Double-station automatic bamboo slicing equipment

A dual-station, fragmented technology, applied in mechanical equipment, manufacturing tools, sugarcane machining and other directions, can solve the problems of high risk factor, uneven slicing, manual feeding, etc., to improve safety, solve uneven slicing, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

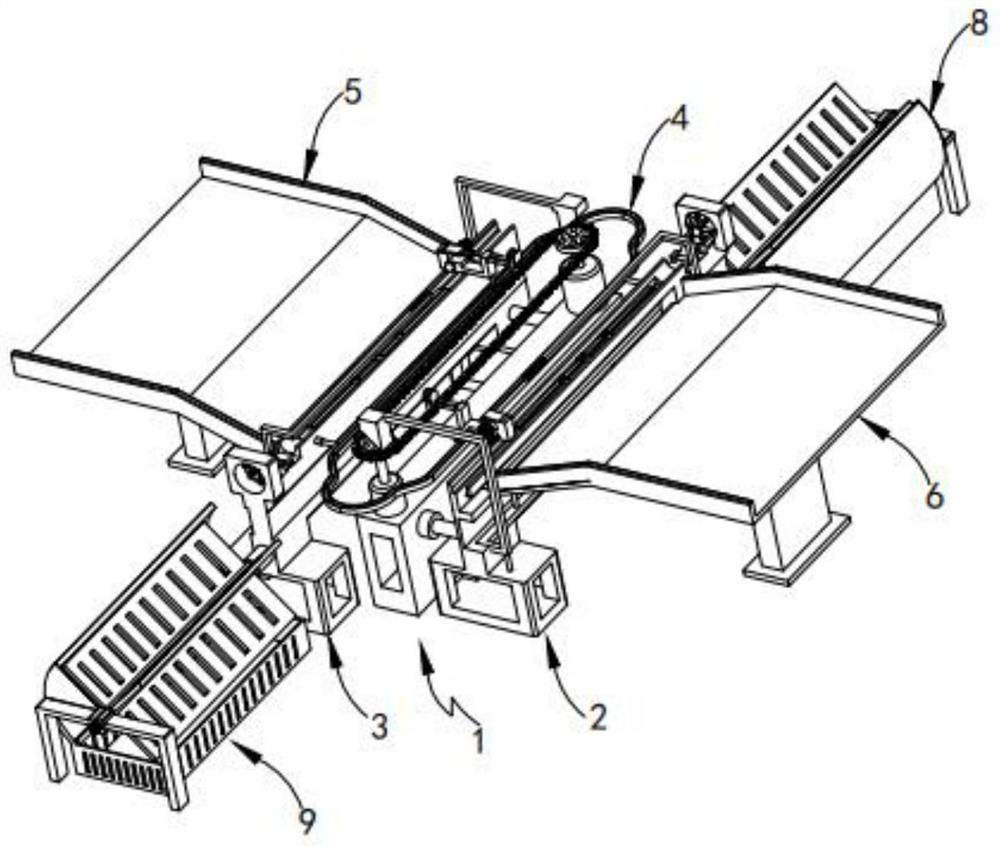

[0035] like Figure 1 to Figure 8 As shown, a double-station automatic bamboo fragmentation device includes a fragmentation device 1, and the fragmentation device 1 includes a first fragmentation mechanism 2, a second fragmentation mechanism 3, and a device between the first fragmentation mechanism 2 and the second fragmentation mechanism 3. Between the drive mechanism 4, the drive mechanism 4 includes a rotary assembly 41, a guide assembly 42, a support assembly 43, and a positioning assembly 44 arranged on the support assembly,...

Embodiment 2

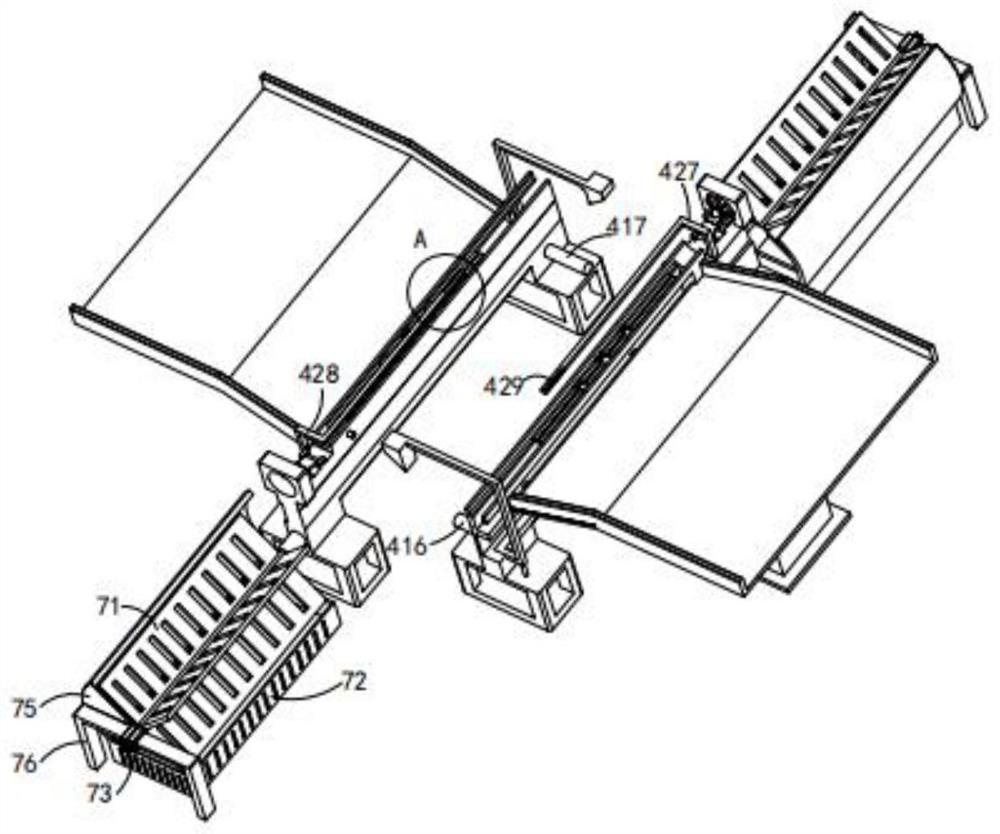

[0047] like figure 2 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that the first material receiving mechanism 8 and the second material receiving mechanism 9 both include a support rod e76, a motor b73 arranged on the support rod e76, a rotating plate 71 driven by the motor b73, and a rotating plate 71 arranged on the support rod e76. The receiving basket 72 below the rotating plate 71 and the baffle plate c75 arranged on one side of the rotating plate 71.

[0048] It is worth mentioning that in this embodiment, a material receiving mechanism is provided at the end of the fragment mechanism, and the bamboo material that has been sliced can be dropped to the material receiving plate by gravity and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com