Method for preparing nano-aluminum-nitride reinforced aluminum-based composite semi-solid slurry based on ultrasonic and mechanical vibration combination

A nano-aluminum nitride and semi-solid slurry technology is applied in the field of preparation of aluminum-based composite material semi-solid slurry, which can solve the problems of complex process, limited molding and low content, and achieves low process cost, convenient operation, Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

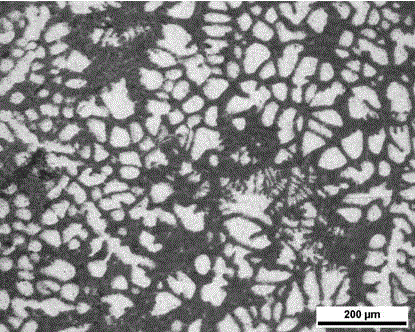

Embodiment 1

[0012] First, mix the nano-aluminum nitride particles and aluminum powder for ball milling for 60 hours, wherein the mass ratio of nano-aluminum nitride particles to aluminum powder is 2:3, and the ball milling speed is 70rpm; put the mixed powder into the crucible for heating, and the temperature is controlled at 660°C; air cooling, crushing, and sieving, the mesh size of which is 850μm; put the 7075 aluminum alloy into the crucible to heat and melt, at a temperature of 700°C, the amount of nano-aluminum nitride particles added is the aluminum alloy melting The amount of 1wt.% of the body, the above-mentioned mixed powder after sieving is added to the 7075 aluminum alloy melt, the addition time is 5min, and high-energy ultrasound is introduced into the aluminum alloy melt during the addition process, the ultrasonic frequency is 20KHz, and the power is 1KW , and then continue ultrasonic treatment for 5 minutes; reduce the melt temperature to 635 ° C, the cooling rate is 5 ° C / ...

Embodiment 2

[0014] First, mix the nano-aluminum nitride particles and aluminum powder for ball milling for 50 hours, wherein the mass ratio of nano-aluminum nitride particles to aluminum powder is 1:1, and the ball milling speed is 60rpm; put the mixed powder into a crucible for heating, and the temperature is controlled at 670°C; air cooling, crushing, and sieving, the mesh size of which is 1000μm; put the 6063 aluminum alloy into the crucible to heat and melt, at a temperature of 750°C, the amount of nano-aluminum nitride particles added is the aluminum alloy melting The amount of 2wt.% of the body, the above-mentioned mixed powder after sieving is added to the 6063 aluminum alloy melt, the addition time is 10min, and high-energy ultrasound is introduced into the aluminum alloy melt during the addition process, the ultrasonic frequency is 20KHz, and the power is 2KW , and then continue ultrasonic treatment for 5 minutes; reduce the melt temperature to 652 ° C, the cooling rate is 10 ° C ...

Embodiment 3

[0016] First, mix the nano-aluminum nitride particles and aluminum powder for ball milling for 60 hours, wherein the mass ratio of nano-aluminum nitride particles to aluminum powder is 1:1, and the ball milling speed is 70rpm; put the mixed powder into a crucible for heating, and the temperature is controlled at 660°C; air-cooled, crushed, and sieved, with a mesh size of 850 μm; put the A356 aluminum alloy into a crucible to heat and melt, and at a temperature of 700°C, the amount of nano-aluminum nitride particles added is The amount of 1wt.% of the body, the above-mentioned mixed powder after sieving is added to the A356 aluminum alloy melt, the addition time is 5min, and high-energy ultrasound is introduced into the aluminum alloy melt during the addition process, the ultrasonic frequency is 20KHz, and the power is 1KW , and then continue ultrasonic treatment for 5 minutes; reduce the melt temperature to 605 ° C, the cooling rate is 15 ° C / min, this process is applied mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com