A kind of plugging agent for drilling fluid and preparation method thereof

A technology of plugging agent and drilling fluid, which is applied in the field of plugging agent for drilling fluid and its preparation, and achieves the effects of less investment in equipment, mild preparation process conditions, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

[0031] The plugging agent for drilling fluid of the present invention, its components by weight percentage include: acrylamide 23, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) 0.5, acryloyloxyethyltrimethylammonium chloride ( DAC) 2.3, soda ash 0.9, high viscoelasticity modifier polyvinylpyrrolidone 7.0 and cross-linking agent trimethylolpropane tris(3-aziridinyl propionate) 0.002, the rest is deionized water. The conductivity of deionized water is 19µs / cm.

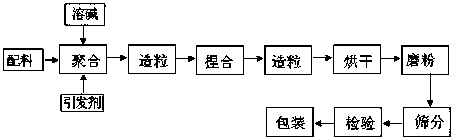

[0032] The preparation process of the lost circulation agent for drilling fluid of the present invention is as follows figure 1 shown, including the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com