Preparation method of gradient composite anode for nonferrous metals electrodeposition

A composite anode, non-ferrous metal technology, applied in the field of electrochemistry, can solve the problems of the deposition layer and the surface of the electrode are not tightly combined, the deposition layer is easy to peel off, the deposition layer is uneven, etc., to reduce cracks, improve service life, and increase the amount of deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

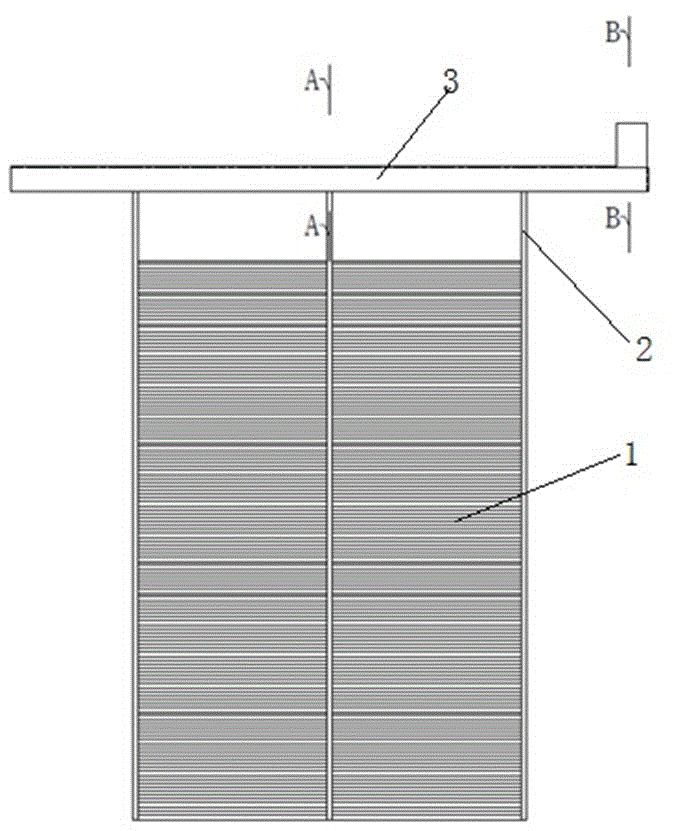

[0029] Example 1: A method for preparing a gradient composite anode for non-ferrous metal electrowinning, the method is carried out in the following steps:

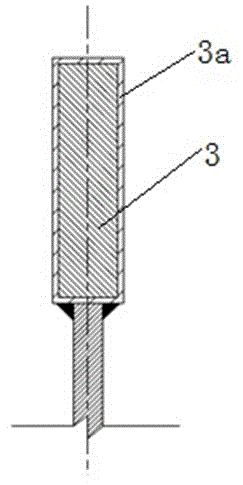

[0030] The titanium rod 1 is prepared by the drawing and extrusion process, and a group of horizontal titanium rods are connected with three titanium-copper-clad vertical rods 2 to assemble as shown in FIG. figure 1 For the fence-type titanium plate substrate shown, put the substrate into boiling sodium hydroxide solution with a mass volume ratio of 10% and boil for 0.5h, rinse with water, and put in HCl:HF:HNO 3 Soak in a mixed acid solution with a volume ratio of 5:1:2 for 3 to 5 minutes, rinse with water, boil in a 20% HCl solution for 0.5 hours, wash with deionized water, dry with hot air, and set aside; titanium The rod is a round heterogeneous toothed cylindrical titanium rod, and its cross-sectional shape is as follows Figure 4For the circular heterogeneous tooth type shown, the maximum outer diameter, that i...

Embodiment 2

[0035] Example 2: A method for preparing a gradient composite anode for electrowinning of nonferrous metals, the specific operations are as follows:

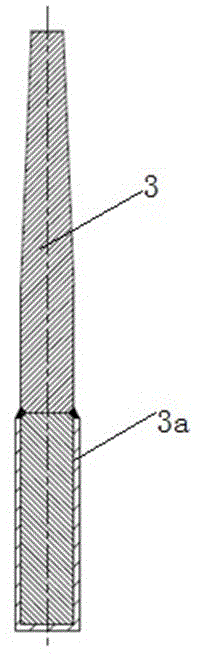

[0036] The titanium rod 1 is prepared by the drawing and extrusion process, and a group of horizontal titanium rods are connected with three titanium-copper-clad vertical rods 2 to assemble as shown in FIG. figure 1 For the fence-type titanium plate substrate shown, put the substrate into boiling sodium hydroxide solution with a mass volume ratio of 10% and boil for 0.5h, rinse with water, and put in HCl:HF:HNO 3 Soak in a mixed acid solution with a volume ratio of 5:1:2 for 3 to 5 minutes, rinse with water, boil in a 20% HCl solution for 0.5 hours, wash with deionized water, dry with hot air, and set aside; titanium The rod is a round heterogeneous toothed cylindrical titanium rod, and its cross-sectional shape is as follows Figure 5 For the elliptical heterogeneous tooth type shown, the maximum outer diameter, that is, t...

Embodiment 3

[0041] Example 3: A method for preparing a gradient composite anode for non-ferrous metal electrowinning, the specific method is as follows:

[0042] The titanium rod 1 is prepared by the drawing and extrusion process, and a group of horizontal titanium rods are connected with three titanium-copper-clad vertical rods 2 to assemble as shown in FIG. figure 1 For the fence-type titanium plate substrate shown, put the substrate into boiling sodium hydroxide solution with a mass volume ratio of 10% and boil for 0.5h, rinse with water, and put in HCl:HF:HNO 3 Soak in a mixed acid solution with a volume ratio of 5:1:2 for 3 to 4 minutes, then rinse with water and boil in a 20% HCl solution for 0.5 hours, wash with deionized water, dry with hot air, and set aside; titanium The rod is a round zigzag cylindrical titanium rod, and its cross-sectional shape is as follows: Image 6 The circular sawtooth shape shown, the maximum outer diameter of the titanium rod is 12mm, and the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com