Magnetic material curie temperature measuring method based on thermogravimetry changes

A magnetic material, Curie temperature technology, applied in thermometers, thermometers, measuring devices and other directions using directly sensitive electrical/magnetic components, can solve the problems of high cost, unstable external magnetic field, complex structure, etc., to achieve economical Convenience, avoid the problem of coil heating, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

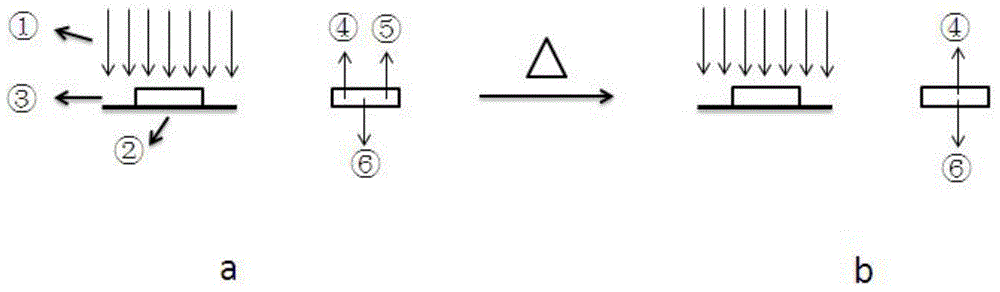

Method used

Image

Examples

Embodiment Construction

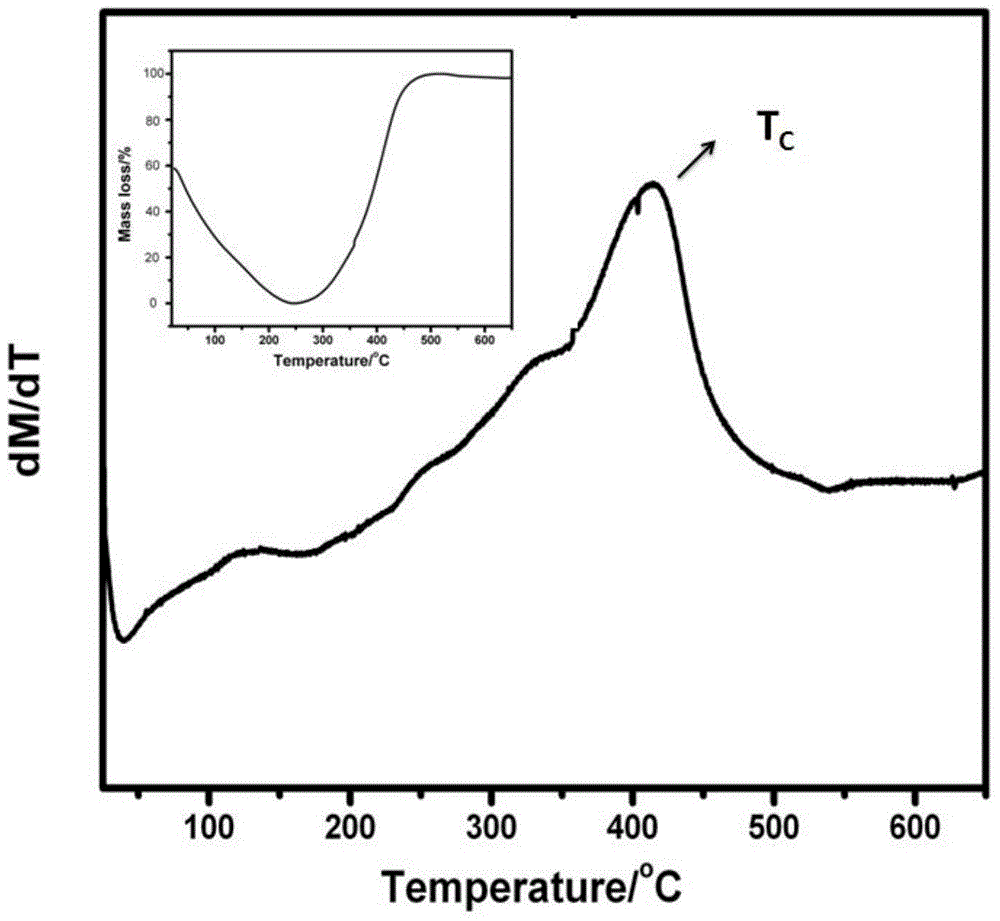

[0028] Below by measuring CoFe 2 o 4 The Curie temperature of the particles specifically describes the process of the invention. Specific steps are as follows:

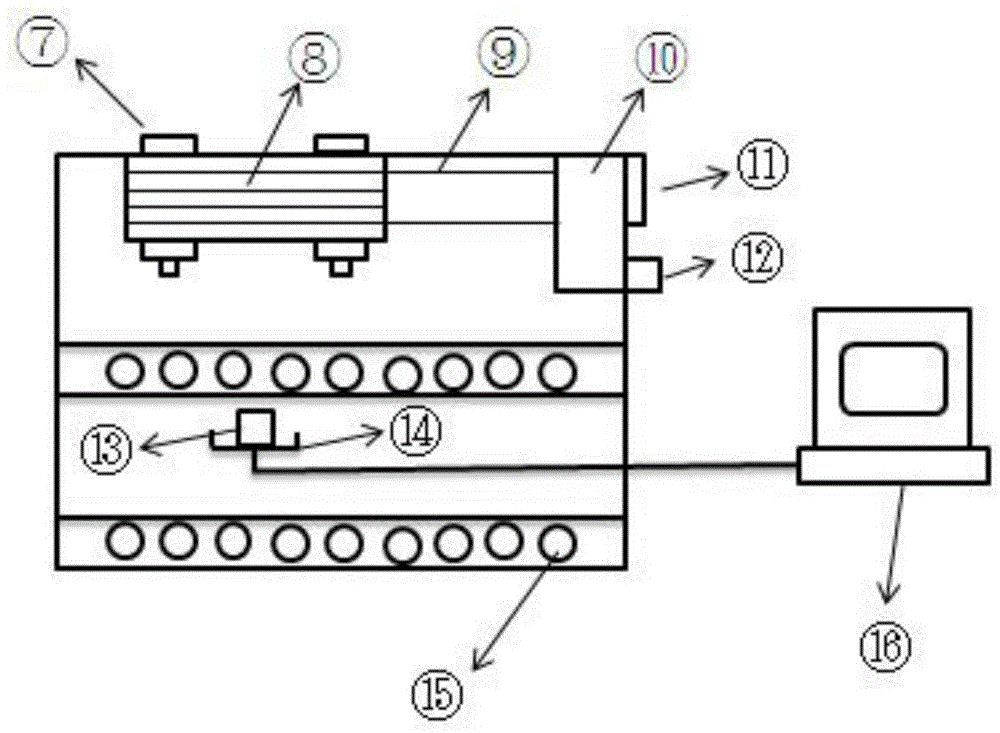

[0029] (1) Utilizing four carbon steel bolts 7 of M5 above the cooling system 15 of the thermogravimetric analyzer

[0030] Fixing a volume is 5cm * 5cm * 1cm, pure iron iron core 8, is covered with 8 turn insulated copper coils 9 on the pure iron core, forms electromagnet. Connected to both ends of the electromagnet coil 9 is a circuit control system 10, which consists of an AC-to-DC regulated power supply (220V to 12V), a fuse (rated current 2A, fusing current 3A), an ammeter and a resistance box (about 0-10kΩ) formed in series. Wherein, the current surface plate 11 and the resistance box knob 12 are all inlaid on the side of the thermogravimetric analyzer for convenient adjustment.

[0031] (2) Weigh about 36mg of CoFe 2 o 4 The sample is placed in the alumina crucible 13, and then placed together on the bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com