Flame retardant compound, flame retardant epoxy resin and flame retardant composition

An epoxy resin, flame retardant technology, applied in the field of flame retardant substances, can solve the problems of being unsuitable for high multi-layer, high reliability, high adhesive processing performance, disadvantage, etc., and achieve good flame retardancy and good heat resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

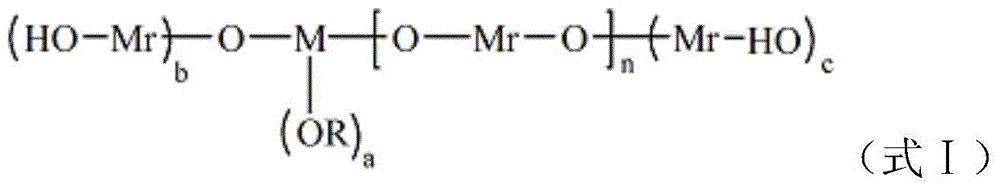

Method used

Image

Examples

Embodiment 1

[0042] Add 173.83g (0.5mol) of hexachlorocyclotriphosphorcyanate, 150ml of acetone, 100.06g (2.0mol) of sodium methylate and 242g (2.2mol) of hydroquinone into a three-port 1000ml glass reactor with a stirring device, while stirring, While blowing nitrogen, raise the temperature to 45°C, add 400g of 20% sodium hydroxide solution dropwise over 60 minutes, keep the temperature at 45°C, and stir for 12 hours. After the reaction, remove the moisture in the system by physical means, filter and remove the insoluble matter in the system, and distill off the solvent in the system to obtain 558.0 g of a new standard flame-retardant substance shown in general formula (II), and measure its phenolic equivalent It is 165g / eq, and this target product is named as A.

Embodiment 2

[0044] Put 180g of dichloroethane, 104.11g (0.5mol) of phosphorus pentachloride, 26.75g (0.5mol) of ammonium chloride and 20g of magnesium chloride into a three-port 1000ml glass reactor with a stirring device. Heat up to 60°C while stirring and blowing nitrogen, and react at 60°C for 6 hours, then add 100.06g (2.0mol) of sodium methoxide and 242g (2.2mol) of hydroquinone to continue the reaction for 8 hours , add 250g of solvent, remove the insoluble matter by filtration, and then evaporate the solvent to obtain 556.8g of the new flame retardant substance shown in the general formula (II), and its phenolic equivalent is 164g / eq. The product of this purpose is named as b.

Embodiment 3

[0046] (1) in the three mouthful 500ml glass reactors that have stirring device, drop into the triphenylphosphine that epoxy equivalent is the liquid bisphenol A type epoxy resin 374g of 187g / eq and object A material 38g and 0.1g, is warming up to 120 ℃, reacted for 5 hours, and the epoxy equivalent obtained was 412g of the object epoxy resin of 232g / eq, then added acetone and modulated into a 60% epoxy resin solution, and this object was named as C.

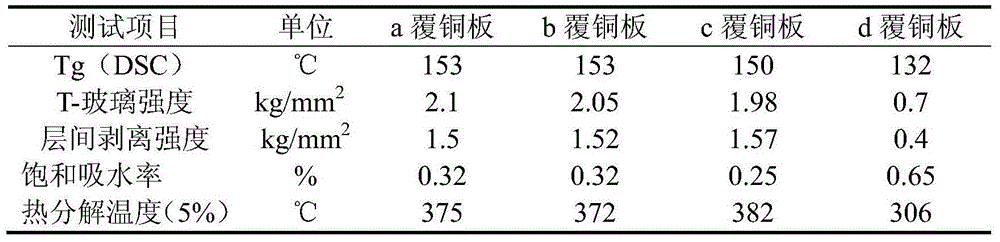

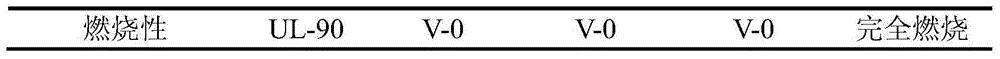

[0047] (2) Take 100g of the solution of substance C (solid content is 60g), then add 3.0g of dicyandiamide and an appropriate amount of DMF, after stirring uniformly, add 0.08g of 2-methylimidazole to make a solution, and then follow the general The standard copper clad laminate samples conforming to the national standard, UL and other standards are prepared according to the production procedure of the copper clad laminate, named a copper clad laminate, and the performance of the a copper clad laminate is tested, and the results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com