Catalyst for synthesis of polyoxymethylene dimethyl ether and application of catalyst

A technology of polyoxymethylene dimethyl ether and catalyst, which is applied in the field of synthesis of polyoxymethylene dimethyl ether, can solve the problems of poor selectivity and low yield, and achieve the effects of simple separation, high catalytic activity and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

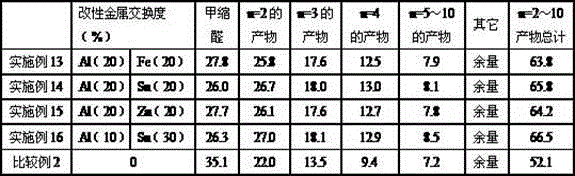

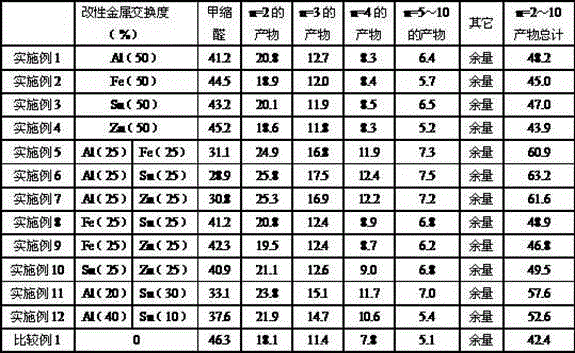

Examples

Embodiment 1

[0026] 1. Preparation of metal-modified cation exchange resin: wash 48 g of hydrogen-type styrene-based strong acid cation exchange resin with deionized water for 6 times, each time for 15 minutes, and dry in a vacuum oven at 90°C for 24 hours; Type styrene series strongly acidic cation exchange resin and 267g mass fraction are 2% AlCl 3 Stir the ethanol solution together for 10 hours, wash with absolute ethanol 6 times, each time for 15 minutes, and dry in a vacuum oven at 90°C for 24 hours to obtain a metal-modified cation exchange resin catalyst.

[0027] 2. Add 2.45g of this resin catalyst, 60g of methylal and 60g of paraformaldehyde into a 300ml tank reactor, react at 90°C and 0.4MPa autogenous pressure for 4h, extract a sample and analyze it by gas chromatography after centrifugation. The product contains polyoxymethylene dimethyl ether and unreacted raw materials, and its composition distribution is shown in Table 1.

[0028]

Embodiment 2

[0030] 1. Preparation of metal-modified cation exchange resin: wash 48 g of hydrogen-type styrene-based strong acid cation exchange resin with deionized water for 6 times, each time for 15 minutes, and dry in a vacuum oven at 90°C for 24 hours; Type styrene series strongly acidic cation exchange resin and 325g mass fraction are 2% FeCl 3 Stir the ethanol solution together for 10 hours, wash with absolute ethanol 6 times, each time for 15 minutes, and dry in a vacuum oven at 90°C for 24 hours to obtain a metal-modified cation exchange resin catalyst.

[0031] 2. Add 2.51g of this resin catalyst, 60g of methylal and 60g of paraformaldehyde into a 300ml tank reactor, react at 90°C and 0.4MPa autogenous pressure for 4h, extract a sample and analyze it by gas chromatography after centrifugation. The product contains polyoxymethylene dimethyl ether and unreacted raw materials, and its composition distribution is shown in Table 1.

[0032]

Embodiment 3

[0034] 1. Preparation of metal-modified cation exchange resin: wash 48 g of hydrogen-type styrene-based strong acid cation exchange resin with deionized water for 6 times, each time for 15 minutes, and dry in a vacuum oven at 90°C for 24 hours; Type styrene series strongly acidic cation exchange resin and 391.5g mass fraction are 2% SnCl 4 Stir the ethanol solution together for 10 hours, wash with absolute ethanol 6 times, each time for 15 minutes, and dry in a vacuum oven at 90°C for 24 hours to obtain a metal-modified cation exchange resin catalyst.

[0035]2. Add 2.58g of this resin catalyst, 60g of methylal and 60g of paraformaldehyde into a 300ml tank reactor, react at 90°C and 0.4MPa autogenous pressure for 4h, extract a sample and analyze it by gas chromatography after centrifugation. The product contains polyoxymethylene dimethyl ether and unreacted raw materials, and its composition distribution is shown in Table 1.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com