Oil-resistant and anti-aging protective coating for rubber shock absorber and preparation method thereof

A protective coating, carbodiimide technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the hidden dangers of power equipment safety and reliability, rubber vibration reduction effect, bearing capacity And other mechanical properties and performance degradation and other problems, to achieve the effect of good bonding force and adaptability, high flexibility, excellent resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Synthesis of polyaspartic ester for component A of oil-resistant and anti-aging protective coatings for rubber vibration isolators: first add 33.00 kg of isophorone diamine and 20.00 kg of diethylene triamine, and pass nitrogen gas. Slowly add 47.00 kg of dibutyl maleate, and keep the temperature at about 40°C. After the reaction is completed, react for about 5 hours, vacuum filter, and discharge the material to obtain the oil-resistant and anti-aging protective coating for rubber vibration isolators. aspartate.

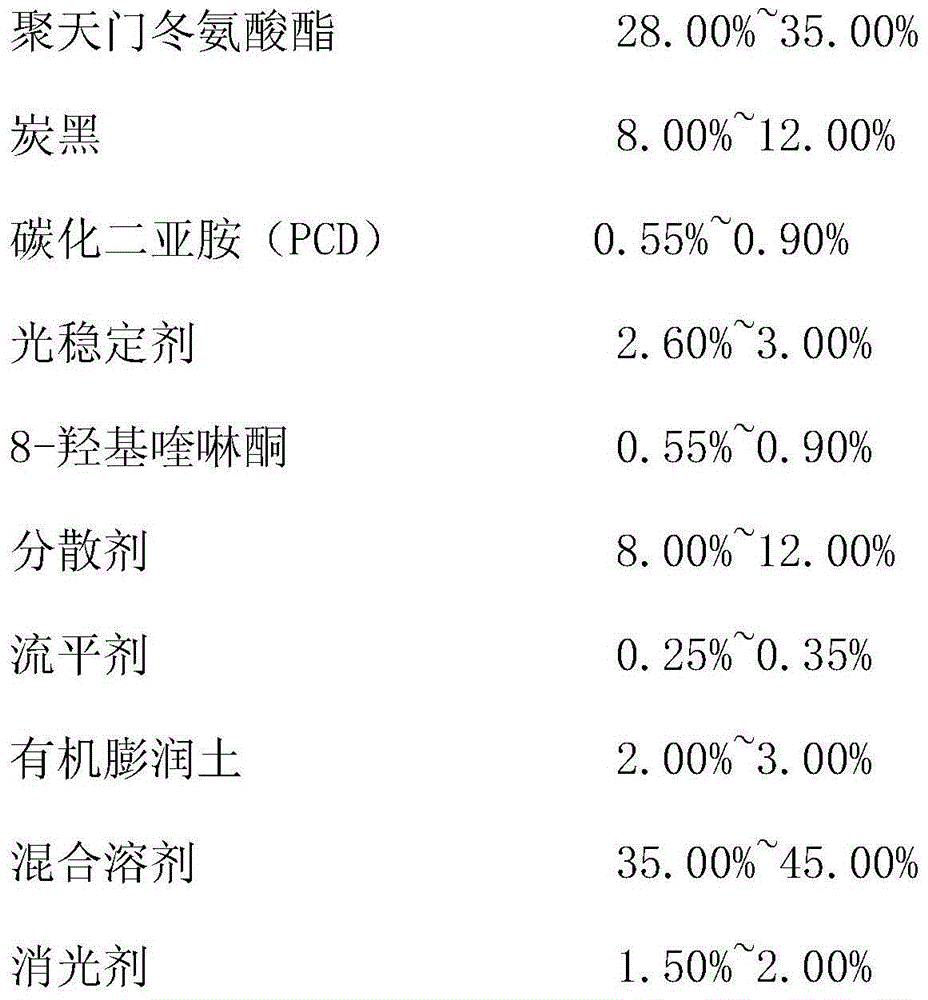

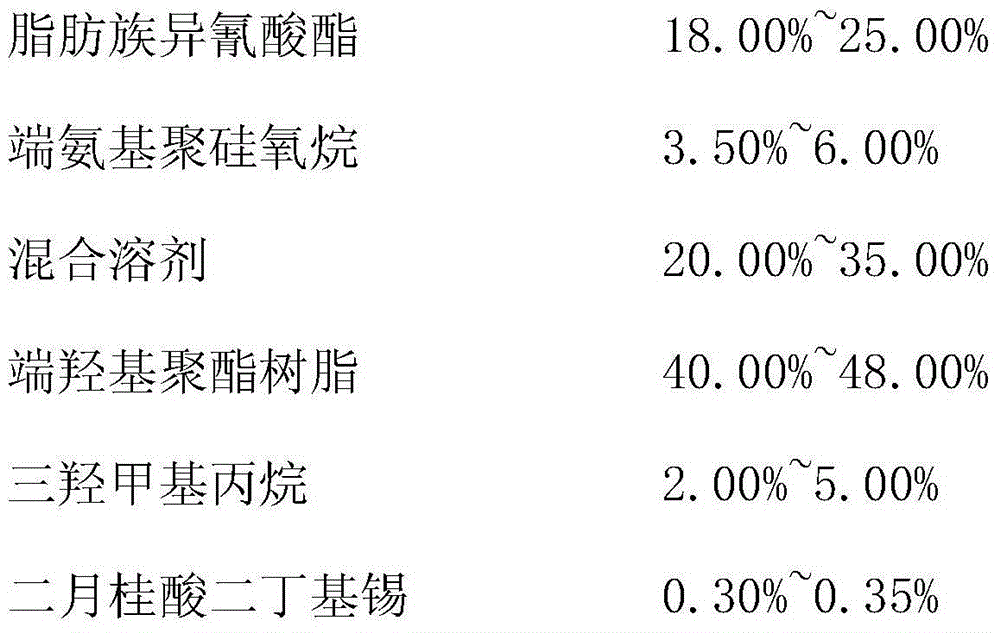

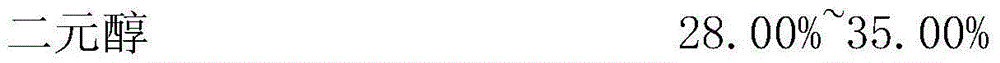

[0046] (2) Preparation of component A of oil-resistant and anti-aging protective coatings for rubber vibration isolators: first mix 9.20kg BYK-163, 0.31kg BYK-307, 0.67kg carbodiimide, 2.90kg 4-benzoyloxy-2,2, Add 6,6-tetramethylpiperidine and 0.67kg of 8-hydroxyquinolinone into a mixed solvent consisting of 11.00kg of butanone, 10.00kg of xylene and 20.00kg of propylene glycol methyl ether acetate, stir well and add 2.15kg of organic bentonite , 9.20kg o...

Embodiment 2

[0051] (1) Synthesis of polyaspartic ester for oil-resistant and anti-aging protective coatings for rubber vibration isolators: first add 35.00 kg of isophorone diamine and 18.00 kg of diethylene triamine, and then pass in nitrogen, slowly Slowly add 47.00 kg of dibutyl maleate, and keep the temperature at about 40°C. After the reaction is completed, react for about 5 hours, vacuum filter, and discharge the material to obtain polytianmen for component A of oil-resistant and anti-aging protective coatings for rubber vibration isolators. aspartate.

[0052] (2) Preparation of component A of oil-resistant and anti-aging protective coatings for rubber vibration isolators: first mix 10.00kg BYK-161, 0.30kg BYK-358N, 0.60kg carbodiimide, 2.70kg 4-benzoyloxy-2,2, Add 6,6-tetramethylpiperidine and 0.60kg of 8-hydroxyquinolinone into a mixed solvent consisting of 10.00kg of butanone, 20.00kg of 0-butyl acetate and 10.00kg of methyl isobutyl ketone, stir well and add 2.00kg Organic ben...

Embodiment 3

[0057] (1) Synthesis of polyaspartic acid ester for oil-resistant and anti-aging protective coatings for rubber vibration isolators: first add 31.50 kg of isophorone diamine and 21.00 kg of diethylene triamine, and then pass in nitrogen, slowly Slowly add 47.50 kg of dibutyl maleate, and keep the temperature at about 40°C. After the reaction is completed, react for about 4 hours, vacuum filter, and discharge the material to obtain polytianmen for component A of oil-resistant and anti-aging protective coatings for rubber vibration isolators. aspartate.

[0058] (2) Preparation of oil-resistant and anti-aging protective coating component A for rubber vibration isolators: first, 11.30kg BYK-P104S, 0.27kg BYK-358, 0.60kg carbodiimide (PCD), 2.70kg hexamethylphosphoric triamide , 0.60kg8-hydroxyquinolinone is added in the mixed solvent that is made up of 8.00kg methyl ethyl ketone, 10.00kg methyl isobutyl ketone and 20.00kg propylene glycol methyl ether acetate, after stirring well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com