A rotary grouting anchor cable drill body and construction technology of rotary grouting anchor cable

A technology of anchor cable and drill body, which is applied in the direction of liquid/gas jet drilling, drill bit, drill pipe, etc., which can solve the problems of slow construction speed and high requirements for construction operation conditions, and achieve reasonable cost, reduce surrounding disturbance, and high practicality value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

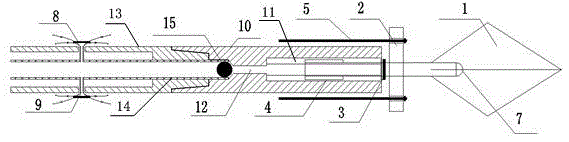

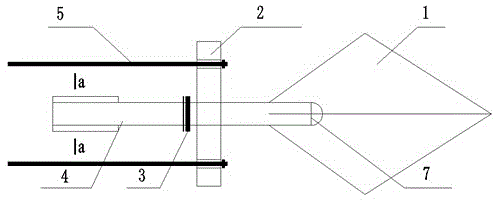

[0033] Such as figure 1 The rotary grouting anchor cable drill body shown is composed of a double-pipe rotary grouting drill pipe, a variable-diameter linkage slotted drill pipe, an anchor head and a back-sealing steel ball. The rear end of the double-pipe rotary grouting drill pipe is connected to the front end of the variable-diameter linkage slot drill pipe, and the rear end of the variable-diameter linkage slot drill pipe is connected to the anchor head. The connection of grooved drill rods.

[0034] The double-pipe rotary jet drill pipe includes the rotary jet hole 9, the rotary jet drill pipe 13 and the inner pipe 14. The drill pipe 13 passes through, and the rotary nozzle hole 9 is a through hole penetrating through the rotary nozzle drill pipe 13 and the inner pipe 14; , the front end of the linkage slot drill rod 10 is provided with an inner hole, the inner hole is an inner hole that can match the rear end of the rotary jet drill rod 13, and the rear end of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com