Totally-enclosed flue gas circulation system of straw gasification stove

A technology of circulation system and gasification furnace, which is applied in household appliances, household stoves/stoves, and stoves/stoves with hot water devices, etc., which can solve the problems of smoke and dust emission, environmental pollution, etc., improve thermal efficiency and increase heating area , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

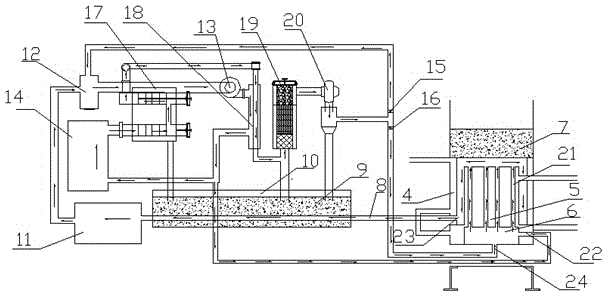

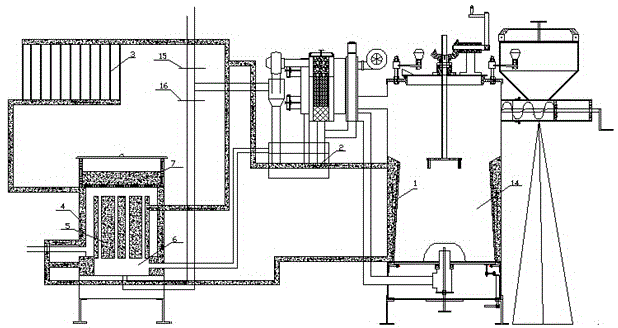

[0016] Embodiment 1, with reference to figure 1 , a fully enclosed flue gas circulation system for a straw gasification stove, comprising a straw gasification stove 14, a water jacket 1 is provided on the furnace body of the straw gasification stove 14, the water jacket 1 and a heating device 3 Connected; the gas outlet of the straw gasification stove 14 is connected to the tar treatment device 17 in turn, sealed through the air cooling device 18, connected to the filter device 19 and the phoenix induction device 20, and then enters the combustion chamber 6 of the combustion device. The flue gas circulation system includes two closed circulation systems, one is the closed circulation system of the flue gas generated when the straw gasification stove is started, and the other is the closed circulation system of the flue gas generated by the combustion of the combustion device; the smoke generated by the combustion of the combustion device The closed circulation system of gas is...

Embodiment 2

[0019] Embodiment 2, a fully enclosed flue gas circulation system of a straw gasification furnace, the furnace core 5 is evenly distributed with ventilation pipes 21, through which the upper and lower parts of the furnace chamber of the combustion device are connected. The rest are the same as embodiment 1. When the flue gas generated by the combustion of fuel gas in the combustion chamber 6 of the combustion device (stove) rises to the space between its upper part and the top of the furnace chamber through the ventilation pipes 21 in the furnace core 5, the upward flue gas is The space is blocked so that the flue gas cannot go upwards, and then descends to the flue gas outlet 23 at the bottom of the return water jacket 4 through the space formed by the outer wall of the furnace core 5 and the inner wall of the return water jacket 4 for recycling. The evenly distributed ventilation pipes 21 in the furnace core 5 enable the high-temperature flue gas to quickly and evenly heat t...

Embodiment 3

[0020] Example 3, a fully enclosed flue gas circulation system of a straw gasification stove, the water jacket 1 on the furnace body of the straw gasification stove is connected to a heating device 3, and the outlet of the heating device 3 is connected to a two-way water circulation system One way is for the outlet of the heating device 3 to be in sealing communication with the water jacket 4 on the furnace body of the combustion device, and the outlet of the water jacket 4 is in sealing communication with the water jacket 1 on the furnace body of the straw gasification furnace; the other is for the heating device 3 The outlet of the furnace core 5 is sealed and communicated with the water jacket 4 on the furnace body of the combustion device, and the water jacket 4 is sealed and communicated with the furnace core 5 in the furnace chamber of the combustion device. The above two return water circulation systems form a complementary hot water heating system and make full use of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com