Preparation method of tanshinone IIA microsphere preparation

A technology of tanshinone and microspheres, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. It can solve the problem of unsatisfactory drug loading and encapsulation efficiency, poor patient compliance, and biological half-life. Short and other problems, to achieve superior sustained release, improve curative effect, reduce the effect of dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

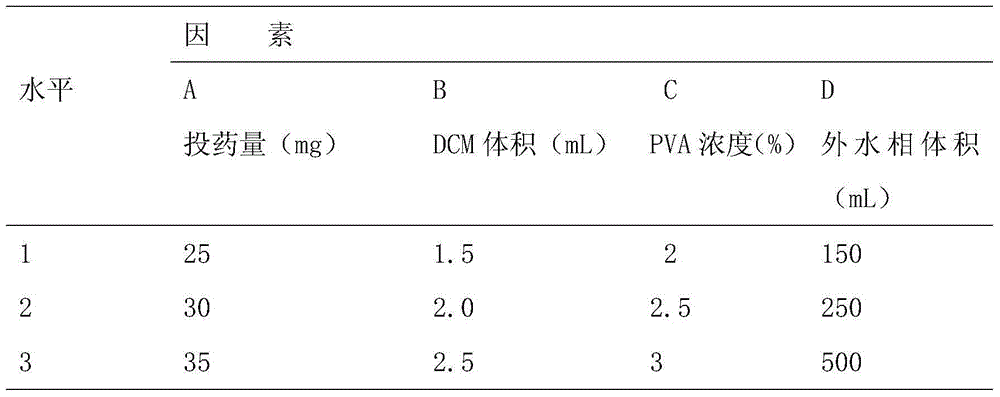

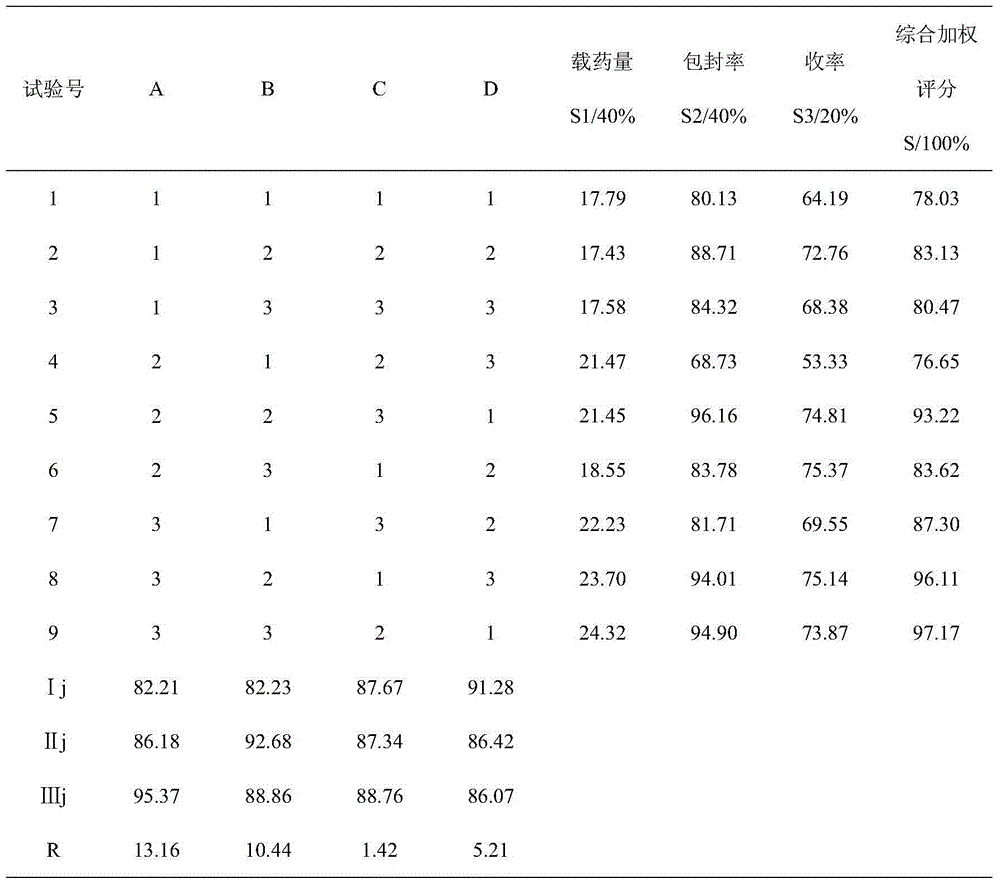

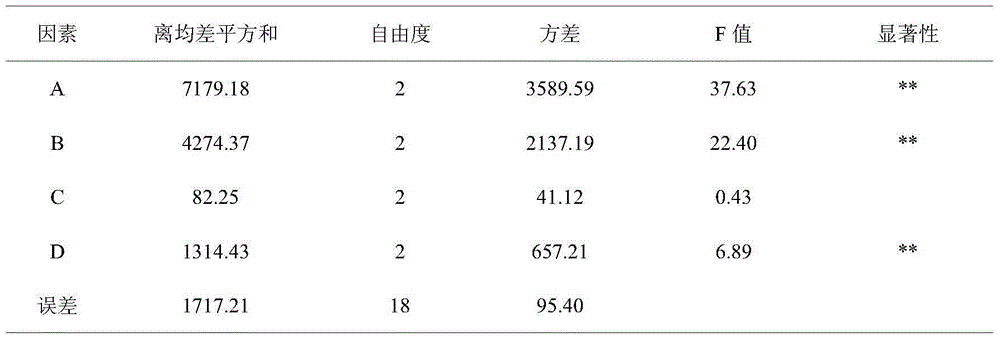

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: Tanshinone II A - Preparation of PLLA microspheres:

[0055] (1) Preparation of O phase: 10 mg of tanshinone Ⅱ A Dissolve PLLA in 2 mL of dichloromethane (DCM) to obtain a PLLA concentration of 75 g / ml, vortex and mix to form O phase, and set aside;

[0056] (2) Preparation of the W phase: dissolve the surfactant PVA in 150 mL of deionized water to obtain a PVA concentration of 3 mg / mL to form the W phase and set aside;

[0057] (3) Preparation of emulsion: Stir at a constant speed of 1000 rpm at a temperature of 4°C, slowly add the above phase O into phase W to prepare an O / W emulsion;

[0058] (4) Formation of microspheres: under ice bath conditions, stir at a constant speed at a speed of 1000 rpm until the organic solvent is completely volatilized;

[0059] (5) Collection of microspheres: leave to settle, remove supernatant, collect by suction filtration on a filter, wash with distilled water 3 times, put in a desiccator and dry at room temperature f...

Embodiment 2

[0060] Embodiment 2: Tanshinone II A - Preparation of PLLA microspheres:

[0061] (1) Preparation of O phase: 35 mg of tanshinone Ⅱ A Dissolve 75mg / mL PLLA in 1mL DCM, vortex and mix well, make phase O, set aside;

[0062] (2) Preparation of phase W: Dissolve PVA in 150 mL of deionized water to obtain a PVA concentration of 3 mg / mL to form phase W for later use;

[0063] (3) Preparation of emulsion: Stir at a constant speed of 800 rpm at a temperature of 4°C, and slowly add the above phase O into phase W to prepare an O / W emulsion;

[0064] (4) Formation of microspheres: under ice bath conditions, stir at a constant speed at a speed of 1000 rpm until the organic solvent is completely volatilized;

[0065] (5) Collection of microspheres: leave to settle, remove supernatant, collect by suction filtration on a filter, wash with distilled water 3 times, put in a desiccator and dry at room temperature for 48 hours to obtain.

Embodiment 3

[0066] Embodiment 3: Tanshinone II A Preparation of Microsphere Formulation:

[0067] (1) Preparation of O phase: 35 mg of tanshinone Ⅱ A Dissolve 75mg / mL PLLA in 2mL DCM, vortex and mix well, make phase O, set aside;

[0068] (2) Preparation of phase W: Dissolve PVA in 150 mL of deionized water to obtain a PVA concentration of 3 mg / mL to form phase W for later use;

[0069] (3) Preparation of emulsion: Stir at a constant speed of 1500 rpm at a temperature of 4°C, slowly add the above phase O to phase W to prepare an O / W emulsion;

[0070] (4) Formation of microspheres: under ice bath conditions, stir at a constant speed at a speed of 1500 rpm until the organic solvent is completely volatilized;

[0071] (5) Collection of microspheres: leave to settle, remove supernatant, collect by suction filtration on a filter, wash with distilled water 3 times, put in a desiccator and dry at room temperature for 48 hours to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com