Ferrite composition and electronic component

一种电子部件、铁氧体的技术,应用在变压器/电感的零部件、电气元件、电路等方向,能够解决电感元件损耗易增加、Q值下降等问题,达到高Q值、Q值大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] First, as a raw material of the main component, Fe 2 o 3 , NiO, CuO, and then prepare ZnO in the presence of zinc oxide. Prepare SnO as a raw material for subcomponents 2 、 Bi 2 o 3 、Co 3 o 4 .

[0067] Next, the prepared raw material powders of the main component and the subcomponent were weighed so as to have the compositions described in Table 1 and Table 2 as sintered compacts, and wet-mixed with a ball mill for 16 hours to obtain a raw material mixture.

[0068] Next, after drying the obtained raw material mixture, it calcined in air at 720 degreeC for 4 hours, and turned it into the calcined powder. The calcined powder was subjected to wet pulverization for 16 hours using a ball mill made of steel to obtain a pulverized powder.

[0069] Next, after drying the pulverized powder, 10.0 wt % of a 6 wt % polyvinyl alcohol aqueous solution as a binder was added to 100 wt % of the pulverized powder and granulated to form granules. The pellets were press-molded t...

Embodiment 2

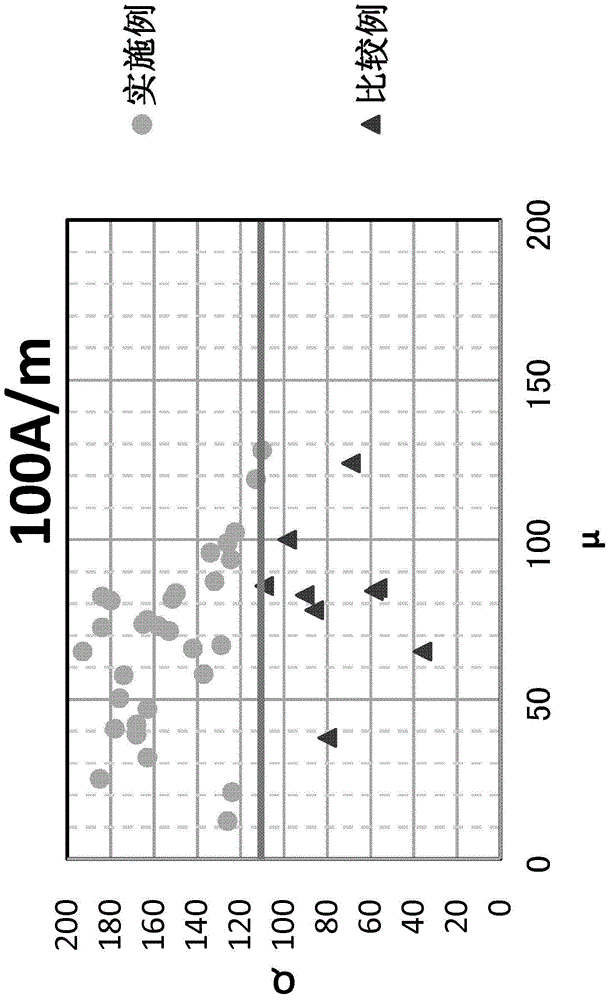

[0083] For sample No. 11 in Table 1 and sample Nos. 31, 32, and 33 in Table 2, the Q value was measured under an external magnetic field (H=20 to 400A / m) other than H=100A / m and 200A / m. The results are summarized in Figure 5 . Except for the external magnetic field, it was measured in the same manner as in Example 1. Note that sample No. 31 corresponds to a conventional non-additive material, sample No. 32 corresponds to a conventional Co-added material, and sample No. 33 corresponds to a conventional SnBi-added material. In addition, the Q value cannot be measured at H=350, 400 A / m in the conventional non-additive material and the Co-added material.

[0084] from Figure 5 It can be seen that the SnCoBi-added material according to the present invention can maintain a higher Q value under a high magnetic field of 20 to 400 A / m than conventional non-added materials, Co-added materials, and SnBi-added materials.

[0085] To sum up, it is possible to sinter the ferrite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com