Method and device for spray evaporation cooling of hot-rolled high-strength rebar

A high-strength steel bar, vaporization cooling technology, applied in the direction of metal rolling, temperature control, metal rolling, etc., to achieve the effect of improving heat exchange efficiency, improving utilization rate, reducing circulation and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Figure 1 to Figure 5 It is a specific implementation of the present invention, and its basic principles, technical features, actual operation and adjustment methods are explained as follows.

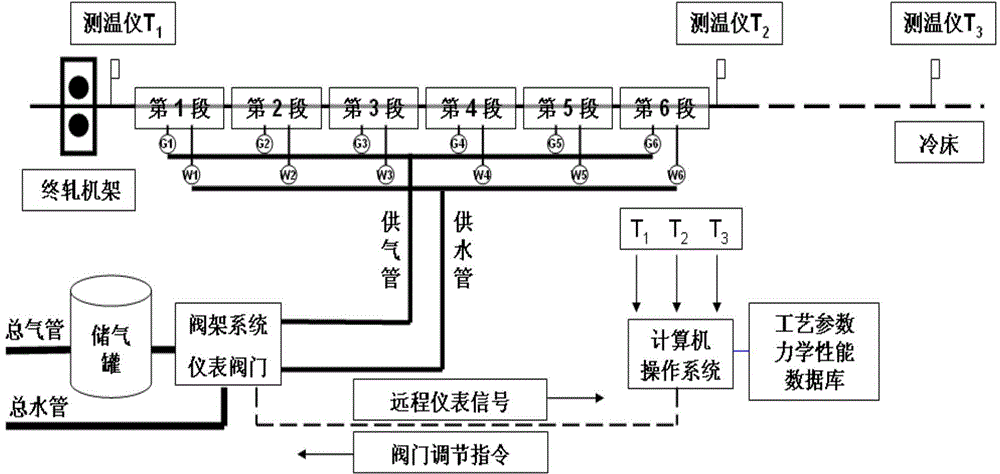

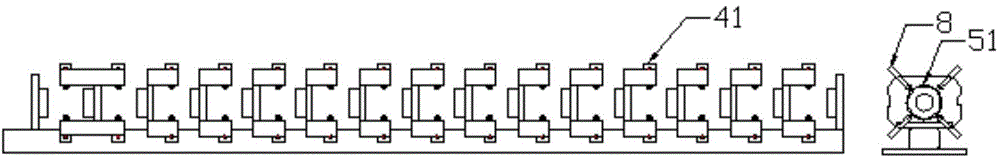

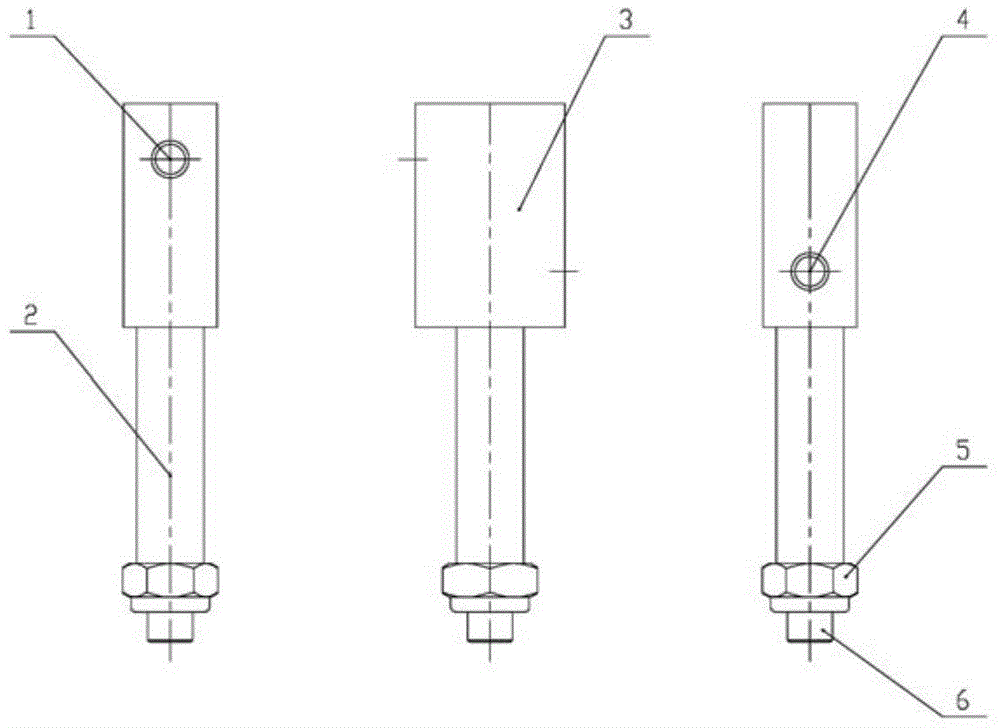

[0039] Such as figure 1 As shown, the process layout diagram of the water mist vaporization cooling device of the hot-rolled high-strength steel bar unit of the present invention mainly includes: a set of water mains, filter screens, main air pipes, gas tanks, valve holders (valves, pressure gauges, flow The water supply and air supply valve frame system consisting of water supply pipes, air supply pipes, etc.; a set of six-stage and ninety-unit water-mist vaporization cooling device composed of water-mist vaporization cooling nozzles, any section of the structure is as attached figure 2 As shown, any nozzle structure is as attached image 3 Shown; a set of computer online monitoring operating system composed of infrared thermometer, remote signal instrument, programmable controller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com