Method for increasing methane production efficiency of continuous-flow anaerobic reactor by continuously adding Fe3O4 nanoparticles

An anaerobic reactor and nanoparticle technology, applied in chemical instruments and methods, anaerobic digestion treatment, water/sludge/sewage treatment, etc. Guaranteed efficient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

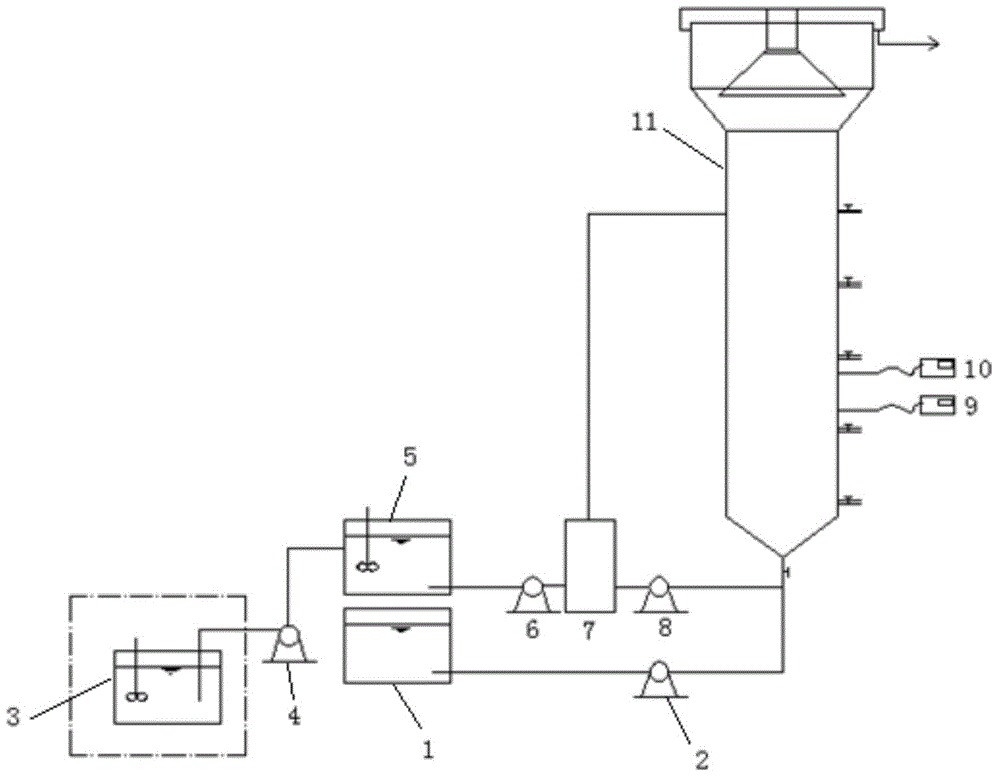

[0020] Specific implementation mode one: this embodiment mode is by continuous dosing Fe 3 o 4 The method for improving the methane production efficiency of a continuous flow anaerobic reactor by nanoparticles is carried out in the following steps:

[0021] 1. Wastewater is installed in the water distribution tank, the influent flow rate of the anaerobic reactor is controlled to be 10L / d, the hydraulic retention time is 20h, the external circulation flow rate is 100L / d, the influent COD is 5000mg / L, and the sludge concentration is 10g / L, the temperature of the anaerobic reactor is controlled at 34-36°C, by adding NaHCO 3 The solution controls the pH of the anaerobic reactor to be 6.8 to 7.2;

[0022] 2. The number of daily modulation is 2 times, and the modulation method is to add Fe 3 o 4 Nanoparticles, dosing method is solid dosing or liquid dosing, Fe 3 o 4 The particle size range of nanoparticles is 40-80nm;

[0023] When solid dosing, Fe 3 o 4 Nanoparticles are ...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, the temperature of the anaerobic reactor is controlled to 35°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, by adding NaHCO 3 The pH of the solution controlled anaerobic reactor was 7. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com