High-efficiency oil removal and turbidity removal device and oil-containing and turbidity-containing wastewater treatment process

A high-efficiency, clarification device technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of small footprint, low operating cost, complex structure and operation, etc. , to achieve the effects of small footprint, reduced operating costs, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

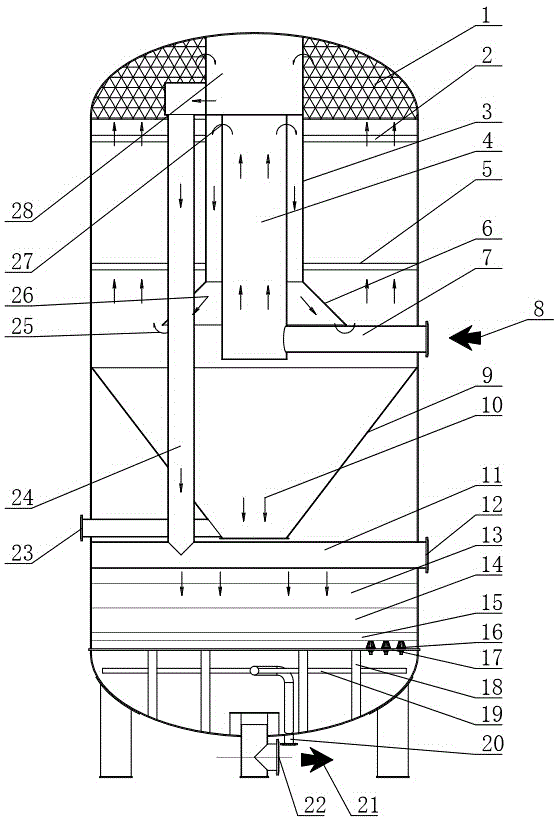

[0020] Such as figure 1 As shown, the high-efficiency oil and turbidity removal device of the present invention is an integrated tank structure. The upper part of the tank body is a water mixing reactor and clarification device, the middle part is a sludge collection and discharge device, and the lower part is a filter and backwashing system. The water inlet mixing reactor consists of a central pipe 4 and an outer casing 3 to form a double-layer pipeline. The bottom of the central pipe 4 is connected to the water inlet pipe 7, the upper part of the central pipe 4 is connected to the outer casing 3, and the bottom of the outer casing 3 is provided with a conical diffusion cover 6 ; The water inlet mixing reactor is fixed in the center of the tank through the fixed support 5 and the packing frame 2 . Filler 1 is arranged in the cavity on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com