Bevel processing method and the cutting tool used

A processing method and technology of chamfering, which are applied in the direction of tools, manufacturing tools, metal processing equipment, etc. for lathes, which can solve the problems of reducing processing accuracy, and achieve the goal of improving processing accuracy, reducing knife vibration, and improving product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

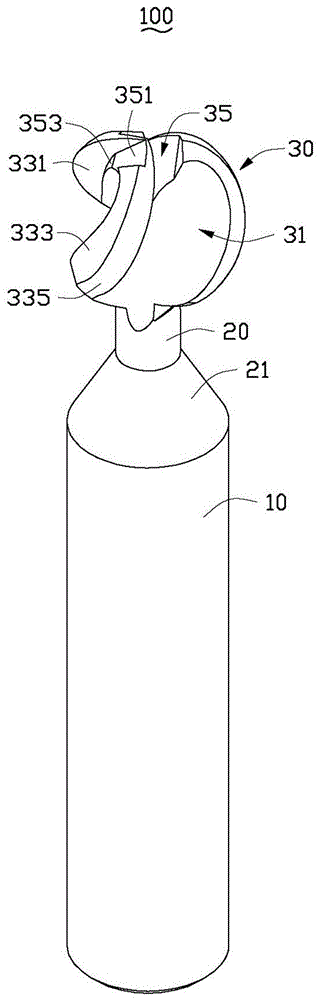

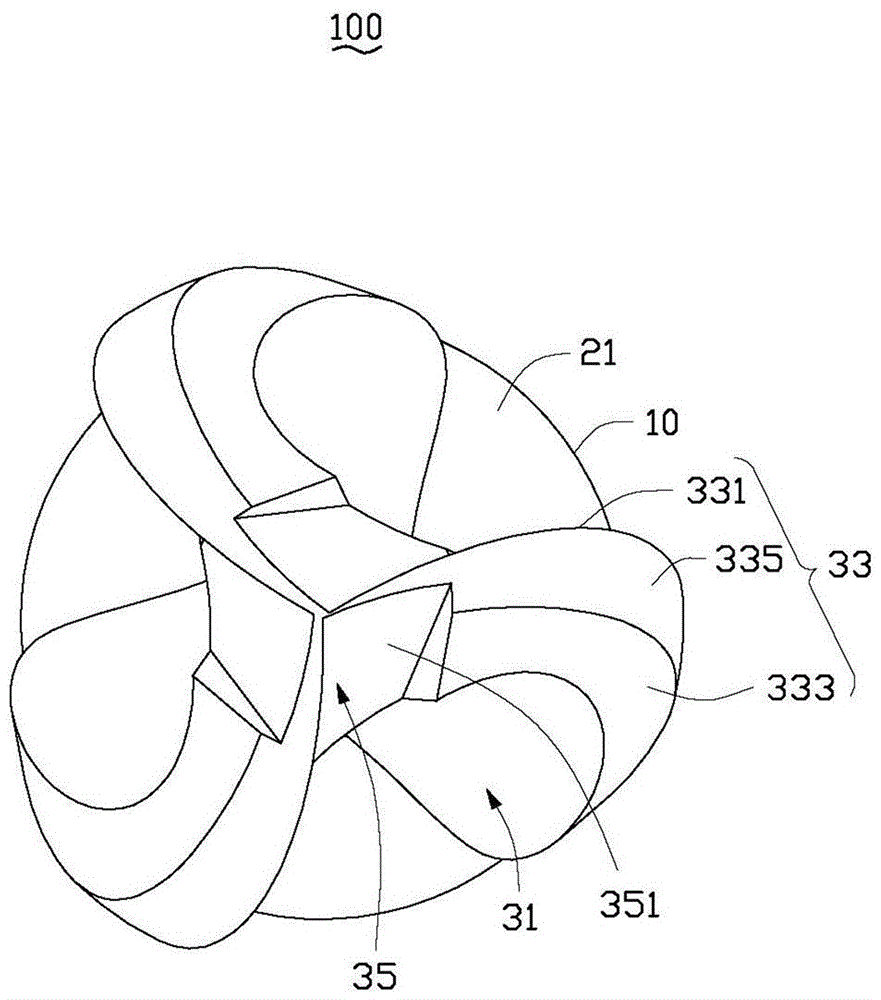

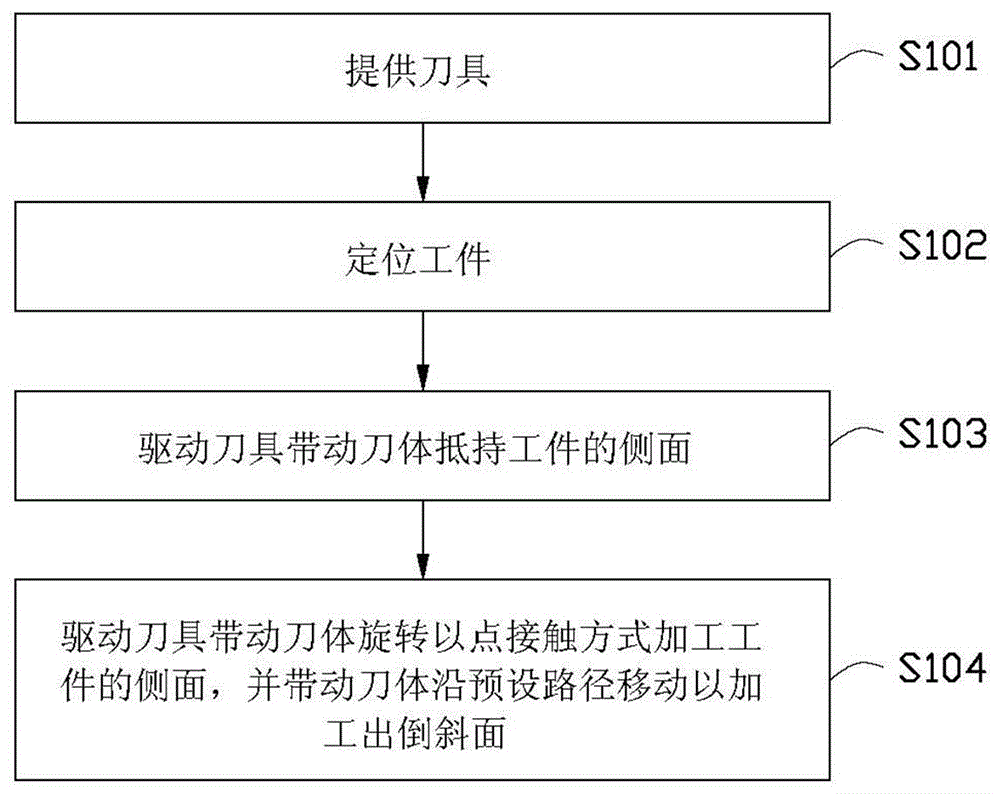

[0030] see figure 1 and figure 2 , the chamfer processing method of the embodiment of the present invention adopts cutter 100 to workpiece 200 (refer to Figure 4 ) for processing. The tool 100 includes a tool bar 10 , a relief portion 20 and a tool body 30 . The avoidance part 20 connects the knife rod 10 and the knife body 30 . The escape portion 20 is smaller in diameter than the cutter bar 10 and forms an inverted tapered surface 21 at the connection with the cutter bar 10 . The cutter body 30 is substantially spherical, and its diameter is larger than that of the cutter shaft 10 . It can be understood that the cutter body 30 can also be an ellipsoid, a T-shaped angle round nose cutter or a T-shaped ball cutter.

[0031] Three grooves 31 are evenly spaced along the periphery of the cutter body 30 to form three cutting portions 33 . The groove 31 extends away from the cutter rod 10 at an angle of 30 degrees to the axial direction of the cutter rod 10 . The cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com