Integrated terminal device used for power cable step-by-step puncture test

A breakdown test and power cable technology, applied in the direction of testing dielectric strength, etc., can solve problems such as troublesome operation, achieve convenient loading and unloading process, reduce site occupation, convenient and reliable connection of heating and voltage application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

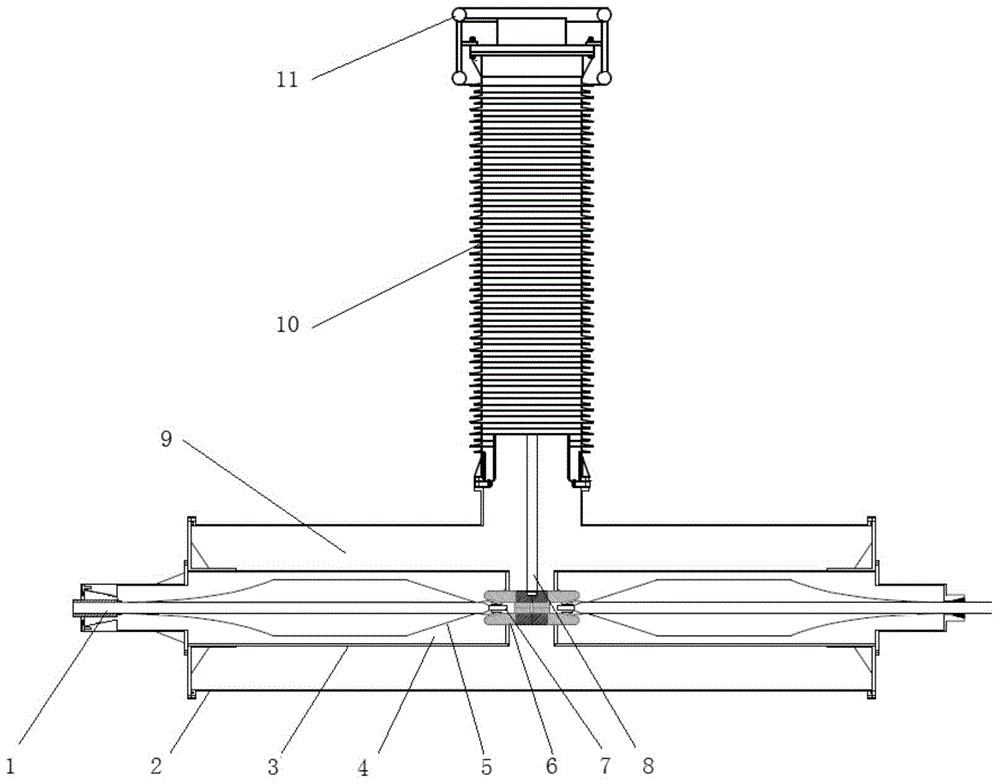

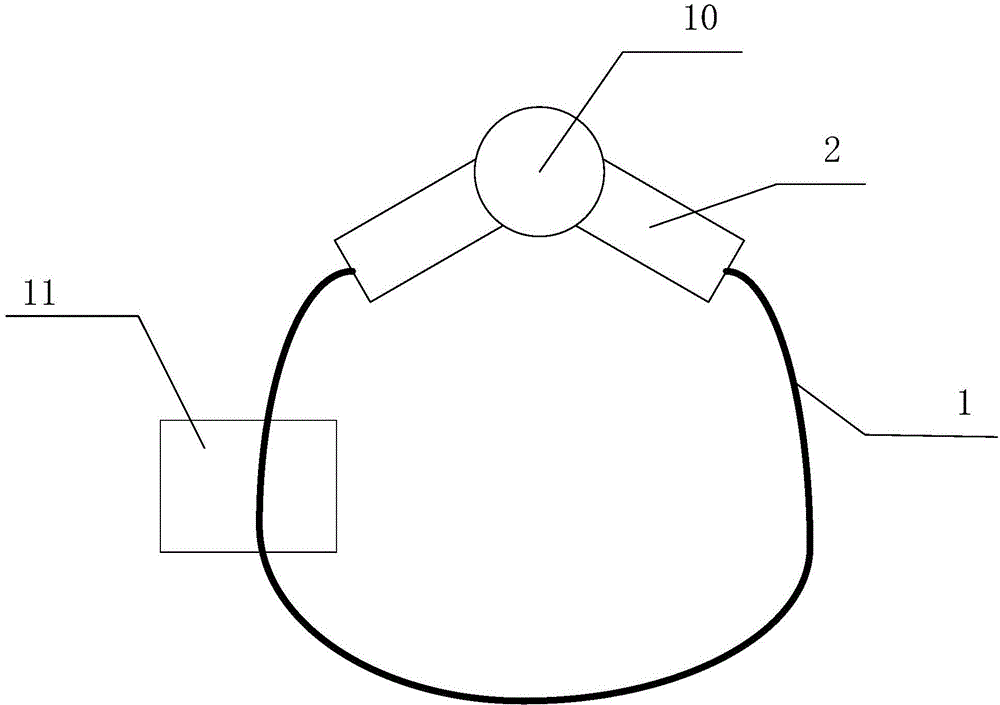

[0030] An integrated terminal device for step-by-step breakdown tests of power cables, such as figure 1 As shown, it includes a cable connection fixture 6, a high-voltage lead-out rod 8, a housing and a cable heating assembly, wherein the cable connection fixture 6 includes two clamps, and the two clamps are used to clamp the two ends of the cable 1 respectively. The lead-out rod 8 is connected with the cable connection fixture 6, and is used to apply a test voltage to both ends of the cable 1, and the housing includes a high-voltage bushing 10 for accommodating the high-voltage lead-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com