Device for securing a boring bar

A fixing device, boring bar technology, applied in the direction of tools for lathes, boring bars, accessories for tool holders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

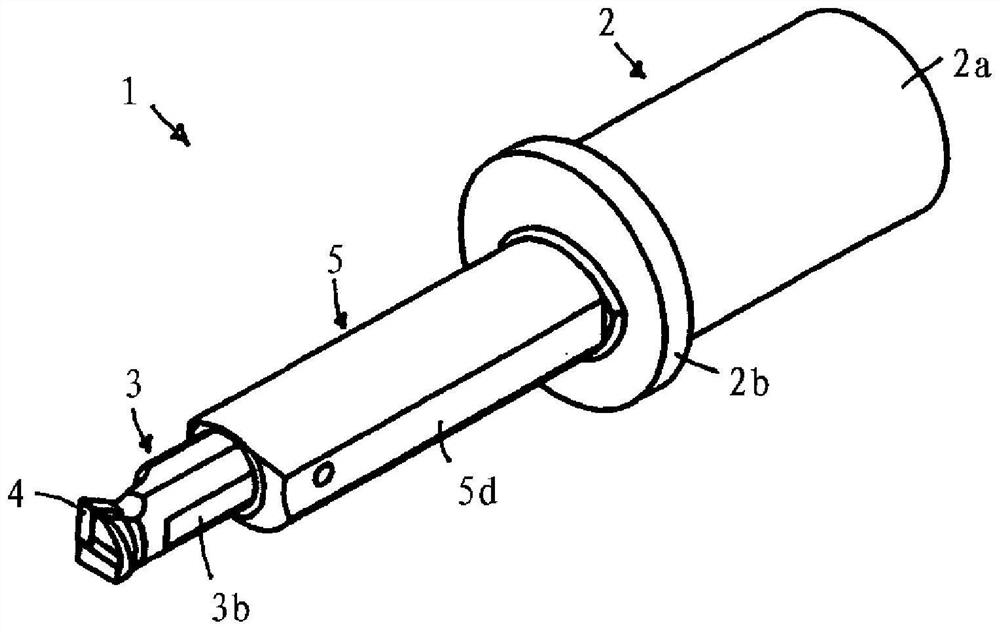

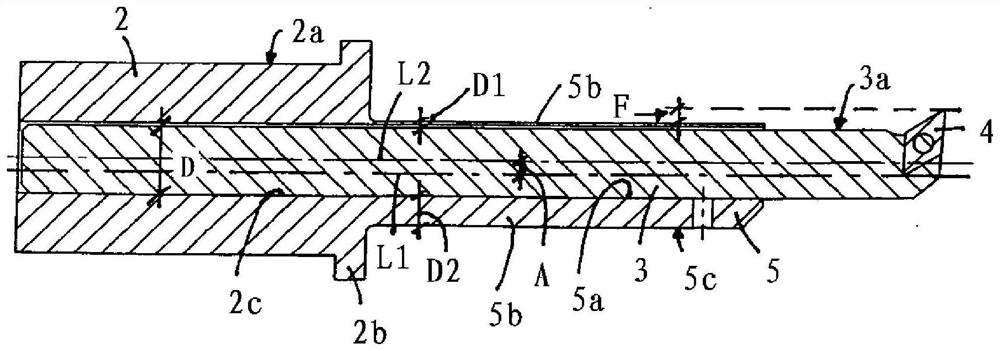

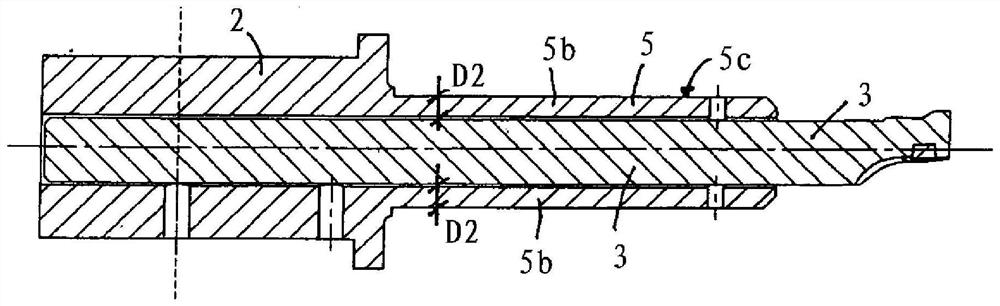

[0032] The device 1 according to the invention for fixing a boring bar 3 on a cutting machine (machine not shown) has a reducing sleeve (clamping sleeve) 2 with a cylindrical outer peripheral surface 2a, by means of The outer peripheral reducing sleeve can be fixed in the cylindrical recess of the machine chuck. The reduction sleeve has an optional flange 2b on the outer end. Furthermore, the reducing sleeve 2 has an inner longitudinal recess 2c, into which a boring bar 3 is inserted in a form-fitting, longitudinally adjustable manner, the outer peripheral surface 3a of which is cylindrical, so that the longitudinal direction of the reducing sleeve 2 The recess 2c is also cylindrical with the same diameter D. As shown in FIG. The reducing sleeve (clamping sleeve) 2 thus has the same longitudinal axis L2 as the boring bar 3 and the longitudinal recess 5 a of the hollow profile 5 .

[0033] in accordance with Figures 1 to 3 In the exemplary embodiment, the outer peripheral s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com