High-homogeneous large-size ultrahigh-strength steel bar and production method thereof

A technology of ultra-high strength and production method, applied in the field of ultra-high strength steel, to achieve the effect of reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

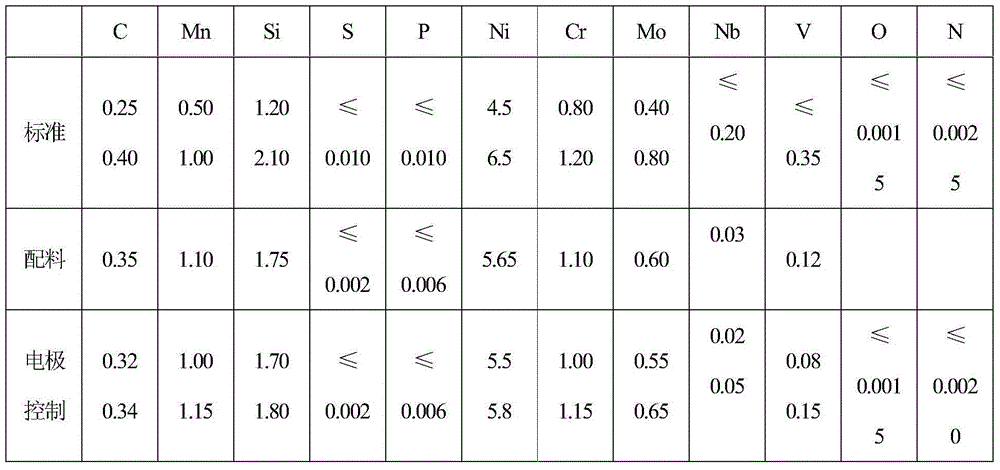

Method used

Image

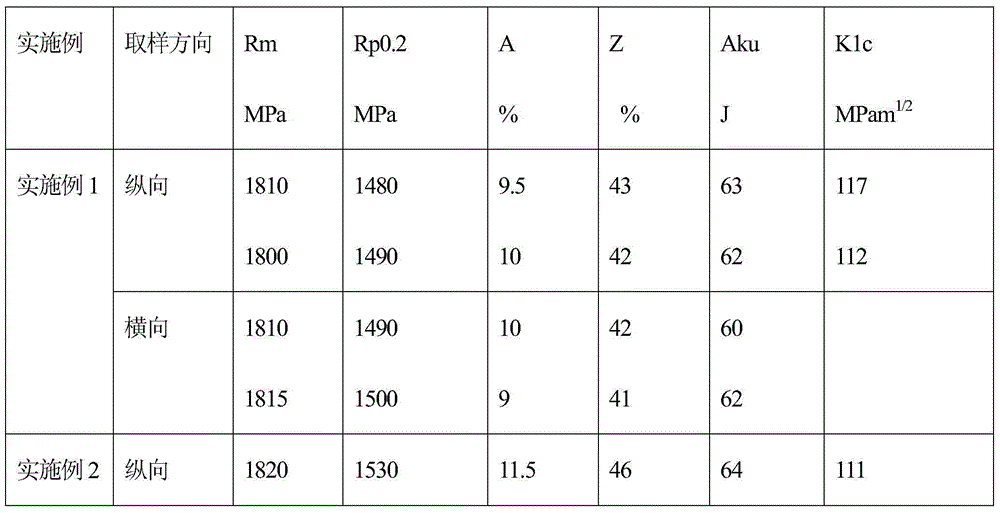

Examples

Embodiment 1

[0050] (1) VIM smelting is fully stirred, ∮720mm electrode (steel ingot) is poured at 1530°C, the electrode is kept at 650°C±10°C for 20 hours, furnace cooled to 500°C, air-cooled and annealed, then polished. The electrode is remelted in a vacuum consumable furnace to ∮810mm×2650mm steel ingot, and the steel ingot is annealed at 650℃~670℃ for 30 hours and then polished to ∮800mm×2650mm (height-to-diameter ratio 3.3).

[0051] (2) forging

[0052] Steel ingot heating: Furnace loading temperature: 650°C; steel ingot heating rate: 100°C / hour, the temperature rises to 800°C for 3 hours, and the steel ingot continues to heat up, heating rate: 90°C / hour, when the temperature reaches 1220°C, the steel ingot is out of the furnace Forging ∮ 350mm*450mm pliers, the ingot is kept in the heating furnace for 2 hours, turned over 90 degrees, and the ingot is returned to the furnace for 2 hours for forging.

[0053] One-time upsetting and drawing: place the steel ingot with pliers on a circ...

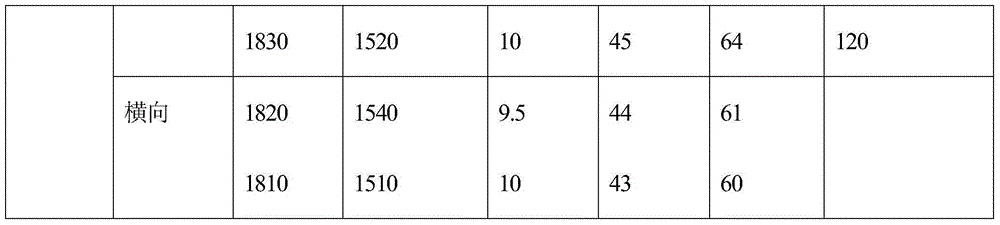

Embodiment 2

[0058] (1) VIM smelting is fully stirred, ∮720mm electrode (steel ingot) is poured at 1550°C, the electrode is kept at 650°C±10°C for 20 hours, furnace cooled to 500°C, air-cooled and annealed, then polished. The electrodes are remelted in a vacuum consumable furnace with a ∮810mm×2650mm (height-to-diameter ratio 3.3) steel ingot, and the steel ingot is annealed at 650°C to 670°C for 30 hours and then polished.

[0059] (2) forging

[0060] Steel ingot heating: Furnace loading temperature: 650°C; steel ingot heating rate: 90°C / hour, the temperature rises to 800°C for 3.5 hours and then the steel ingot continues to heat up, heating rate: 90°C / hour, when the temperature reaches 1230°C, the steel ingot is out of the furnace Forging ∮ 350mm*450mm pliers, the steel ingot is kept in the heating furnace for 3 hours and turned over 180 degrees. The ingot is returned to the furnace and kept for 1 hour for forging.

[0061] One-time upsetting and drawing: place the steel ingot with pli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com