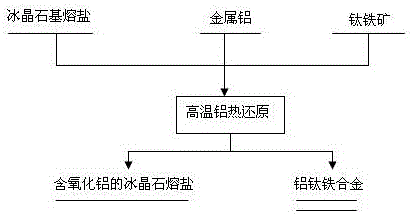

A kind of method for preparing al-ti-fe alloy by thermite reduction of ilmenite in cryolite-based molten salt

A technology of ilmenite and al-ti-fe, which is applied in the field of thermite reduction of ilmenite to prepare Al-Ti-Fe alloy, can solve the problems of low current efficiency, impure electrolytic products, increased production cost and energy consumption, etc. , to achieve good effect, fast reduction reaction rate, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Using metal aluminum as the reducing agent, the ilmenite is subjected to thermite reduction in a cryolite-based molten salt medium at 930°C for 2 hours. The composition of ilmenite is: 41.70%TiO 2 , 30.24% FeO, 10.63% Fe 2 o 3 , 1.50% CaO, 1.89% MgO, 9.99% SiO 2 , 3.18% Al 2 o 3, and the rest is impurities. After the reaction, the alloy and molten salt are separated to obtain Al-Ti-Fe alloy and Al-rich 2 o 3 The cryolite-based molten salt, the Al-Ti-Fe alloy contains 83.55% Al, 15.15% Ti, 0.41% Fe, and 0.89% Si by mass percentage;

[0031] Among them, the rich Al 2 o 3 The cryolite-based molten salt is electrolyzed at 930 ° C, with Fe-Ni alloy as the anode, aluminum liquid as the cathode, and the current density of the cathode and anode in the electrolysis process is controlled at 0.4A / cm 2 , Metal aluminum is obtained at the cathode, the mass purity of Al in metal aluminum is 95.07%, contains Ti 1.93%, Fe 1.86%, and oxygen is obtained at the anode.

[0032] Th...

Embodiment 2

[0036] Using metal aluminum as the reducing agent, ilmenite was subjected to thermite reduction in cryolite-based molten salt medium at 955°C for 2 hours, and the composition of ilmenite was: 48.68%TiO by mass percentage 2 , 36.78% FeO, 10.97% Fe 2 o 3 , 0.05% CaO, 1.18% MgO, 0.67% SiO 2 , 0.60% Al 2 o 3 , and the rest is impurities. After the reaction, the alloy and molten salt are separated to obtain Al-Ti-Fe alloy and Al-rich 2 o 3 The cryolite-based molten salt, the Al-Ti-Fe alloy contains 79.25% Al, 18.78% Ti, 1.05% Fe, and 0.92% Si by mass percentage;

[0037] Among them, the rich Al 2 o 3 The cryolite-based molten salt was electrolyzed at 955°C to Fe-Ni-Al 2 o 3 The cermet is the anode, the aluminum liquid is the cathode, and the cathode and anode current densities of the electrolysis process are controlled at 0.6A / cm 2 , Metal aluminum is obtained at the cathode, the mass purity of Al in metal aluminum is 95.78%, contains Ti 2.11%, Fe 1.07%, and oxygen is obt...

Embodiment 3

[0042] Using metal aluminum as a reducing agent, ilmenite was subjected to thermite reduction in a cryolite-based molten salt medium at 965°C for 2 hours. The composition of ilmenite was: 49.85%TiO by mass percentage 2 , 35.50% FeO, 9.58% Fe 2 o 3 , 0.24% CaO, 1.99% MgO, 0.86% SiO 2 , 0.23% Al 2 o 3 , and the rest is impurities. After the reaction, the alloy and molten salt are separated to obtain Al-Ti-Fe alloy and Al-rich 2 o 3 The cryolite-based molten salt, the Al-Ti-Fe alloy contains 81.05% Al, 16.20% Ti, 1.88% Fe, and 0.87% Si by mass percentage;

[0043] Among them, the rich Al 2 o 3 The cryolite-based molten salt is electrolyzed at 965°C, with Fe-Ni alloy as the anode and molten aluminum as the cathode, and the cathode and anode current densities of the electrolysis process are controlled at 0.8A / cm 2 , Metal aluminum is obtained at the cathode, the mass purity of Al in metal aluminum is 96.78%, contains Ti 1.21%, Fe 1.95%, and oxygen is obtained at the anode. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com