Bacillus amyloliquefaciens gfj-4 and bacillus amyloliquefaciens gfj-4 containing composition

A technology of gfj-4 and amylolytic spores, which is applied in the field of microorganisms, can solve problems such as difficult biodegradation and ecological environment damage, and achieve the effects of good environmental compatibility, reduced usage, and reduced residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

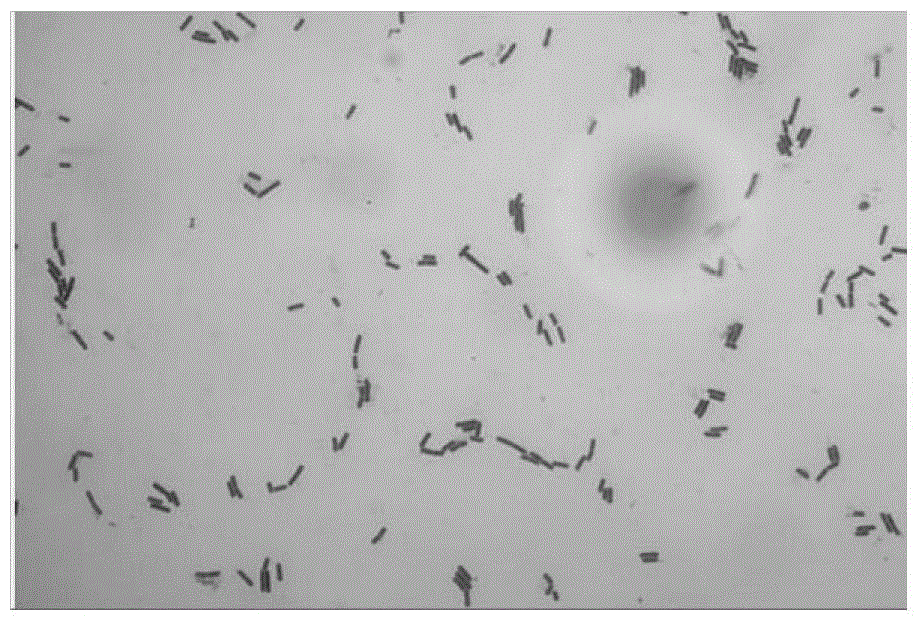

[0028] Identification of embodiment 1 biocontrol strain

[0029] In this study, a bacterium gfj-4 with broad-spectrum antagonistic activity against phytopathogenic fungi was isolated from the collected diseased tomato fruits. The strain was observed through the combination of morphological observation, physiological and biochemical characteristics analysis and 16S rRNA gene sequence analysis. Identified as Bacillus amyloliquefaciens.

[0030] The isolation and purification process of strain gfj-4 is as follows:

[0031] 1) Bacteria solution preparation

[0032] Disinfect the surface of the collected diseased tomato fruits with medical cotton balls soaked in 75% alcohol, then cut the fruits with a sterile scalpel and put them in a sterile mortar to fully grind and homogenate, and then use the stepwise dilution method to homogenize the fruit. Gradiently dilute the slurry to three concentrations of 10-2, 10-3 and 10-4 for later use.

[0033] 2) Aseptic culture

[0034] First,...

Embodiment 2

[0049] The antibacterial activity of embodiment 2 bacillus amyloliquefaciens gfj-4

[0050] 1. Preparation of fermentation medium

[0051] Potato (peeled) 200.0g, glucose 18.0g, magnesium sulfate 1.0g, ammonium nitrate 1.0g, potassium dihydrogen phosphate 0.60g, deionized water 1.0L, 16% agar strips can be added to make a solid medium for use.

[0052] 2. Preparation of inactivated fermentation broth

[0053] Cultivate Bacillus amyloliquefaciens gfj-4 strain on the ordinary medium plate for 48 hours, pick a single colony lawn and transfer it to the fermentation medium, shake culture at 33°C, 140r min-1 for 72 hours, and then put the cultured The fermentation broth was sterilized in a high-pressure steam sterilizer at 115°C for 20 minutes. Then put the inactivated fermented liquid in a centrifuge at 8000r min -1 , 15°C, centrifuge for 30min, take the supernatant and store it in a 4°C refrigerator for later use.

[0054] 3. Determination of antibacterial activity

[0055] U...

Embodiment 3

[0072] Synergistic combination of embodiment 3 inactivated fermented liquid and chemical bactericide

[0073] Adopt mycelia growth rate method to draw, the inhibition rate of 10-fold dilution of biocontrol bacterium inactivated fermented liquid reaches 50% to Fusarium graminearum mycelia growth, and 8 kinds of chemical fungicides to the growth rate of Fusarium graminearum mycelia EC50 are: the EC500.06μg / mL of fludioxonil, 0.85μg / mL of carbendazim, 0.32μg / mL of tebuconazole, 1.71μg / mL of difenoconazole and 1.80μg / mL of myclobutanil mL, thiram is 8.90 μg / mL, mancozeb is 11.16 μg / mL and triadimefon is 9.65 μg / mL.

[0074] The toxicity test design of Horsfall was used to study the inhibitory effect of the mixture of inactivated fermentation broth and chemical fungicides on Fusarium graminearum. The calculation formula of Horsfall toxicity test is as follows:

[0075] Actual bacteriostatic rate (%)=[(control colony diameter-treatment colony diameter) / (control colony diameter-bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com