Gauss laser beam shaping method and device and precise laser micropore processing device

A shaping device and micro-hole processing technology, which is applied in the field of laser applications, can solve the problems of taper, rough hole edge, and breakdown of the bottom of the hole, so as to improve utilization rate and processing efficiency, avoid bottom damage, and reduce energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

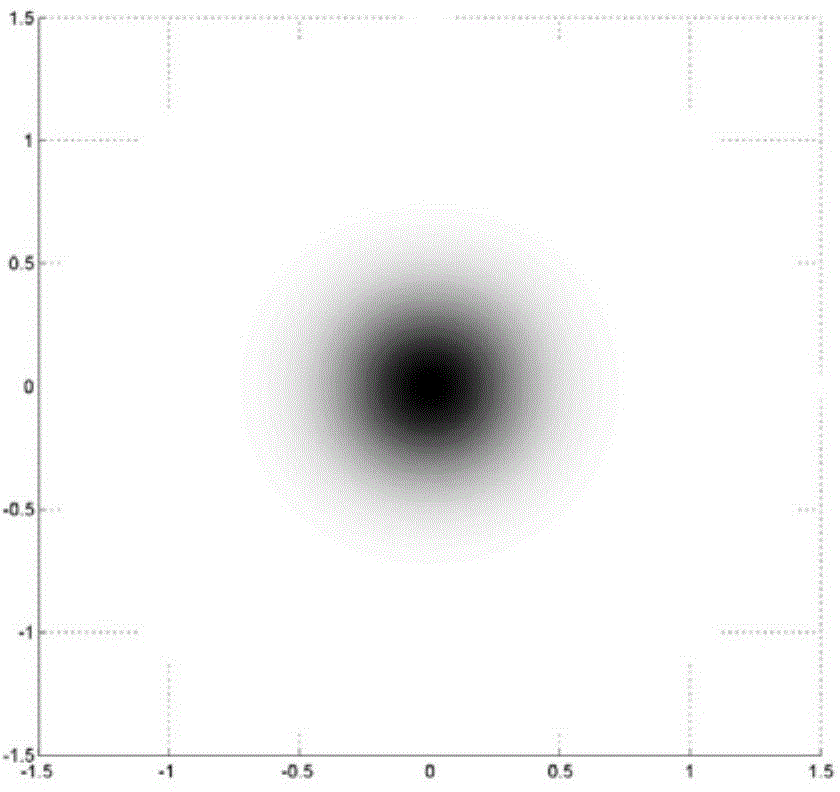

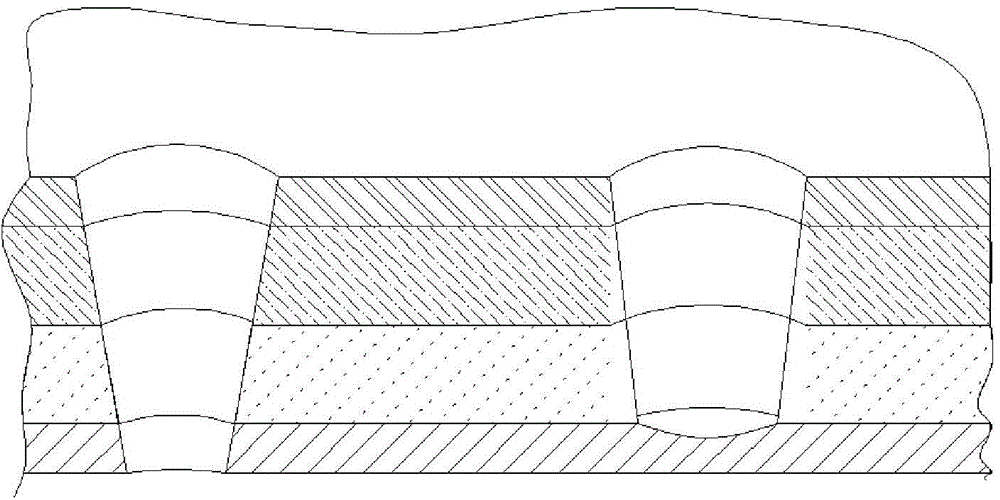

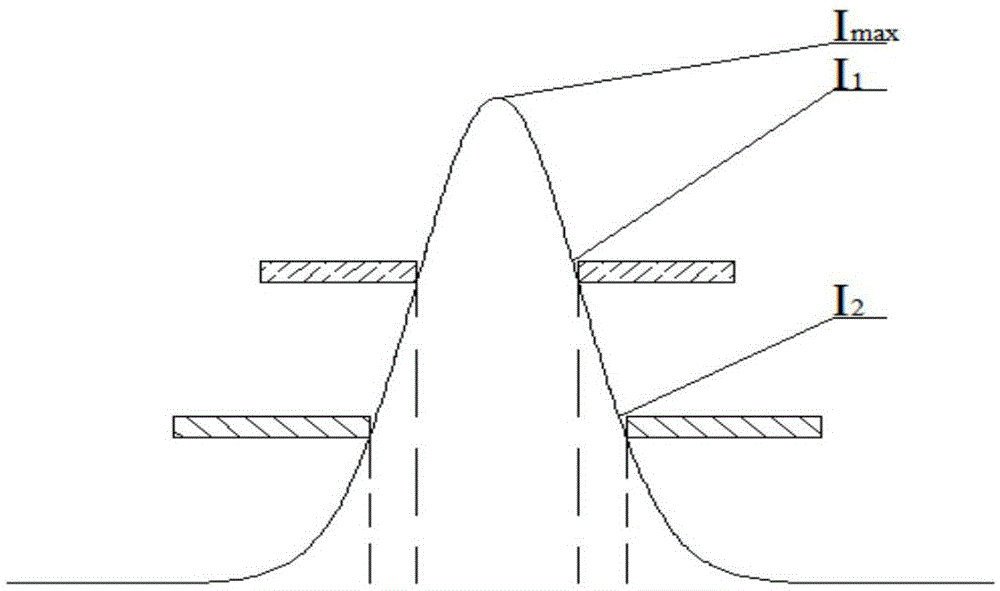

[0036] Such as Figure 4 , 5 As shown, the present invention provides a Gaussian laser beam shaping method, which includes first expanding the Gaussian laser beam emitted by the laser, then shaping the expanded Gaussian laser beam into a flat-topped laser beam, and then flattening the flattened laser beam. The laser beams are initially converged and then collimated to obtain a flat-topped laser beam output in parallel; finally, the flat-topped laser beams output in parallel are focused to obtain Figure 5Shown is a flat-hat laser beam ready for production processing. Further, in order to further improve the edge of the flat-hat laser beam, before the preliminary convergence of the flat-hat laser beam, a small hole diaphragm can be set on the focal plane of the flat-hat laser beam, The flat-hat laser beam is intercepted to reduce the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com