Phase change cold accumulation composite material based on polyethylene glycol

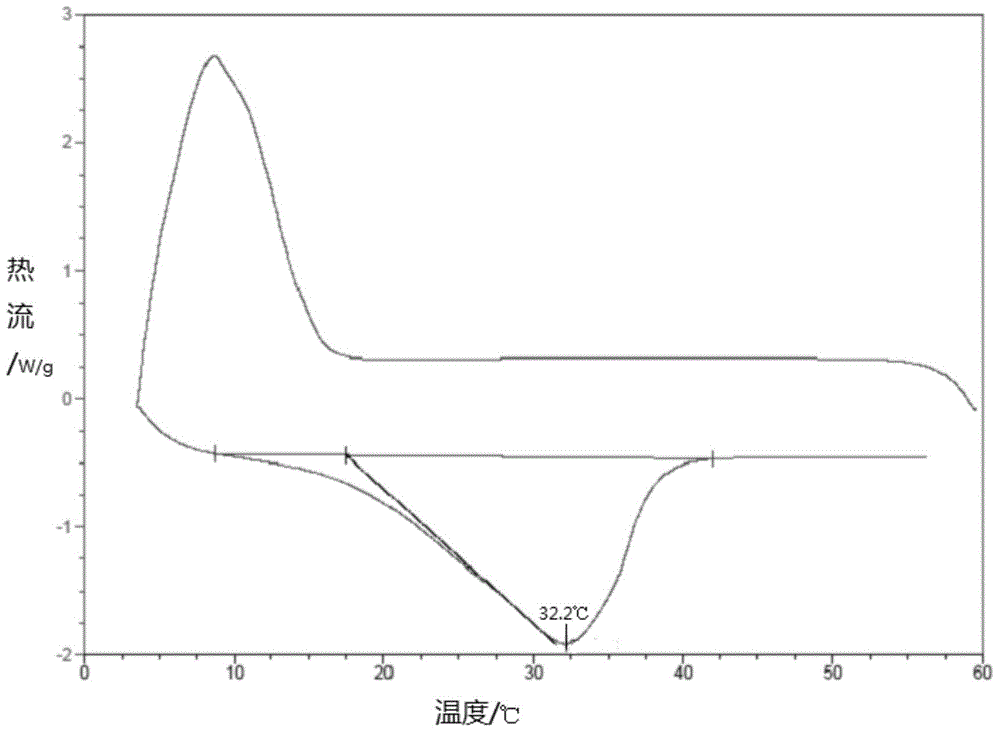

A phase change cold storage and composite material technology, applied in the field of composite materials, can solve the problems of packaging leakage and cleaning trouble, and achieve the effects of high phase change heat, cold storage capacity retention, and low phase transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] According to another aspect of the present invention, a kind of preparation method of polyethylene glycol-based phase change cold storage composite material is provided, the method comprises the following two steps:

[0090] Step 1, polyethylene glycol and solvent are added in the container.

[0091] In the above step 1, the parts by weight of the polyethylene glycol are 8-10 parts, and the parts by weight of the solvent are 0.3-5 parts, wherein,

[0092] The molecular weight of the polyethylene glycol is 400-2000, and the solvent is one or more of water and water-miscible organic solvents.

[0093] In particular, the water-miscible organic solvent is an alcoholic solvent.

[0094] In the above step one, the addition method of the polyethylene glycol and the solvent is not particularly limited, and can be selected and set according to actual needs.

[0095] In a preferred embodiment, the polyethylene glycol is added into the container, and then the solvent is added in...

Embodiment 1

[0174] Centrifugation of polyethylene glycol

[0175] (1) Weigh 25.00g of polyethylene glycol 1000 and heat it at 60-80°C to melt it completely;

[0176] (2) Pour the completely melted polyethylene glycol into a centrifuge tube, place it in a centrifuge and centrifuge for 10 minutes, wherein the rotation speed is 20000 rpm / min, and the centrifugation temperature is 24°C.

Embodiment 2

[0178] (1) At room temperature, weigh 9.40 g of Polyethylene Glycol 1000 and 0.60 g of water obtained through the treatment in Example 1, first add 9.4 g of Polyethylene Glycol 1000 into the beaker, and then add the weighed solution dropwise. water;

[0179] (2) After uniformly mixing polyethylene glycol 1000 and water, the phase change cold storage composite material I was prepared.

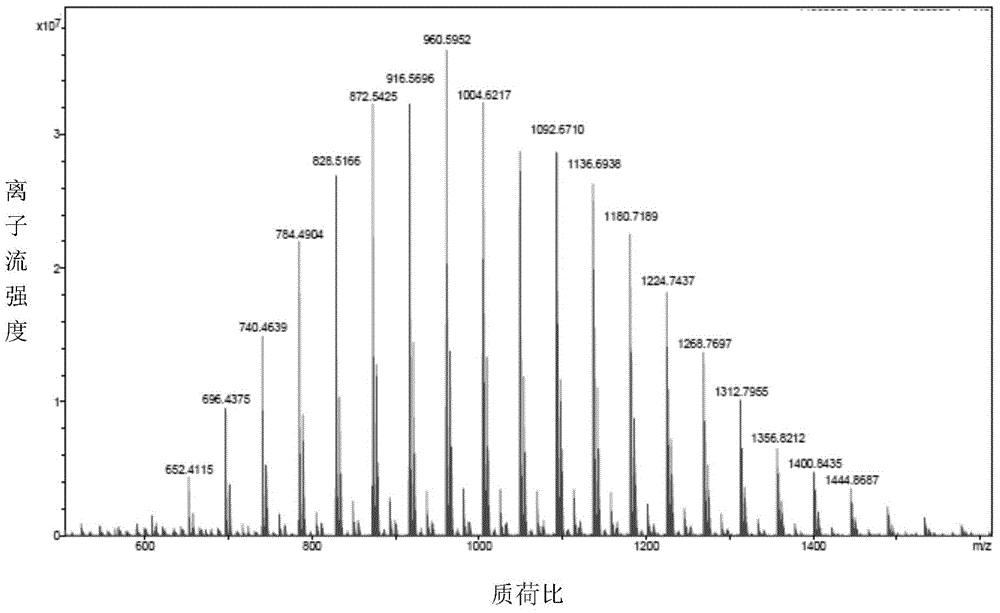

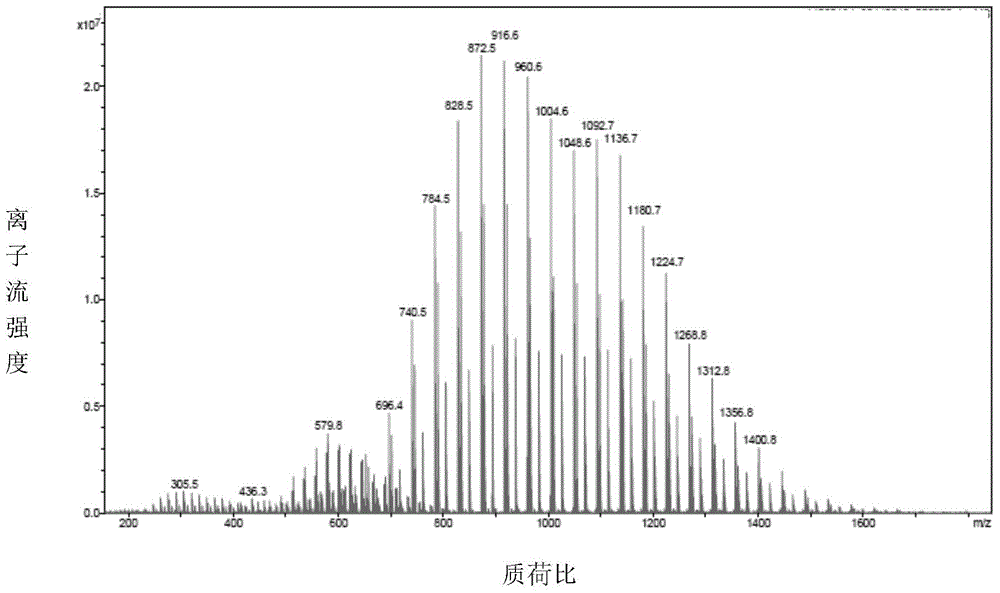

[0180] After the infrared test of material Ⅰ, the infrared characteristic peaks are as follows:

[0181] 3438cm -1 (OH stretching vibration), 2872cm -1 (CH 3 Symmetric stretching vibration), 1648cm -1 (Liquid H 2 O variable angle vibration), 1466cm -1 (CH 2 variable angle vibration), 1434cm -1 , 1280cm -1 , 1242cm -1 (C-O-C anti-symmetric telescopic), 1090cm -1 (alcohol COH expansion and contraction), 947cm -1 (C-O-C symmetrical telescopic), 841cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat of phase change | aaaaa | aaaaa |

| Heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com