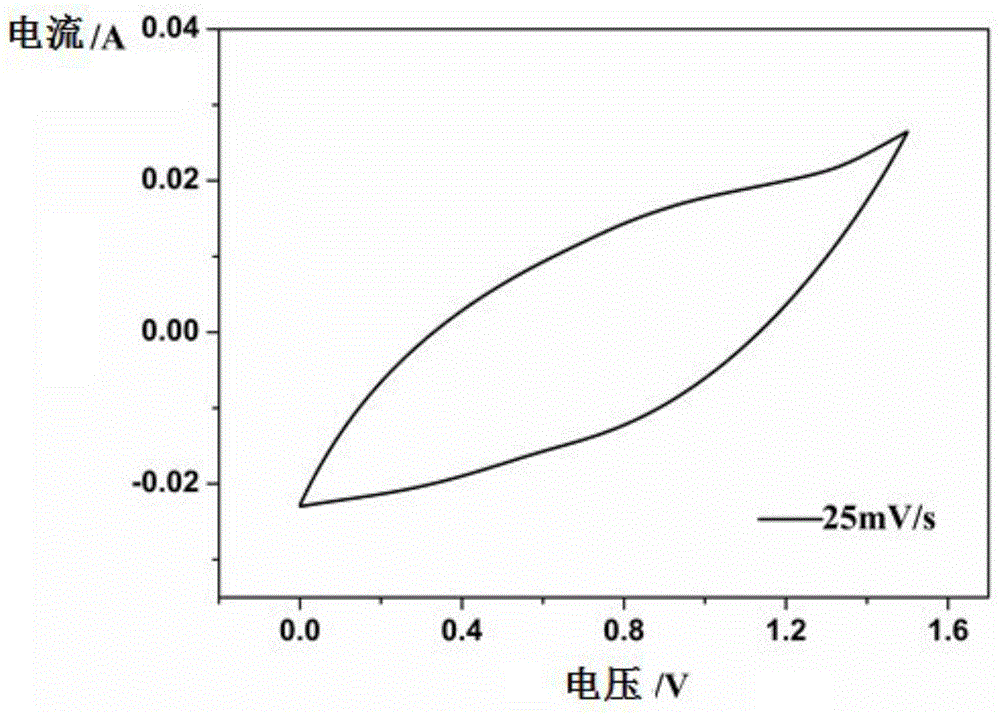

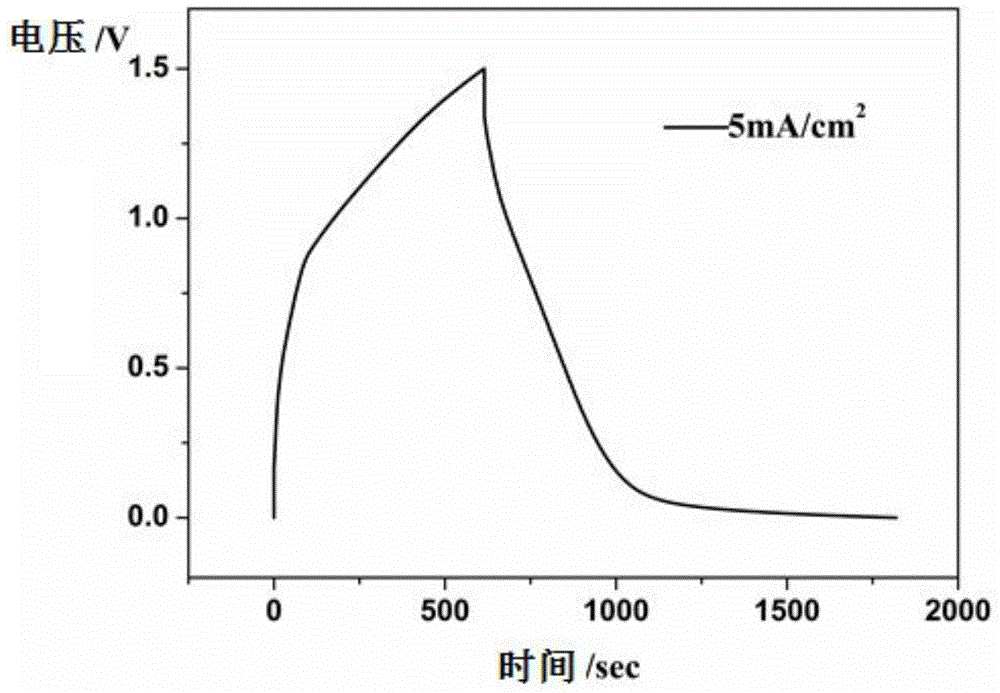

[0058] (4) The carbon paper / cobalt hydroxide electrode is used as the positive electrode, the nickel foam / activated carbon electrode is used as the negative electrode, and the ion exchange membrane is used as the diaphragm, and 50ml of 1mol / L KOH and 0.05mol / L KOH are injected into the positive electrode. 3 Fe(CN) 6 The mixed solution of the negative electrode is injected with 50ml of 1mol / L KOH and 0.05mol / L of K 4 Fe(CN) 6 The mixed solution is assembled into a bipolar chamber and the oxidizing agent and reducing agent are respectively added, and the electrode area is 100cm 2 A novel cobalt hydroxide-activated carbon asymmetric capacitor. The above-mentioned new asymmetric capacitor is charged and discharged, the maximum potential window is 1.6V, and the current density is 1mA / cm 2 , the specific capacitance and energy density of the new ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Charge and discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com