Preparation method of powdery cytidine triphosphate or sodium salt of cytidine triphosphate

A cytidine triphosphate, powdered technology is applied in the field of preparation of powdered cytidine triphosphate or its sodium salt, and can solve the problems of long refining time, manual grinding and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

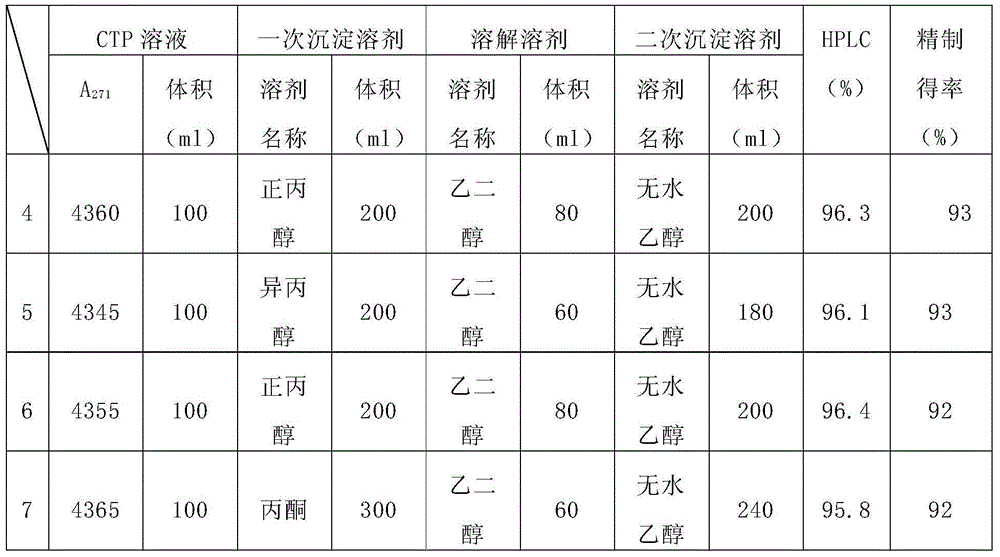

Examples

Embodiment approach

[0019] The first is to mix and precipitate an acidic solution containing cytidine triphosphate or its sodium salt with 5-20 times the volume of methanol to obtain powdered cytidine triphosphate or its sodium salt;

[0020] A second embodiment includes the steps of:

[0021] In the first step, the acidic solution containing cytidine triphosphate or its sodium salt is mixed with 2-20 times the volume of the first organic solvent to obtain the first precipitate;

[0022] In the second step, the first precipitate and 2-20 times the volume [volume of ethylene glycol or glycerol (ml): cytidine triphosphate or its sodium salt solution converted to pure weight (g) = 2-20 times] Ethylene glycol or glycerol mixed to obtain a solution;

[0023] In the third step, the solution is mixed with 2-20 times the volume of the second organic solvent and precipitated to obtain powdered cytidine triphosphate or its sodium salt.

[0024] The pH of the acidic solution containing cytidine triphospha...

Embodiment 1

[0046] Weigh 20g CTP, add 1mol / L NaCl solution to dissolve and dilute to 100ml, the resulting solution A 271 is 4300, and the pH is about 3.0. The above CTP solution was slowly added dropwise to 500ml of methanol, and a CTP precipitate was formed. After suction filtration, anhydrous ether was added to the filter cake to remove water, and suction filtration was performed again, and the final wet powder was vacuum-dried (pentoxide Diphosphorus is used as a desiccant, and the vacuum degree is -0.1Mpa).

[0047]The parameters of the CTP product obtained by the method of this embodiment: HPLC: 97.1%; refined quality yield: 96%.

Embodiment 2

[0049] Weigh 20g CTP, add 1mol / L NaCl solution to dissolve and dilute to 100ml, the resulting solution A 271 It is 4320, and the pH is about 3.0.

[0050] Primary precipitation: Add 300ml of 95% ethanol to the above CTP solution, leave it for more than 4 hours, and viscous precipitation will occur.

[0051] Secondary precipitation: dissolve the above precipitate with 40ml ethylene glycol, then slowly add the solution dropwise to 120ml absolute ethanol, and a CTP precipitate will form.

[0052] After suction filtration, add 40ml of absolute ethanol to the filter cake for washing, then suction filtration again, add anhydrous ether to the filter cake to remove moisture and suction filtration, and vacuum dry the final wet powder (phosphorus pentoxide is the desiccant, The vacuum is -0.1Mpa).

[0053] The parameters of the CTP product obtained by the method of this example: HPLC: 96.6%, and the refined mass yield: 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com