Macroporous alumina and preparation method thereof

A technology of macroporous alumina and pore volume, applied in chemical instruments and methods, alumina/aluminum hydroxide, catalyst carriers, etc., can solve the problems of cumbersome preparation steps, increased alumina production operation cost, complicated washing process, etc. Achieve the effect of inhibiting agglomeration, overcoming the dispersion of pore distribution, poor strength and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

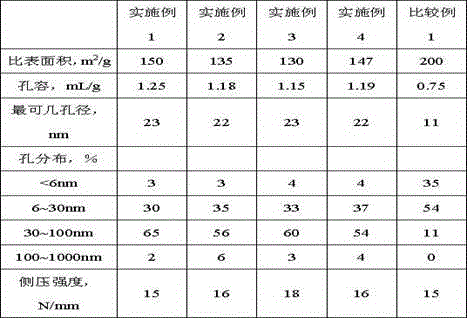

Examples

Embodiment 2

[0031] 1L sodium metaaluminate aqueous solution (A1 2 o 3 Concentration is 20g / 100ml ) and 1.5L aluminum sulfate aqueous solution (A1 2 o 3 The concentration is 5g / 100ml ) and 200mL of complex chelating agent solution (including 11 grams of methyl acetoacetate and 44 grams of acetic acid) were respectively put into high-position containers, and the flowmeter connected to the bottom flowed into a stirring tank containing 200mL of clean water. In the stainless steel reactor of the reactor and heating mantle, sodium metaaluminate aqueous solution, aluminum sulfate aqueous solution and complex chelating agent aqueous solution are fed into the reactor in parallel for gelation reaction. The system temperature is 85°C and the pH value is controlled at 9.5. The reaction was stopped after 45 minutes. Aged for 2.0 hours at a temperature of 85°C and a pH of 9.0. Filter and wash. Dry at 130°C for 4 hours, shape, then dry at 130°C for 4 hours, and then bake at 780°C for 6 hours to ...

Embodiment 3

[0033] 1.5L sodium metaaluminate aqueous solution (A1 2 o 3 Concentration is 20g / 100ml), 2.0L aluminum sulfate aqueous solution (A1 2 o 3 The concentration is 5g / 100ml) and 200mL of complex chelating agent solution (including 10 grams of butyl acetoacetate and 70 grams of formic acid) are respectively placed in a high-position container, and the bottom is connected to a flowmeter and agitator with 200mL of clean water And a stainless steel reactor with a heating jacket, sodium metaaluminate aqueous solution, aluminum sulfate aqueous solution and complex chelating agent aqueous solution flow into the reactor for gelation reaction, the system temperature is 75°C, and the pH value is controlled at 10.0. The reaction was stopped after 45 minutes. Aged for 2.0 hours at a temperature of 75°C and a pH of 10.0. Filter and wash. Dry at 120°C for 5 hours, shape, then dry at 120°C for 5 hours, and bake at 700°C for 8.0 hours to obtain sample 3.

Embodiment 4

[0035] 1.5L sodium metaaluminate aqueous solution (A1 2 o 3 Concentration is 20g / 100ml), 2.0L aluminum sulfate aqueous solution (A1 2 o 3 Concentration: 5g / 100ml) and 200mL clean water (including 60 grams of complex chelating agent, ethyl acetoacetate: 10 grams, formic acid: 50 grams), respectively put into the container at the high position, and the flow meter flows into the belt stirrer In the stainless steel reactor with heating jacket, sodium metaaluminate aqueous solution, aluminum sulfate aqueous solution and gemini surfactant solution flow into the reactor in parallel for gelation reaction. The system temperature is 85°C and the pH value is controlled at 10.5. The reaction was stopped after 45 minutes. Aged for 2.0 hours at a temperature of 85°C and a pH of 10.5. Filter and wash. It was dried at 110°C for 5 hours, shaped, then dried at 110°C for 5 hours, and then calcined at 750°C for 7.0 hours to obtain sample 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com