Technology for preparing multilayer film thermoelectric materials through physical vapor deposition method

A technology of physical vapor deposition and thermoelectric materials, which is applied in the field of preparation of functional device materials, can solve the problems that cannot meet the needs of the development and application of thermoelectric materials, the combination of samples and substrates is not good, and the purity of the multilayer film structure is affected. The composition and thickness are controllable, the boundary of the film layer is obvious, and the effect of overcoming the poor thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

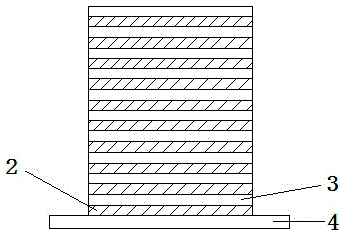

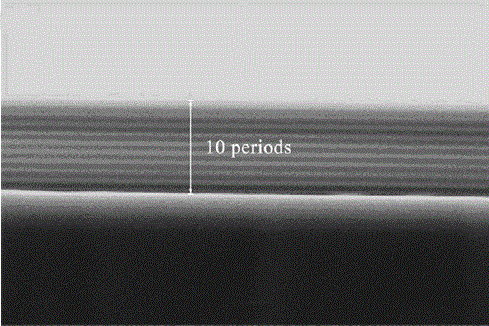

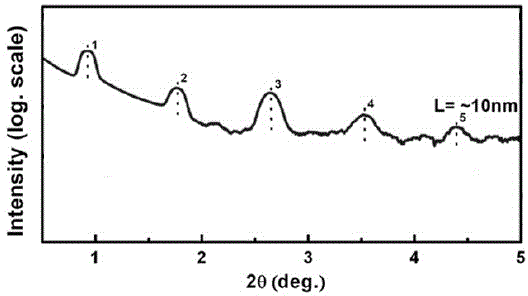

[0024] In this example, see Figure 1 ~ Figure 3 , a process for preparing a multilayer thermoelectric material by physical vapor deposition method, comprising the following steps:

[0025] a. Selection and treatment of the substrate: select the substrate type as Si, and its resistivity is 1000 Ω·cm. First, use BOE solution (hydrogen fluoride: ammonium fluoride = 1:5) to soak the Si substrate for 5 minutes for hydrofluoric acid treatment, then use acetone and ethanol solutions for ultrasonic cleaning for 10 minutes, then use acetone, absolute ethanol, The silicon wafers were cleaned successively with deionized water, then dried with high-purity nitrogen, and finally placed in a drying oven at 80 °C for 15 minutes before being used;

[0026] b. Selection of target material: select silicon and silicon germanium materials with a mass percentage purity of 99.99% as the target material, wherein the silicon germanium material includes 25wt% silicon and 75wt% germanium;

[0027] c....

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, especially in that:

[0034] In this example, see Figure 4 , a process for preparing a multilayer thermoelectric material by physical vapor deposition method, comprising the following steps:

[0035] a. selection of substrate and its processing: this step is the same as in Example 1;

[0036] b. Selection of target materials: silicon and gold with a mass percentage purity of 99.99% are selected as target materials;

[0037] c. Fabricate multilayer thermoelectric materials on the substrate: the background vacuum is 5×10 -7 Torr, the substrate is not heated, and the substrate speed is kept at 20rpm. Use RF mode to sputter silicon, and DC mode to sputter gold. The sputtering power of silicon is 100 W, and its deposition rate is about 0.2 ? / s. The radiation power is 25W, the deposition rate is about 0.6 ? / s, and the film thicknesses of silicon and gold are controlled to be 12 nm and 16 nm respectively. The gold la...

Embodiment 3

[0041] This embodiment is basically the same as the previous embodiment, and the special features are:

[0042] In this example, see Figure 5 , a process for preparing a multilayer thermoelectric material by physical vapor deposition method, comprising the following steps:

[0043] a. selection of substrate and its processing: this step is the same as in Example 1;

[0044] b. Selection of target material: select silicon, gold and silicon-germanium materials with a mass percentage purity of 99.99% as the target material, wherein the silicon-germanium material includes 25wt% silicon and 75wt% germanium;

[0045] c. Fabricate multilayer thermoelectric materials on the substrate: the background vacuum is 5×10 -7 Torr, the substrate is not heated, and the substrate speed is kept at 20rpm, and the RF mode is used to sputter silicon and silicon germanium. The sputtering mode of gold is DC mode, the sputtering power of silicon is 100 W, and the deposition rate is about 0.2 ? / s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com