Quantitative feeding device for looping machine

A technology of feeding device and ring ring machine, which is applied to presses, manufacturing tools, etc., can solve the problems of increasing production intensity and production cost, increasing the output time of the machine and increasing the scrap rate of workpieces, etc., to shorten the adjustment time, The effect of consistent storage volume and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

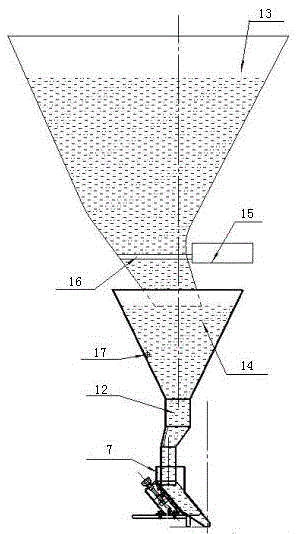

[0023] Refer to attached Figure 1-3 The shown quantitative feeding device for a ring machine includes a first silo 13, a second silo 14, a delivery hose 12, a material inlet 2, an inclined hopper 3, an adjustable discharger 7 and a fixed seat 10, Both the first silo 13 and the second silo 14 have a structure that is wide at the top and narrow at the bottom. A cylinder 15 is arranged inside the first silo 13 near the bottom, and one end of the cylinder 15 is fixedly connected to a A valve plate 16, a material level sensor 17 is arranged on the inner silo body of the second silo 14, and the material level sensor 17 is located in the middle of the silo body; the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com