zrb with core-shell structure 2 ‑sic/si composite powder and preparation method thereof

A technology of composite powder and core-shell structure, which is applied in the coating and other directions, can solve the problems that the coating is difficult to meet the high-temperature thermal protection performance requirements, the two phases in the coating cannot be uniformly dispersed, and the SiC composition is insufficient, etc., to achieve large-scale production. Industrialized production, promoting the improvement of coating performance, and the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

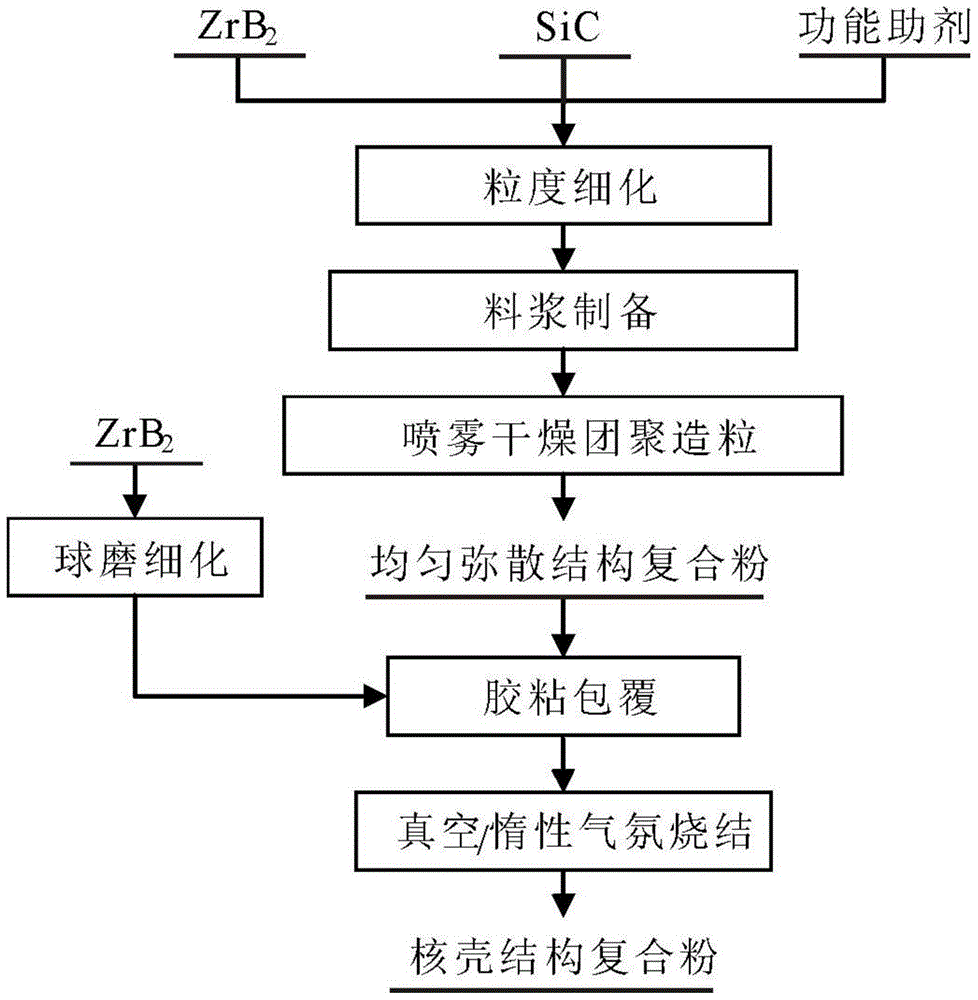

[0042] The present invention provides a kind of above-mentioned ZrB with core-shell structure 2 -The preparation method of SiC / Si composite powder, specifically comprises the following steps:

[0043] 1): The particle size refinement of each original powder:

[0044] After the powder is refined, the primary primary particle size of each primary powder is less than 5 μm;

[0045] 2): Powder spray drying agglomeration granulation:

[0046] The refined powder is weighed according to the mass percentage of the nucleus, and used as spray granulation;

[0047] The refined powder is mixed with an organic binder to form a slurry for ball milling, and then the slurry after ball milling is spray-dried and agglomerated in a spray drying tower. 60-100ml / min; the inlet temperature is between 250-350°C, the outlet temperature is between 100-220°C, and after spray drying, solid aggregate particles containing organic binders are obtained, namely ZrB 2 - SiC composite powder;

[0048] 3):...

Embodiment 1

[0067] In the core-shell structure composite powder prepared in this example: the shell is completely ZrB 2 , accounting for 15wt% of the total powder weight, ZrB in the inner core 2 and SiC composition percentages were 60wt% and 25wt%.

[0068] The core-shell structure ZrB in the present embodiment 2 Pack ZrB 2 -SiC homogeneously dispersed composite powder is prepared by the following method, including the following steps:

[0069] 1) The particle size refinement of each original powder:

[0070] Using ball milling process, in the ball mill, add ZrB respectively 2 , SiC, ZrO 2 Grinding balls and water, set the mass ratio of grinding balls: powder: ball milling medium water at 7.5:1:2.5, the ball milling speed is set to 300r / min, the ball milling time is 6h, and the ball milling is dried at 120°C for 10h in vacuum.

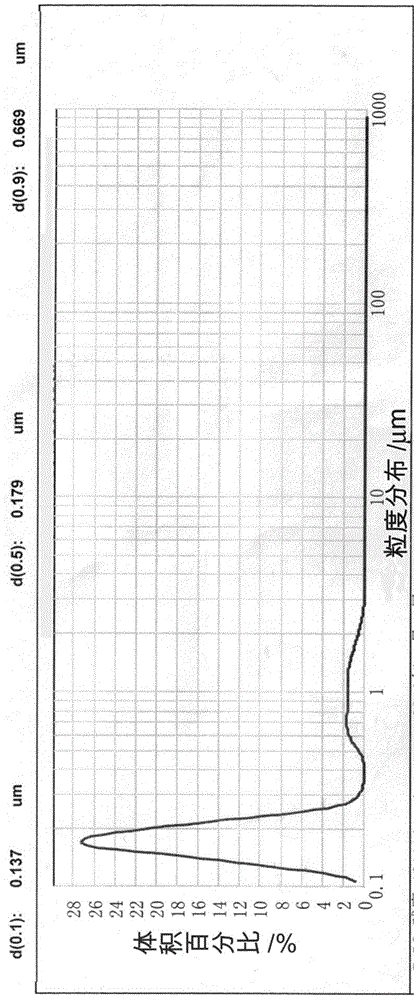

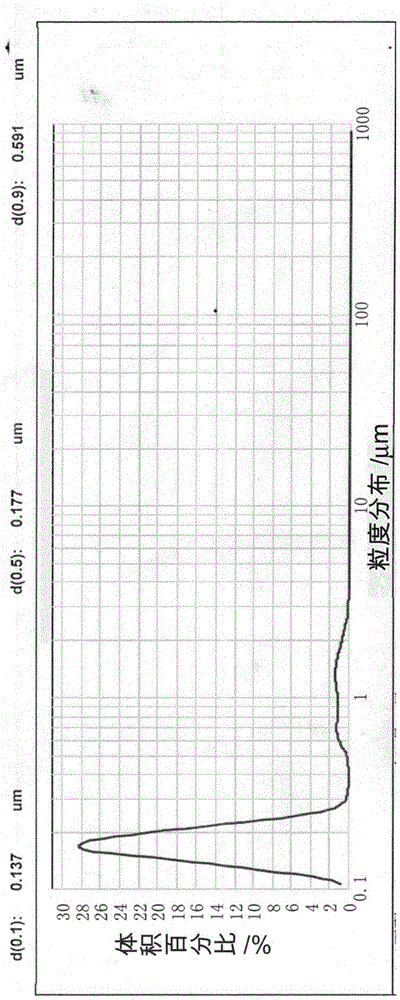

[0071] After ball milling and drying, ZrB 2 and the particle size distribution diagrams of SiC, respectively, as figure 2 and image 3 shown.

[0072] ...

Embodiment 2

[0082] The core-shell structure composite powder prepared in this example: the shell is completely ZrB 2, accounting for 15wt% of the total composition of the powder, ZrB in the core 2 and Si composition percentages were 77.3wt% and 7.7wt%.

[0083] The core-shell structure ZrB in the present embodiment 2 Pack ZrB 2 -Si homogeneously dispersed composite powder is prepared by the following method, including the following steps:

[0084] 1) The particle size refinement of each original powder:

[0085] Original ZrB 2 , Si, etc. are respectively added to the jet milling classifier and processed by jet milling method, the crushing pressure is: 0.8Mpa, and the airflow speed can reach supersonic speed 400m / s at this time.

[0086] 2) Spray drying and agglomeration granulation of powder:

[0087] Weigh the refined powder according to the required mass percentage of the nucleus. Spray granulation virgin powder ZrB 2 , Si and organic binder solution are mixed to form a slurry f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com