Efficient slicer for industrial raw materials

A technology of slicers and raw materials, applied in metal processing, cooling/ventilation/heating transformation, electrical components, etc., can solve problems such as insufficient safety performance, shortened life, equipment failure, etc., to reduce the risk of injury, increase service life, The effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

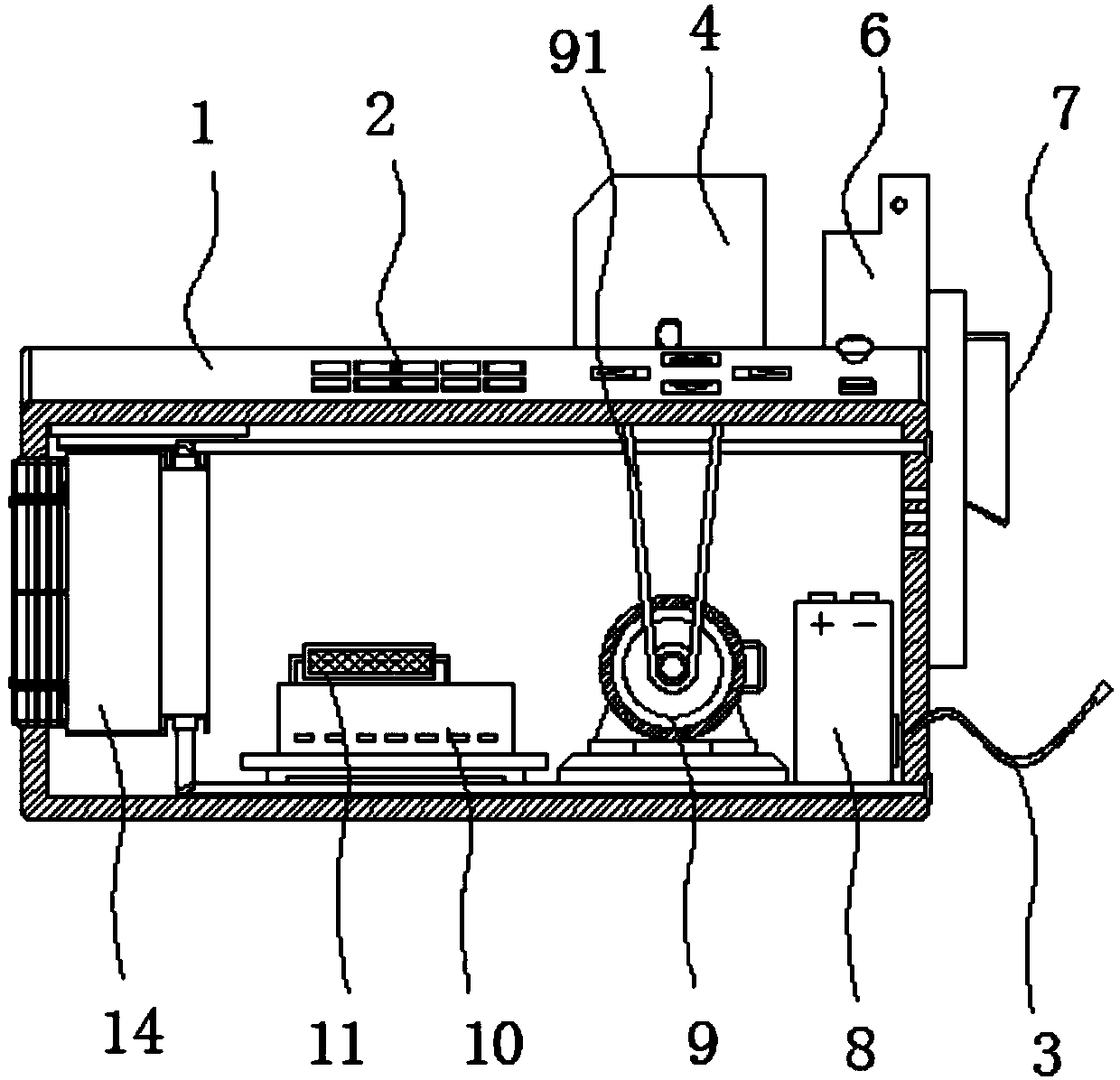

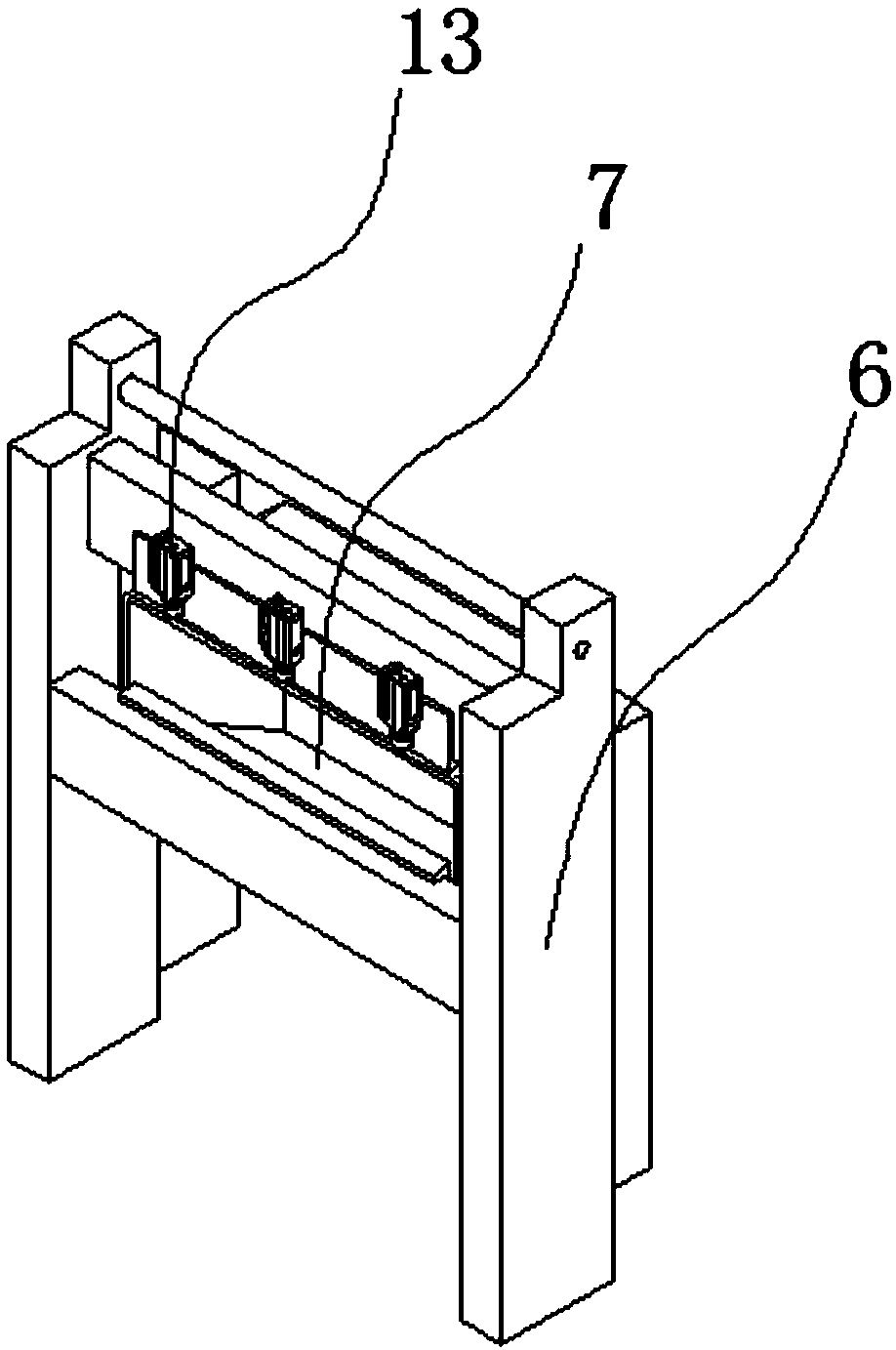

[0049] The following will be combined with Figure 1-8 The present invention is described in detail, and the technical solutions in the embodiments of the present invention are clearly and completely described. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

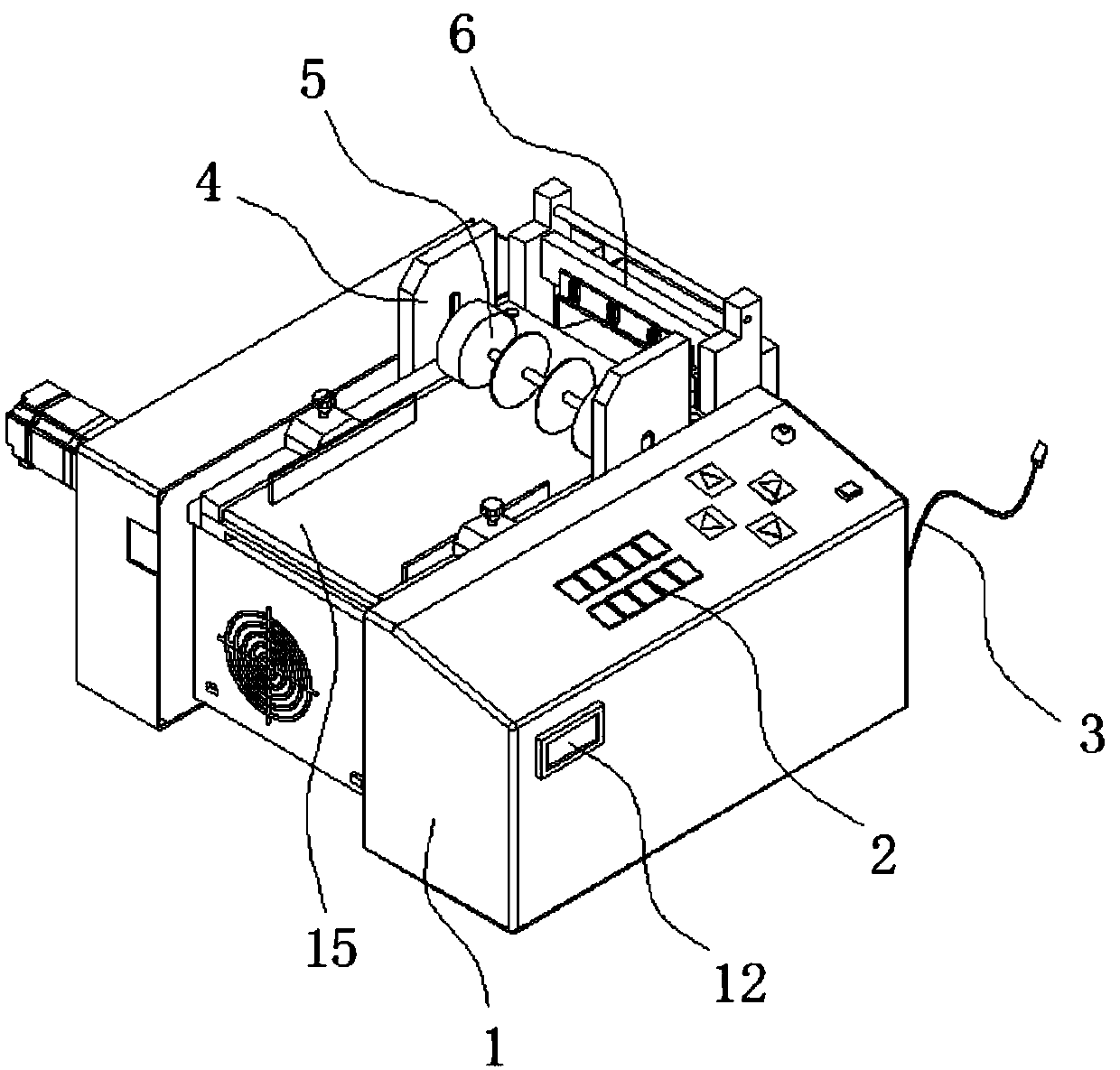

[0050] The present invention provides a high-efficiency slicer for industrial raw materials through improvement, including a chassis 1, a control panel 2, a power cord 3, a support plate 4, a cutter 5, a support frame 6, a hopper 7, a storage battery 8, and a first motor 9, belt 91, single-chip microcomputer 10, memory 11, display screen 12, infrared sensor 13, cooling device 14 and delivery device 15, the bottom of control panel 2 is bonded on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com