Gutta-percha composite false tooth soft lining material and preparation method thereof

A technology of eucommia glue and denture is applied in the field of denture soft lining material and its preparation, which can solve the problems of high hardness and poor flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiments.

[0037] 1. Formulation and preparation method

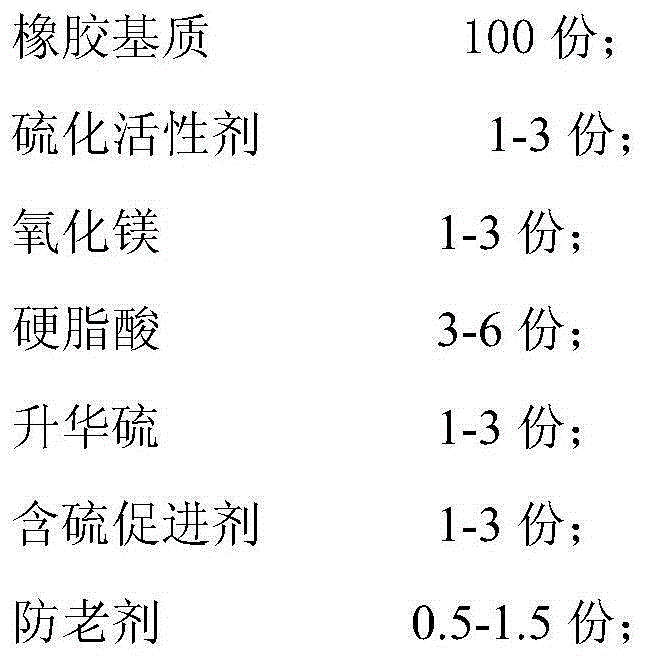

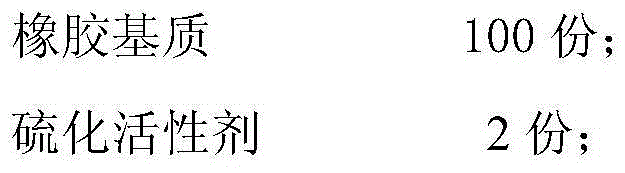

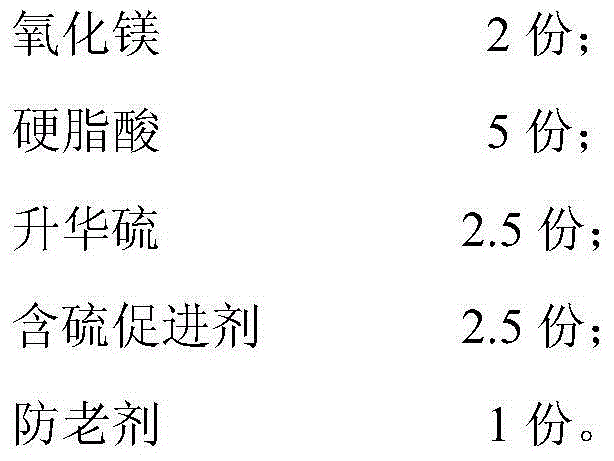

[0038] formula:

[0039]

[0040] Wherein, the rubber matrix is composed of eucommia gum and butadiene rubber, and the mass ratio of eucommia gum and butadiene rubber is 10-90:90-10.

[0041] Preparation:

[0042] According to the stated weight ratio, add eucommia ulmoides, butadiene rubber, vulcanization activator, magnesium oxide, stearic acid, and sulfur-containing accelerator in order, mix well at 70℃-80℃, and then cool down. After it reaches room temperature, add sublimated sulfur and mix well; then, after leaving it for 22-26 hours, vulcanize at 140°C-160°C for 20-40 minutes to form, and the vulcanization pressure is 9.5MPa-10.5MPa. After the material is cured, it will be demoulded.

[0043] 2. Materials and methods

[0044] 2.1 Main materials

[0045]

[0046]

[0047] 2.2 Main equipment

[0048]

[0049]

[0050] 2.3 Extraction of Eucommia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com