Welding rod packaging bag shaping device

A technology of shaping device and packaging bag, applied in the directions of packaging, transportation and packaging, winding strips, etc., can solve the problems of unsightly appearance of packaging bags, low sorting efficiency, high labor intensity, etc. High efficiency and changing the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

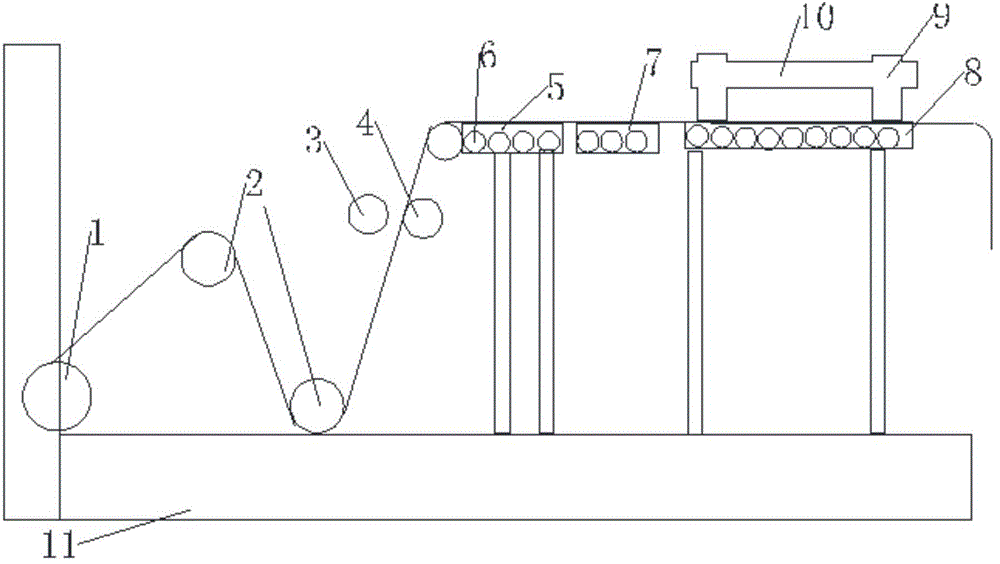

[0015] Embodiment 1: as figure 1 As shown, a welding rod packaging bag shaping device includes a transport mechanism, a vibration mechanism and a flattening mechanism. The transport mechanism includes a film shaft 1, a shaping rod 3, a fixing rod 4 and a roller 2. There is a tension sensor on the rod 3, the film shaft 1 and the roller 2 are connected to the motor 1, the roller 2 is arranged between the film shaft 1 and the shaping rod 3, the rollers 2 are arranged alternately up and down, and the fixed rod 4 is arranged on the joint The position of the shaping bar 3, the vibrating mechanism includes a vibrating mechanism frame 5, and the vibrating rollers 6 arranged side by side are arranged on the vibrating mechanism frame. A conveying device in a horizontal direction is formed. The smoothing mechanism includes an intermediate conveying mechanism 7 and a suppressing mechanism 8. The intermediate conveying mechanism 7 is located in the middle of the suppressing mechanism 8 and...

Embodiment 2

[0017] Embodiment 2: Compared with Embodiment 1, the difference of this embodiment is that the conveying bodies are all composed of juxtaposed cylindrical rollers.

[0018] The working process of this example: the same as the working process of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com