Silica sol/polyacrylic ester emulsion with high silicon content and preparation method of silica sol/polyacrylic ester emulsion

A technology of polyacrylate emulsion and silica sol, which is applied in the direction of coating, etc., can solve the problems of poor compatibility and easy agglomeration, and achieve the effects of outstanding water resistance, high adhesion and reduced particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

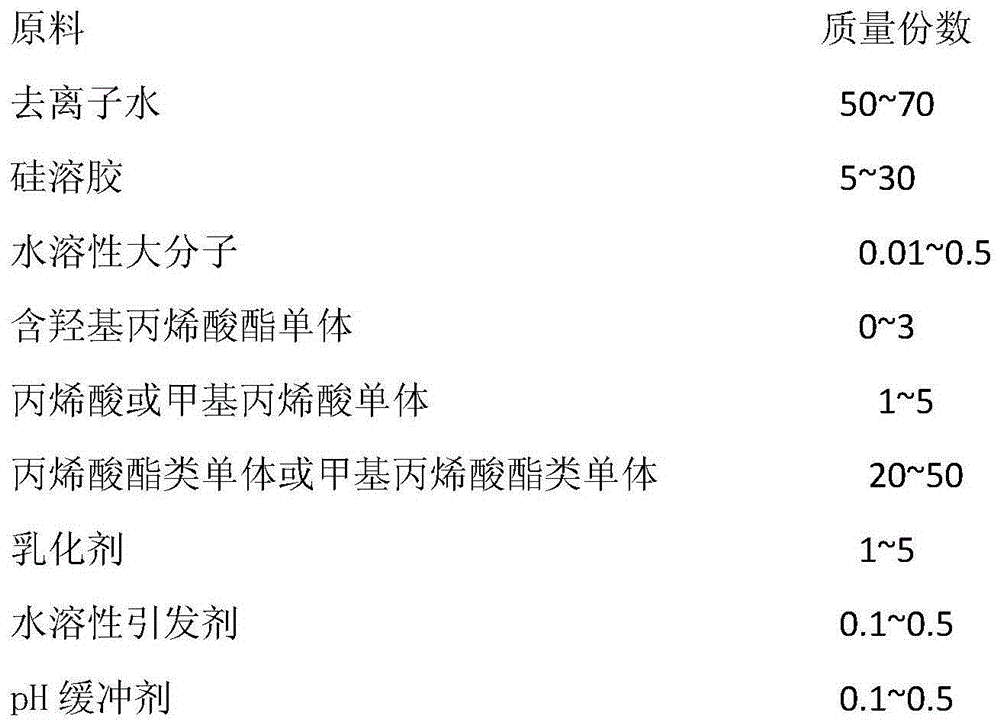

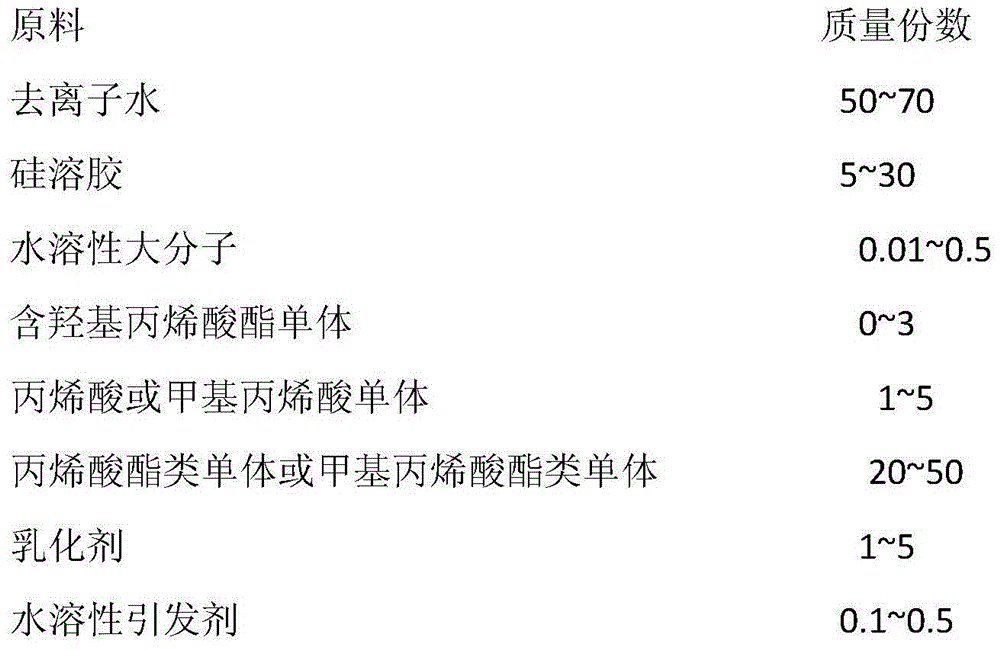

Method used

Image

Examples

Embodiment 1

[0043] Dissolve 0.18g of HEC into 5g of deionized water, then add the HEC solution to 56g of silica sol, and stir and react at 41°C for 12h to obtain modified silica sol.

[0044] 3.2g DNS-86 (allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate) and X-405 (octylphenol polyoxyethylene ether) compound emulsifier (mass ratio: 2:1) Dissolved in 38g deionized water to obtain an emulsified solution, which was divided into three parts: take 8g as the core monomer emulsifier solution, 25g as the shell monomer emulsifier solution, and mix the remaining emulsifier solution with the modified silica sol as the kettle liquid .

[0045] Monomer pre-emulsification: Add the core monomer emulsifier solution and the shell monomer emulsifier solution into two jars respectively, stir for 25min at a speed of 1500rpm, then drop 11g of the core monomer into the two bottles respectively ( The mass ratio of methyl methacrylate and butyl acrylate is 1:1) and 32.2g shell monomer (...

Embodiment 2

[0050] Dissolve 0.01 g of HEC into 5 g of deionized water, then add the HEC solution to 30 g of silica sol, and stir and react at 41° C. for 12 hours to obtain modified silica sol.

[0051] Dissolve 1.6g of DNS-86 and OP-10 (nonylphenol polyoxyethylene ether) composite emulsifier (mass ratio: 2:1) in 20g of deionized water, and divide it into three parts: take 3g as nucleomonomer emulsifier Solution; 11g is the core monomer emulsifier solution; the rest of the emulsifier solution is mixed with modified silica sol as the kettle liquid.

[0052] Monomer pre-emulsification: Add the core monomer emulsifier solution and the shell monomer emulsifier solution into two jars respectively, stir for 15 min at a speed of 1500 rpm, then drop 7g of the core monomer into the two bottles respectively ( The mass ratio of methyl methacrylate and butyl acrylate is 1:1) and 23g shell monomer (the mass ratio of methyl methacrylate, butyl acrylate, methacrylic acid and hydroxypropyl methacrylate is...

Embodiment 3

[0055] Dissolve 0.08g PEG (molecular weight 20,000, Guangdong Guanghua Chemical Factory Co., Ltd.) into 5g deionized water, then add the PEG solution to 25g silica sol, stir and react at 60°C for 10h to obtain modified silica sol.

[0056] Dissolve 3.5g of SVS (sodium vinyl sulfonate) and AEO40 (fatty alcohol polyoxyethylene ether emulsifier) compound emulsifier (mass ratio: 1:4) in 25g of deionized water, and divide it into three parts: take 5g as the nucleus Monomer emulsifier solution, 15g is used as shell monomer emulsifier solution, and the remaining emulsifier solution is mixed with modified silica sol as kettle liquid.

[0057] Monomer pre-emulsification: Add the core monomer emulsifier solution and the shell monomer emulsifier solution into two jars respectively, stir for 10 min at a speed of 1500 rpm, then drop 7g of the core monomer (methyl methacrylate and The mass ratio of butyl acrylate is 1:1) and 23g shell monomer (the mass ratio of methyl methacrylate, butyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com