An electro-fluid dual-run drive system

A driving system and fluid technology, applied in the field of electric vehicles, can solve the problems of insufficient power supply of the battery pack, great damage to the battery, and balance problems, and achieve the effects of increasing the driving range, prolonging the discharge time, and increasing the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

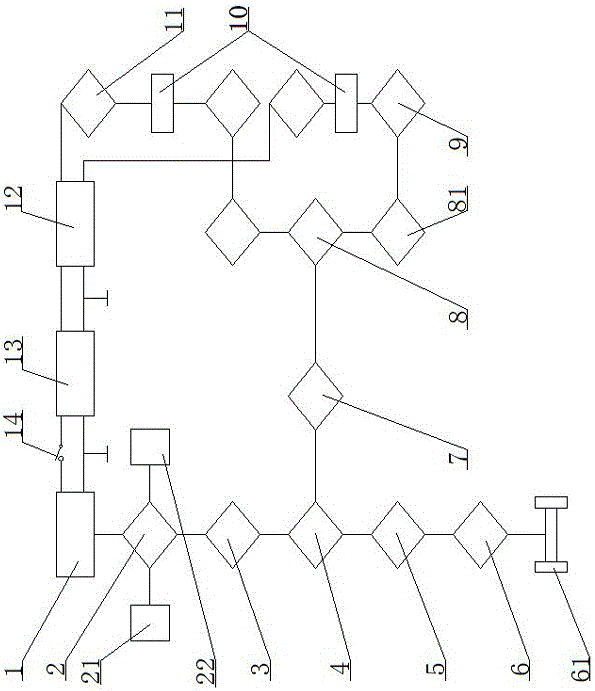

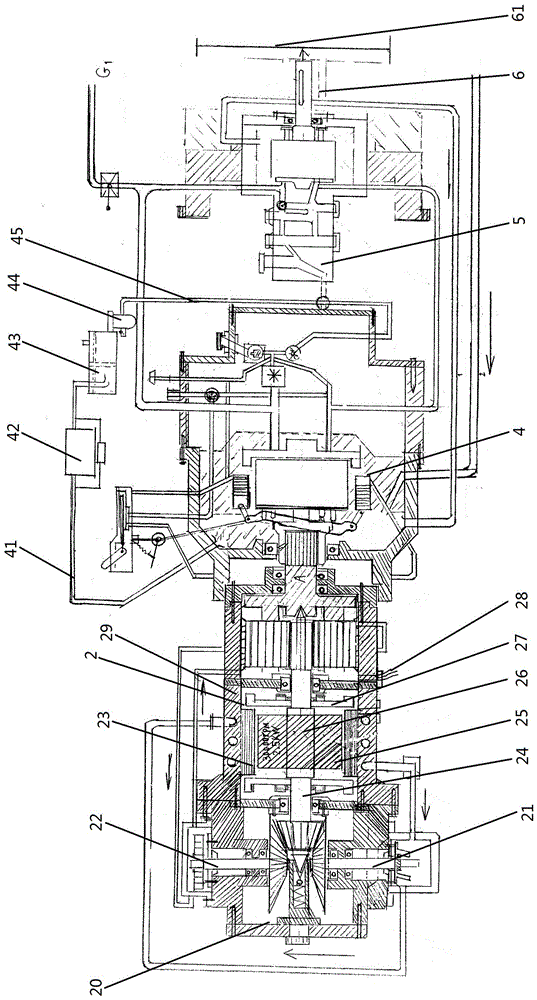

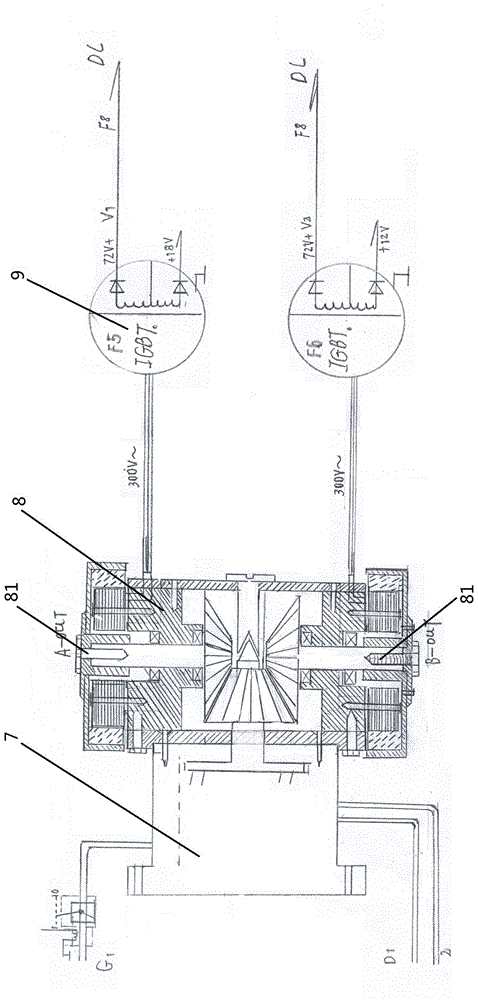

[0024] Embodiment 1. A kind of electro-fluid type dual operation drive system, such as Figure 1-4 As shown, including a battery pack 13 as a power source, the battery pack 13 adopts a 60V100AH lead-acid battery pack, and the electrical output terminal of the battery pack 13 is electrically connected to a current converter for converting low-frequency direct current into high-frequency alternating current through a wire 28 1, an open-type solid pull-in switch 14 is arranged on the wire; the electrical output end of the current converter 1 is connected to the drive motor 2 through a wire, and the motor shaft power output end of the drive motor 2 is connected to a deceleration Machine 3, the reducer 3 is connected with a double-acting liquid booster pump 4 with two liquid output ends, one liquid output end of the double-acting liquid booster pump 4 is connected with the load hydraulic motor 5, and the load hydraulic motor 5. The planetary reducer 6 is connected to the main dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com