Halogen-free flame retardant insulated power cable adopting polyphenyl ether composite material

A technology of power cables and composite materials, which is applied to insulated cables, power cables with shielding/conductive layers, and insulated conductors, etc., can solve the problems of safety, reliability and low service life, and achieve the effect of enhancing the safety of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

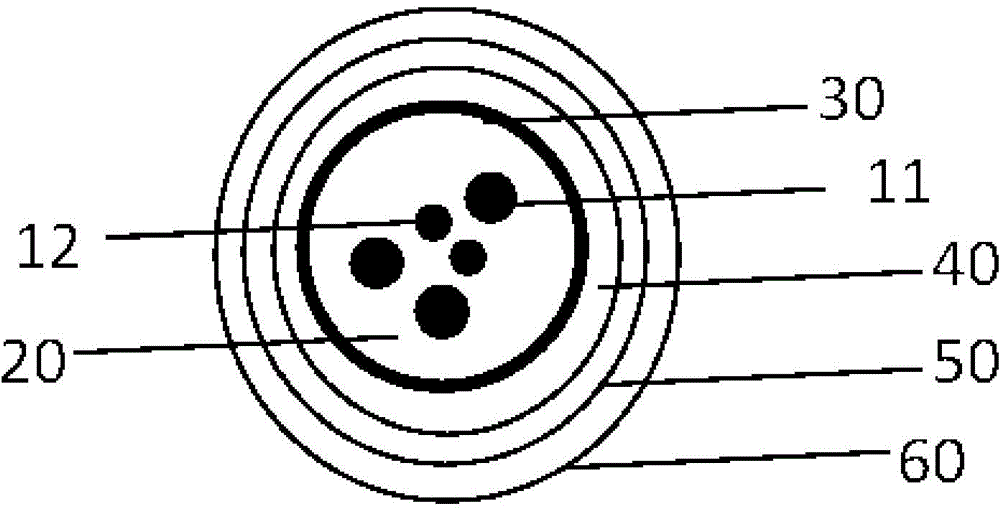

[0026] Such as figure 1 As shown, the halogen-free flame-retardant power cable described in this embodiment has an outer diameter of 16.9-75 mm, and includes multiple strands of insulated wire cores. The insulated wire cores have a 3+2 core structure, and the insulated wire cores are made of soft The copper conductive wire core made of copper wires and the coated polyphenylene ether composite material halogen-free flame-retardant filling material 20 are formed, in which the cross-sectional area of the conductors of the three main cores 11 is 4-240mm2, and the conductors of the two sub-cores 12 The cross-sectional area is 2.5-120mm2.

[0027] The insulated wire cores are filled with a halogen-free flame-retardant filling material 20 made of polyphenylene ether composite material, and covered with a water-blocking tape 30, and the outside of the water-blocking tape 30 is an aluminum-plastic composite tape 40, A shielding layer 50 is used outside the aluminum-plastic composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com