All-solid-state inorganic electrochromic device and its preparation method

An electrochromic device and electrochromic layer technology, which can be used in instruments, nonlinear optics, optics, etc., can solve the problems of poor thermal stability of polymer electrolytes, poor corrosion resistance of liquid electrolytes, and unfavorable large-scale production. Achieve large-scale production, the production method is simple and easy, and the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

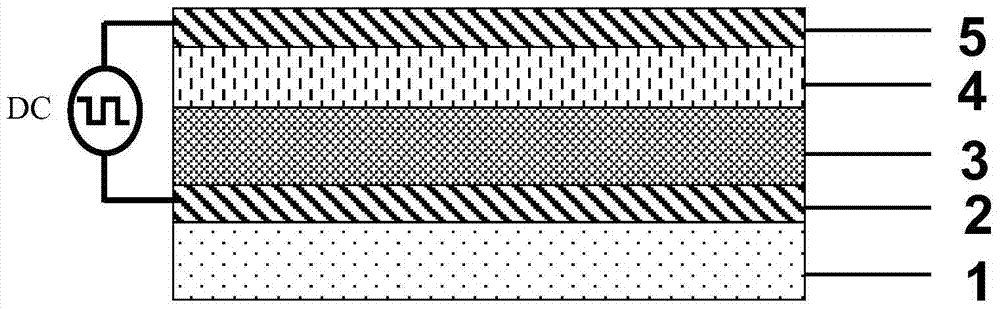

[0026] Such as figure 1 As shown, the present embodiment provides a single-layer all-solid-state inorganic electrochromic device. The transparent substrate 1 is an ordinary glass sheet; the first transparent conductive layer 2 is an indium zinc oxide (IZO) film, which communicates with an external power source as a cathode electrode; the first electrochromic layer 3 is tungsten oxide (WO x ) film, as the cathodic color change layer; electrolyte layer 4 is silicon dioxide (SiO 2 ) a transparent nanoparticle film as an electrolyte layer; the second transparent conductive layer 5 is an indium zinc oxide film, which is connected to an external power source and serves as an anode electrode.

[0027] The manufacturing method of the above-mentioned all-solid-state inorganic electrochromic device includes the following steps:

[0028] Step 1: The area cleaned by ultrasonic cleaning with acetone and absolute ethanol solution is 2.5×2.5cm 2 Ordinary glass is used as the transparent s...

Embodiment 2

[0035] Such as figure 2 As shown, the present embodiment provides a double-layer all-solid-state inorganic electrochromic device, the transparent substrate 1 is an ordinary glass sheet; the first transparent conductive layer 2 is an indium tin oxide (ITO) film, as a cathode electrode; The chromic layer 3 is tungsten oxide (WO x ) film, as a cathodic color change layer; electrolyte layer 4 is phosphorus-doped silicon dioxide (SiO 2 : P) film, as an electrolyte layer; the second transparent conductive layer 5 is an indium tin oxide (ITO) film, as an anode electrode; the second electrochromic layer 6 is a nickel oxide (NiO) film, as an anode color-changing layer.

[0036] The manufacturing method of the above-mentioned inorganic electrochromic device comprises the following steps:

[0037] Step 1: The area cleaned by ultrasonic cleaning with acetone and absolute ethanol solution is 2.5×2.5cm 2 Ordinary glass as a transparent substrate 1;

[0038] Step 2: Deposit a layer of i...

Embodiment 3

[0045] This embodiment provides a single-layer all-solid-state inorganic electrochromic device, the transparent substrate is an ordinary glass sheet; the first transparent conductive layer is an indium zinc oxide (IZO) film, which is connected with an external power source and serves as a cathode electrode; The chromic layer is tungsten oxide (WO x ) film as the cathodic color change layer; the electrolyte layer is perchloric acid (HClO 4 ) solution soaked silicon dioxide (SiO 2 ) film as an electrolyte layer; the second transparent conductive layer is an indium zinc oxide film, which communicates with an external power source and serves as an anode electrode.

[0046] The manufacturing method of the above-mentioned inorganic electrochromic device comprises the following steps:

[0047] Step 1: The area cleaned by ultrasonic cleaning with acetone and absolute ethanol solution is 2.5×2.5cm 2 ordinary glass as a transparent substrate;

[0048] Step 2: Deposit a layer of indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

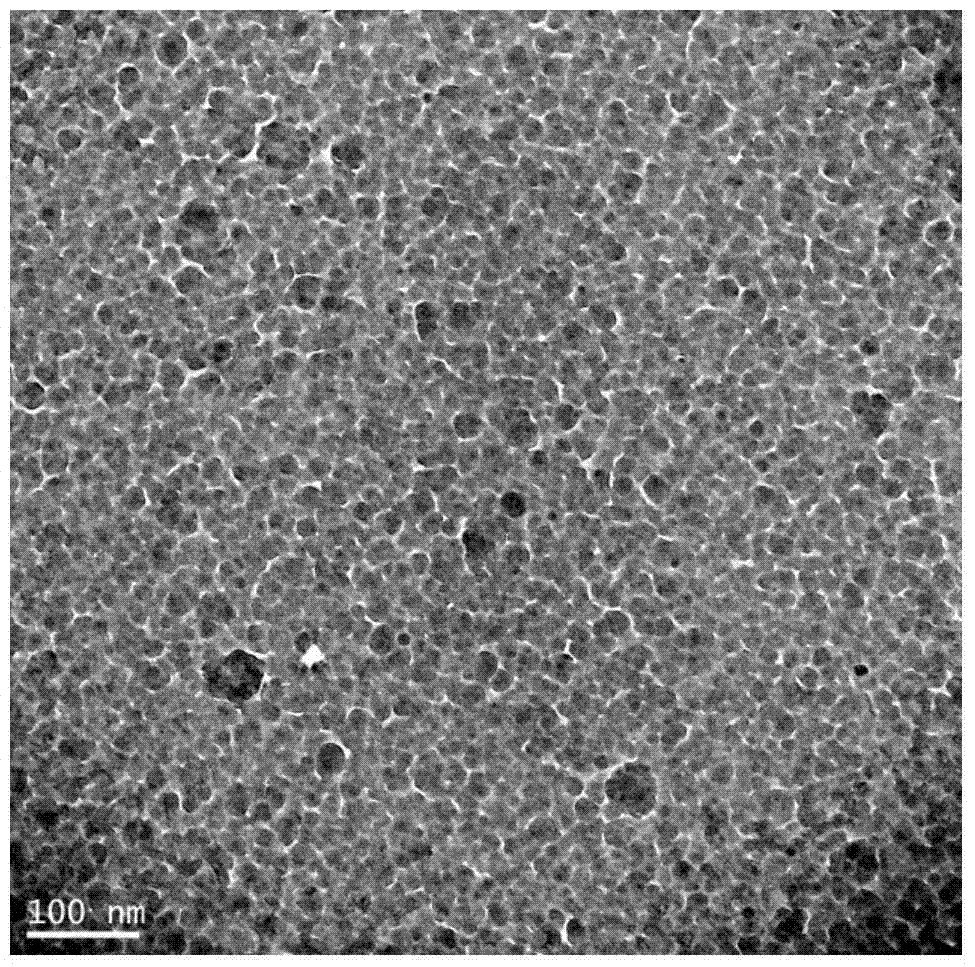

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com