Method for milling step-shaped roller ring blank element by using numerical control ring milling machine

A technology of step-shaped and blank parts, which is applied in the field of rolling stepped-shaped roll ring blanks with a CNC ring rolling machine, can solve the problems of low raw material utilization rate, long rough processing process, and long production cycle, etc., to improve the utilization of raw materials The effect of reducing the rate, processing amount and reducing the processing allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

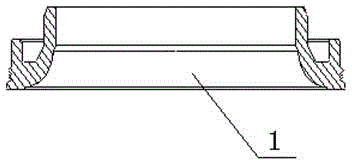

[0024] A method for rolling a stepped roller ring blank by using a numerically controlled ring rolling machine. figure 1 As shown in the finished part as an example, the method includes the following steps:

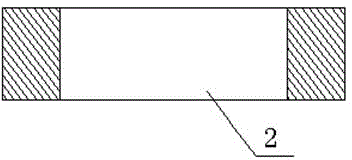

[0025] A. According to the design size, the blanking size is: a cylindrical blank with a diameter of 550mm, a height of 270mm, and a weight of 500kg.

[0026] B. Upsetting the cylindrical blank with a hammer, and stamping to make a circular cylindrical primary blank with a central through hole; the size of the primary blank is: major diameter 680mm, minor diameter 220mm, height 190mm.

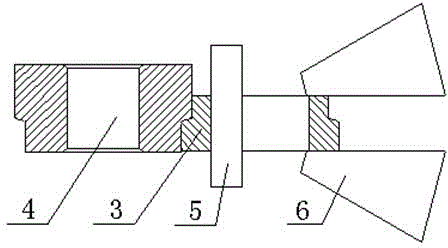

[0027] C. Install the initial blank and debug the ring rolling device of the CNC ring rolling machine. The rolling ring device such as image 3 As shown, it includes the main roll 4, the core roll 5, and the auxiliary roll. The outer ring surface of the primary bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com