Catalyst system for desulfurization of sulfur-containing hydrocarbons, method and device for desulfurization of sulfur-containing hydrocarbons

A catalyst and technology for sulfur-containing hydrocarbons, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. The implementation effect of sulfur hydrocarbon desulfurization and the incomplete reduction of active metals, etc., can improve the activity and stability, reduce the heap ratio, and increase the wear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

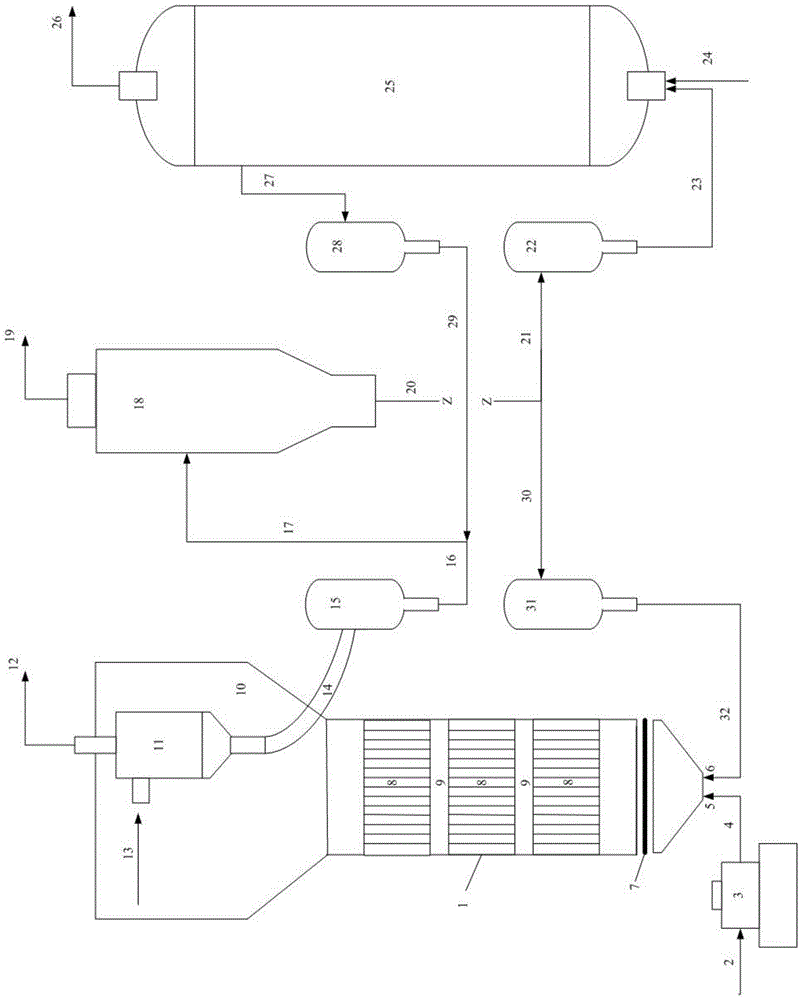

Image

Examples

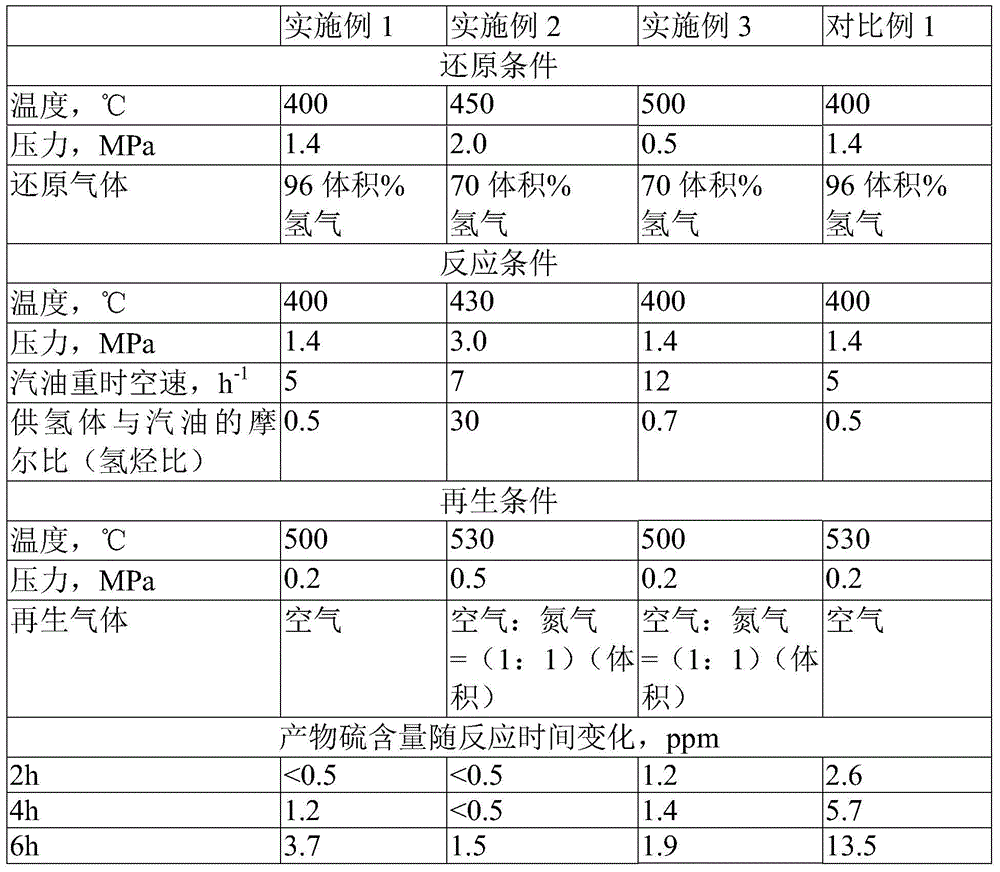

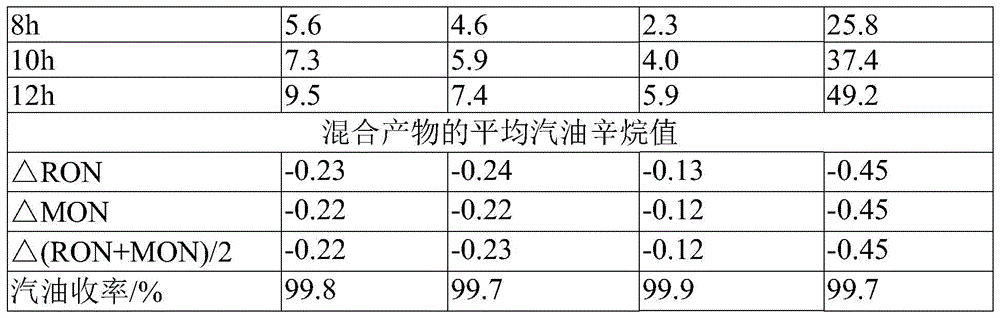

Embodiment 1

[0078] This example is used to illustrate the catalyst system and the method for desulfurizing sulfur-containing hydrocarbons of the present invention.

[0079] (1) Catalyst system. Ni / Al 2 o 3 It is the active component coating, which is coated on a cordierite honeycomb carrier (the carrier pore density is 400 pores / square inch, and the opening ratio is 70%) to obtain a catalyst with a regular structure, and the nickel content on the active component coating is 80% by weight , Al 2 o 3 The content is 20% by weight. The coating content of the active component in the catalyst was 25% by weight.

[0080] The desulfurization aid is prepared by the following method:

[0081] Mix 6.38 kg of zinc oxide powder (produced by Beijing Chemical Plant, containing 6.3 kg on a dry basis) and 8.5 kg of deionized water, and stir for 30 minutes to obtain a zinc oxide slurry.

[0082] Take 1.60 kg of alumina (produced by Shandong Aluminum Factory, including 1.20 kg on a dry basis) and 3.0...

Embodiment 2

[0087] This example is used to illustrate the catalyst system and the method for desulfurizing sulfur-containing hydrocarbons of the present invention.

[0088] (1) Catalyst system. Ni / Al 2 o 3 It is the active component coating, which is coated on a cordierite honeycomb carrier (the carrier pore density is 200 holes / square inch, and the opening ratio is 30%) to obtain a catalyst with a regular structure, and the nickel content on the active component coating is 40% by weight , Al 2 o 3 The content is 60% by weight. The coating content of the active component in the catalyst was 20% by weight.

[0089] The desulfurization aid is prepared by the following method:

[0090] Mix 8.5 kg of zinc oxide powder (produced by Beijing Chemical Plant, containing 8 kg on a dry basis) with 8.5 kg of deionized water, and stir for 30 minutes to obtain a zinc oxide slurry.

[0091] Take 1.33 kg of alumina (produced by Shandong Aluminum Factory, including 1.0 kg on a dry basis) and 1.2 kg...

Embodiment 3

[0095] This example is used to illustrate the catalyst system and the method for desulfurizing sulfur-containing hydrocarbons of the present invention.

[0096] (1) Catalyst system. Ni / Al 2 o 3 It is the active component coating, which is coated on a cordierite honeycomb carrier (the carrier pore density is 100 holes / square inch, and the opening ratio is 50%) to obtain a catalyst with a regular structure, and the nickel content on the active component coating is 70% by weight , Al 2 o 3 The content is 30% by weight. The coating content of the active component in the catalyst was 10% by weight.

[0097] The desulfurization aid is prepared by the following method:

[0098] Mix 5.1 kg of zinc oxide powder (produced by Beijing Chemical Plant, including 5.0 kg on a dry basis) and 8.5 kg of deionized water, and stir for 30 minutes to obtain a zinc oxide slurry.

[0099] Take 2.0 kg of alumina (produced by Shandong Aluminum Factory, including 1.50 kg on a dry basis) and 4.2 kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com