Flame-retardant polyester and producing method thereof

A flame-retardant polyester and a manufacturing method technology, applied in the field of flame-retardant polyester and its manufacturing, can solve the problems of high phosphorus content and high flame retardancy, decreased fiber melting point, hand feeling discount, etc., and achieve dry heat shrinkage rate. Excellent, excellent friction resistance, good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The ethylene glycol esterification solution of the flame retardant is prepared for use, and the flame retardant shown in formula 4 is mixed with ethylene glycol to prepare an esterification solution A with a phosphorus content of 5.8wt% and an acid value of 76mgKOH / g.

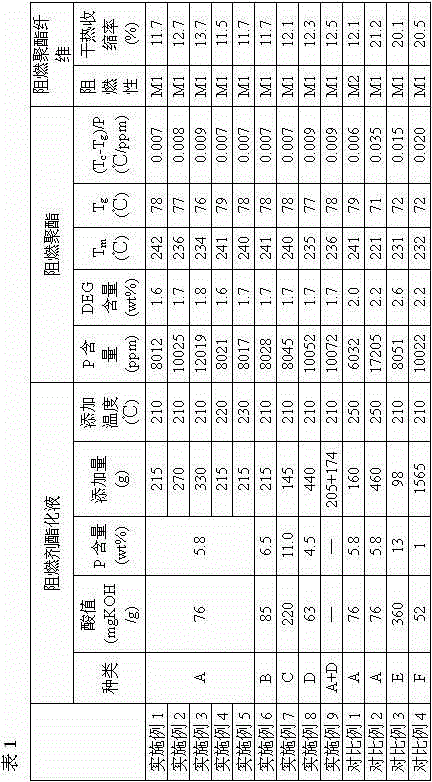

[0045] After esterifying 1150g of terephthalic acid and 530g of ethylene glycol, add 215g of the above-mentioned flame retardant esterification solution A before the polymerization reaction. The addition temperature is controlled at 210°C, and the flame retardant and polymerization catalyst B are added within 50 minutes. Antimony glycol and phosphorus compound stabilizers, the system reaches a full vacuum below 200Pa after 40 minutes, the polymerization start temperature is 210°C, and the final polymerization temperature is 285°C 120 minutes after the start of heating. In the finally obtained polyester, relative to the total amount of flame retardant polyester, the content of phosphorus element was 80...

Embodiment 2

[0048] Add 270g of esterification solution A before the polymerization, and the others are the same as in Example 1. The content of phosphorus in the obtained flame-retardant polyester is 10025ppm, and the content of DEG is 1.7wt%. Other results are shown in Table 1.

Embodiment 3

[0050] Add 330g of esterification solution A before the polymerization, and the others are the same as in Example 1. The phosphorus content in the obtained flame-retardant polyester is 12019ppm, and the DEG content is 1.8wt%. Other results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com