Multistage fracturing tool pipe column of continuous oil pipe and construction method

A tool pipe and oil pipe technology, applied in the field of oil and gas field construction, can solve the problems of low construction efficiency, sand production in the formation, long construction period, etc., and achieve the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

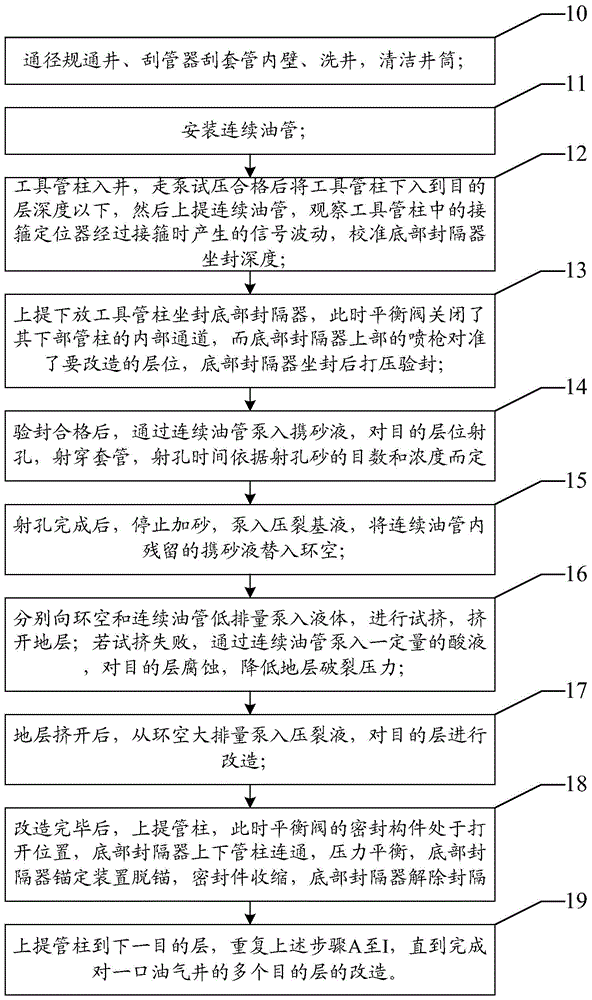

[0037] The first core of the present invention is to disclose a coiled tubing multi-stage fracturing tool string to achieve the purpose of shortening the time of fracturing acidification; the second core of the present invention is to disclose a coiled tubing multi-stage fracturing tool string Construction method. Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

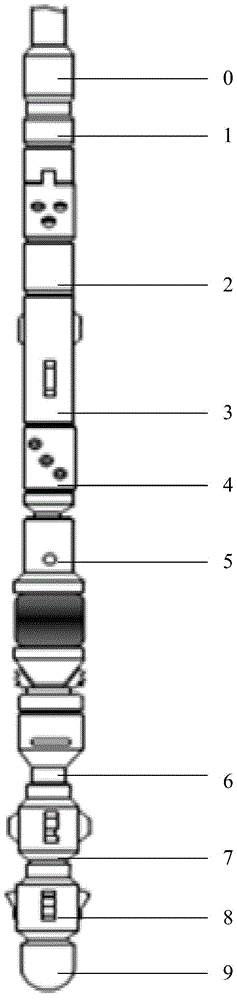

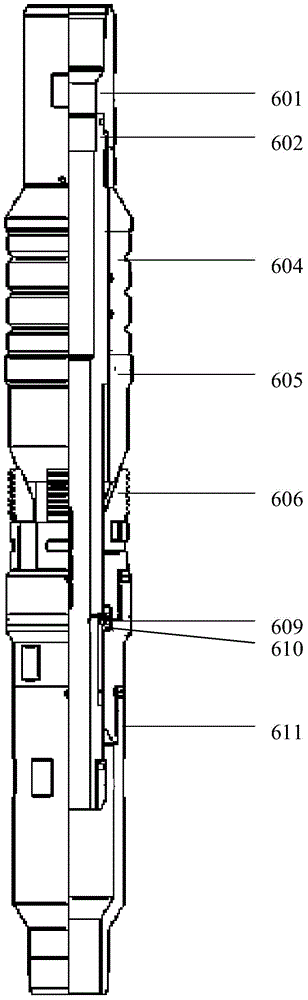

[0038] Such as figure 1 with figure 2 As shown, the coiled tubing multi-stage fracturing tool string includes a joint 1, a hand 2, a centralizer 3, a spray gun 4, a balance valve 5, a bottom packer 6, a friction nipple 7, a collar positioner 8 and a pilot Shoe 9, wherein, connecting hand 1, throw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com