Magnetic cores, chip inductor with magnetic cores and manufacturing method

A manufacturing method and magnetic core technology, applied in the direction of inductance with magnetic core, inductance/transformer/magnet manufacturing, transformer/inductor magnetic core, etc., can solve the damage of ferric oxide material, low product yield, vibration And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

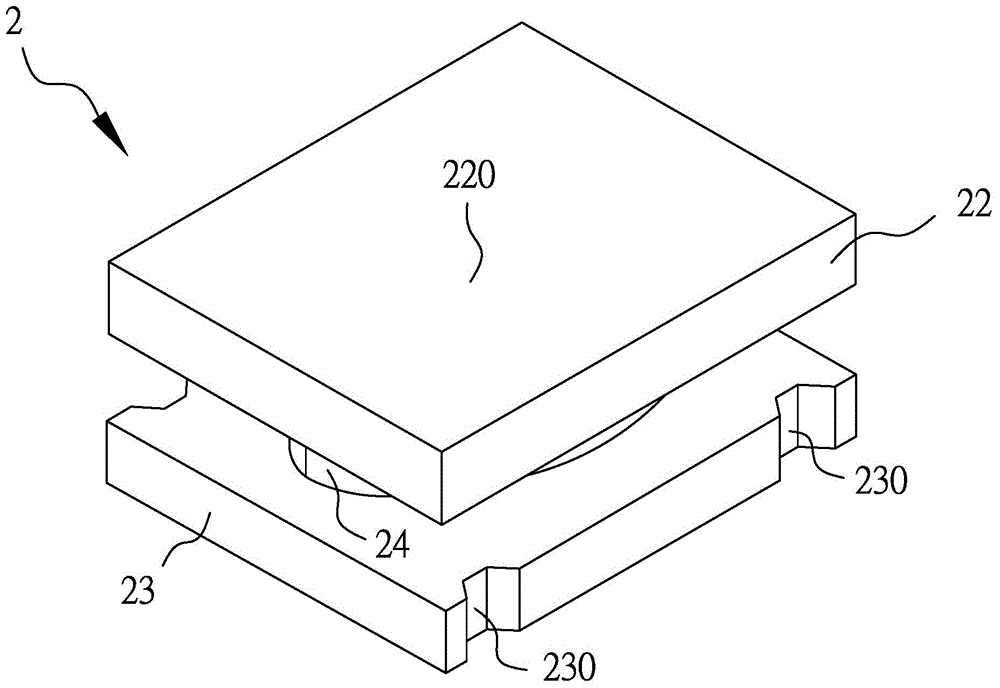

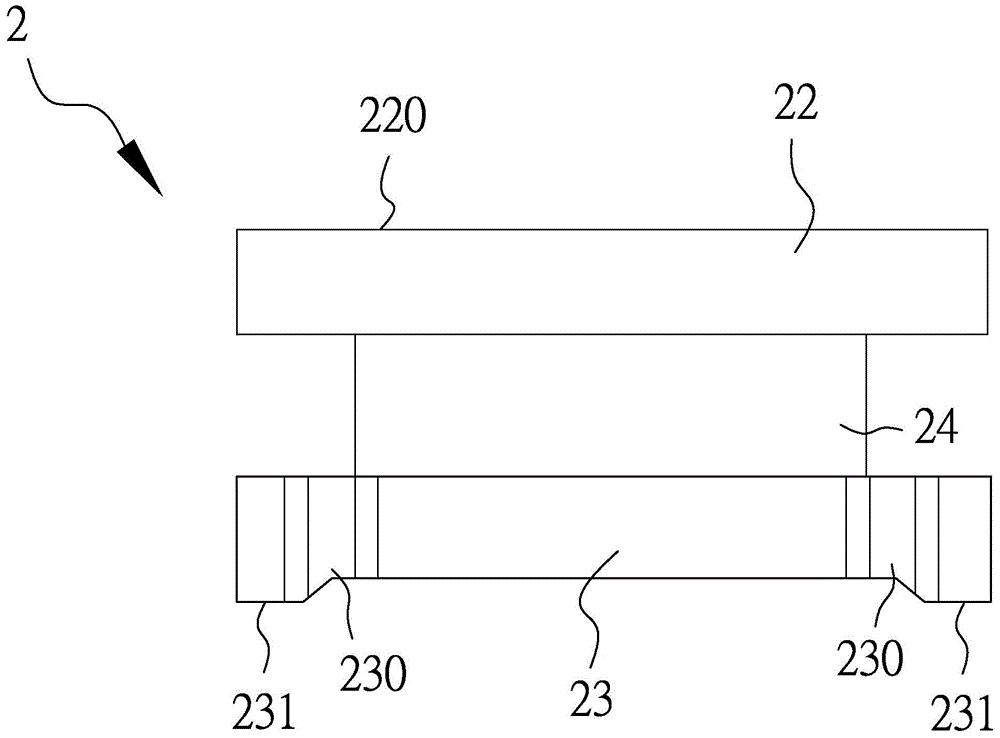

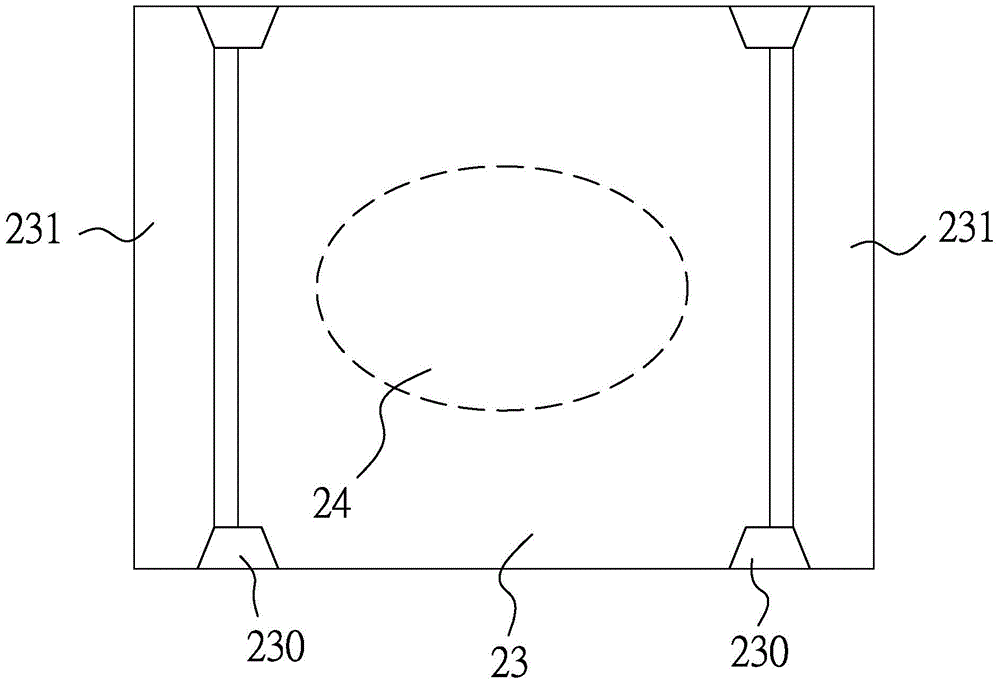

[0030] Magnetic core of the present invention, chip inductor with magnetic core and manufacturing method thereof, the magnetic core of the first preferred embodiment of the present invention is as Figure 1 to Figure 3 As shown, make as Figure 1-3 The shown magnetic core 2, the magnetic core 2 is composed of non-conductive ferromagnetic material such as ferric oxide, and the side view is like a letter I. The basic structure includes a top 22, a base 23, and a depression connecting the top 22 and the base 23 Winding part 24. Among them such as image 3 As shown in the perspective view of the bottom, the outlines of the top 22 and the base 23 are larger than the outline of the concave winding portion 24 (broken oval line). The uppermost surface of the top 22 is an adsorption plane 220 , which is used to facilitate the adsorption and movement of the suction nozzle of the mechanical arm when the inductance element is finally formed and surface-mounted to the circuit board.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com