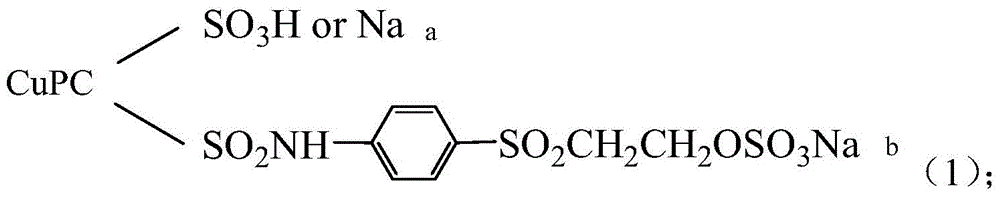

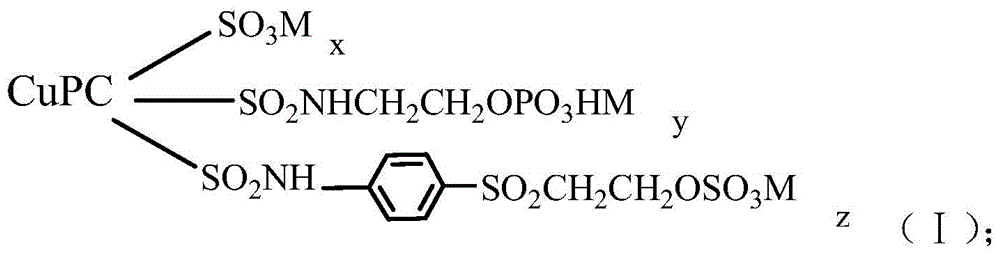

A kind of emerald blue water-soluble dye and preparation method thereof

A water-soluble dye and blue technology, applied in the direction of azo dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of poor salt and alkali resistance, high molecular planarity, unstable dyeing, etc., and achieve excellent performance , Good salt resistance, the effect of improving salt and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

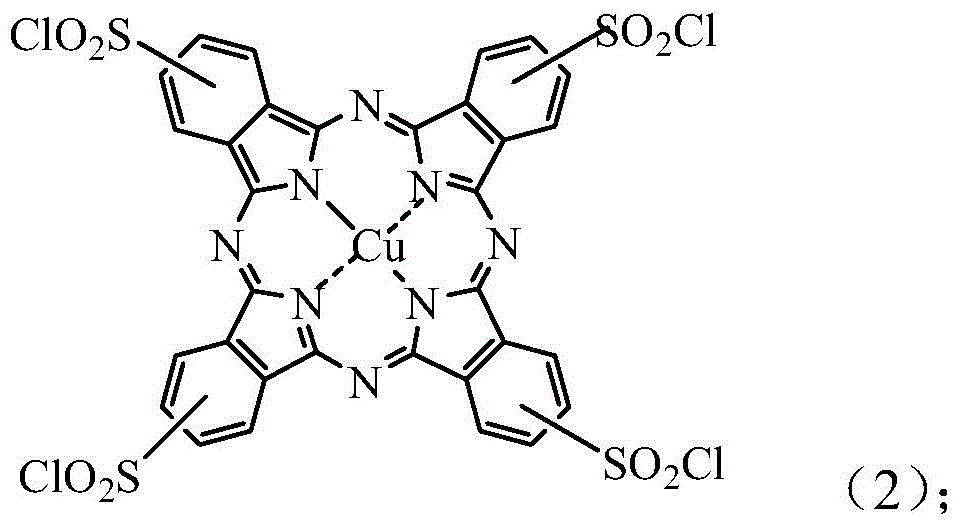

Embodiment 1

[0043] (a) Sulfonation reaction: Add 2200 kg of chlorosulfonic acid to the dry 1# reaction pot, start stirring, slowly add 576 kg of copper phthalocyanine, control the temperature below 90°C during the feeding process, stir for 60 minutes, and wait for the material After all the materials are dissolved, transfer all the materials to the 2# reaction pot, start stirring the 2# reaction pot, heat it slowly with steam, raise the temperature to 116°C within 2 hours, and keep it at 115-117°C for 5 hours, after the heat preservation reaction is completed Cool down to 60°C with cooling water, add 600 kg of thionyl chloride dropwise within 2 hours, and control the temperature at 60-65°C during the dropwise addition of thionyl chloride, stir for 2 hours after the addition of thionyl chloride, and use Heat the steam to 100°C, and keep it warm at 99°C-101°C for 3 hours, use compressed air to blow air from the bottom valve of 2# reaction pot, and bubble for 5 hours, after blowing and bubbli...

Embodiment 2

[0050] (a) Sulfonation reaction: Add 2400 kg of chlorosulfonic acid to the dry 1# reaction pot, start stirring, slowly add 576 kg of copper phthalocyanine, control the temperature below 90°C during the feeding process, stir for 60 minutes, and wait for the material After all the materials are dissolved, transfer all the materials to the 2# reaction pot, start stirring the 2# reaction pot, heat it slowly with steam, raise the temperature to 118°C within 2 hours, and keep it at 117-119°C for 5 hours, after the heat preservation reaction is completed Cool down to 60°C with cooling water, add 540 kg of thionyl chloride dropwise within 2 hours, and control the temperature at 60-65°C during the dropwise addition of thionyl chloride, stir for 2 hours after the addition of thionyl chloride is completed, and use Heat the steam to 105°C, keep it warm at 104-106°C for 3 hours, use compressed air to blow air from the bottom valve of 2# reaction pot, and bubble for 5 hours, after blowing an...

Embodiment 3

[0057] (a) Sulfonation reaction: Add 2050 kg of chlorosulfonic acid to the dry 1# reaction pot, start stirring, slowly add 576 kg of copper phthalocyanine, control the temperature below 90°C during the feeding process, stir for 60 minutes, and wait for the material After all the materials are dissolved, transfer all the materials to the 2# reaction pot, start stirring the 2# reaction pot, heat it slowly with steam, raise the temperature to 121°C within 2 hours, and keep it at 120-122°C for 5 hours, after the heat preservation reaction is completed Cool down to 60°C with cooling water, add 720 kg of thionyl chloride dropwise within 2 hours, and control the temperature at 60-65°C during the dropwise addition of thionyl chloride, stir for 2 hours after the addition of thionyl chloride is completed, and use Heat the steam to 103°C, keep it warm at 102-104°C for 3 hours, use compressed air to blow air from the bottom valve of 2# reaction pot, and bubble for 5 hours, after blowing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com