Manganese-based layered lithium-enriched material having one-dimensional porous structure and preparation method thereof

A technology of porous structure and lithium-rich materials, applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of material collapse and falling off, shortened cycle life, poor cycle performance, etc., to reduce stress, improve cycle performance, and high The effect of compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

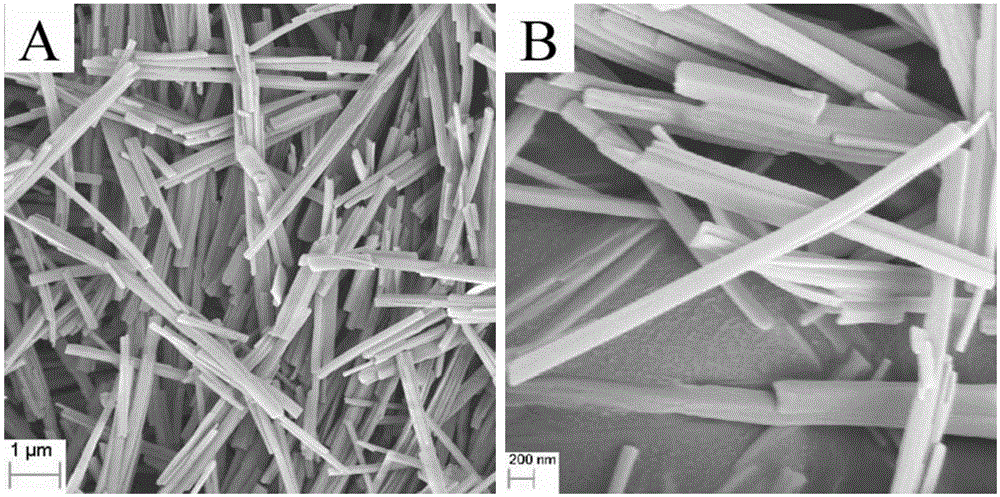

[0034] A method for preparing a manganese-based layered lithium-rich material with a one-dimensional porous structure, comprising the following steps:

[0035] (1) Add 15mL deionized water into a 500mL high-necked beaker, and then stir at a stirring speed of 300r·min -1 Add 1.52g oxalic acid under the condition of oxalic acid and make it fully dispersed to obtain oxalic acid solution;

[0036] Under mechanical stirring at 500r / min, add 10g CTAB to the oxalic acid solution, keep stirring for 30min, then add 300mL cyclohexane and 10mL n-pentanol, keep stirring for 1.5h to obtain solution A;

[0037] (2) Under the mechanical stirring of 1000r / min, slowly add 5mL of 0.06mol·L-1 Manganese acetate and 0.09mol·L -1 Cobalt acetate mixed solution, reacted for 12h, and then at 20000r·min -1 centrifuged at low temperature, washed 5 times with absolute ethanol, and vacuum-dried at 60°C for 12 hours to obtain oxalate micro-nanorods with a one-dimensional structure;

[0038] (3) The oxal...

Embodiment 2

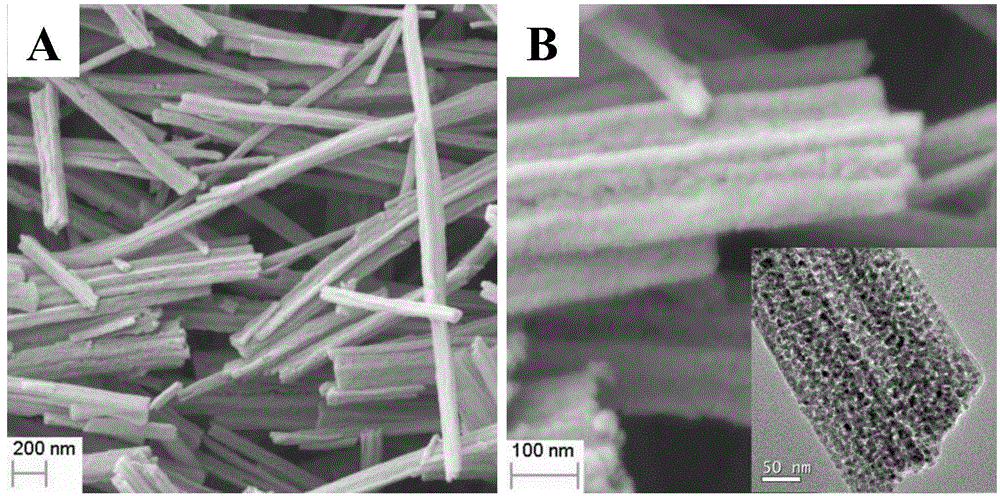

[0041] A method for preparing a manganese-based layered lithium-rich material with a one-dimensional porous structure, comprising the following steps:

[0042] (1) Add 20mL deionized water into a 1000mL high-necked beaker, and then stir at a stirring speed of 500r·min -1 Add 2.53g oxalic acid under the condition of oxalic acid and make it fully dispersed to obtain oxalic acid solution;

[0043] Under mechanical stirring at 800r / min, add 18g CTAB to the oxalic acid solution, keep stirring for 1h, then add 700mL cyclohexane and 30mL n-pentanol, keep stirring for 2h, to obtain solution A;

[0044] (2) Under the mechanical stirring of 800r / min, slowly add 40mL of 0.05mol·L -1 Manganese chloride and 0.2mol·L -1 mixed solution of cobalt chloride, reacted for 8h, and then at 15000r·min -1 centrifuged at low temperature, washed 3 times with absolute ethanol, and vacuum-dried at 40°C for 15 hours to obtain oxalate micro-nanorods with a one-dimensional structure;

[0045] (3) The ox...

Embodiment 3

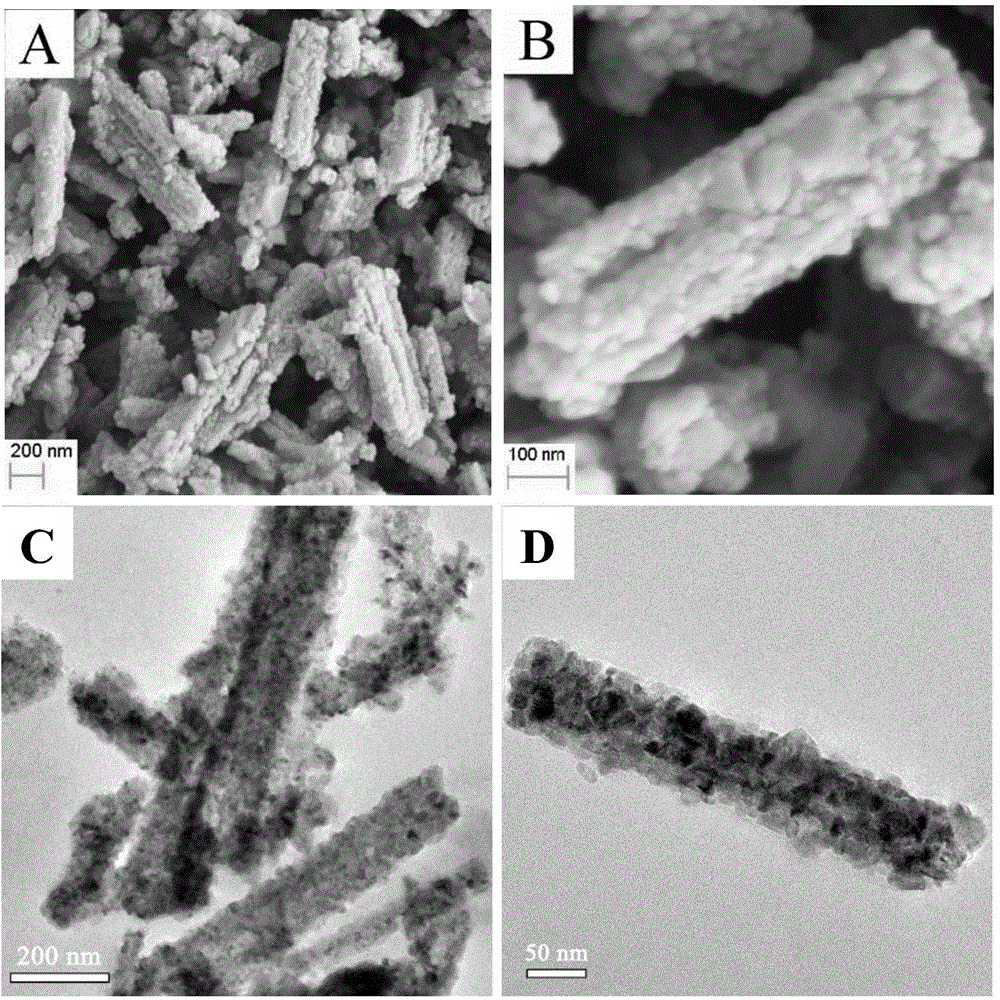

[0048] A method for preparing a manganese-based layered lithium-rich material with a one-dimensional porous structure, comprising the following steps:

[0049] (1) Add 4mL deionized water into a 100mL high-necked beaker, and then stir at 400r·min -1 Add 0.25g oxalic acid under the condition of oxalic acid and make it fully dispersed to obtain oxalic acid solution;

[0050] Under mechanical stirring at 600r / min, add 2g CTAB to the oxalic acid solution, keep stirring for 40min, then add 30mL cyclohexane and 1.5mL n-pentanol, keep stirring for 1.5h to obtain solution A;

[0051] (2) Under mechanical stirring at 900r / min, slowly add 4 mL of 0.5 mol·L -1 manganese nitrate and 0.125mol L -1 Cobalt nitrate mixed solution, reacted for 10h, and then at 19000r·min -1 centrifuged at low temperature, washed 4 times with absolute ethanol, and vacuum-dried at 80°C for 20 hours to obtain oxalate micro-nanorods with a one-dimensional structure;

[0052] (3) The oxalate micro-nanorods with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com